Researcher: YAMAMOTO Takahiro, Senior Researcher, Smart Materials Group, Research Institute for Sustainable Chemistry

The researcher has developed technology for photochemical control of adhesion by mixing liquid crystal components into paint materials, in collaboration with TAT Inc. It was demonstrated that adhesion strength is greatly reduced by irradiation with near-ultraviolet light. Application is expected to peeling-off technology that does not use solvents.

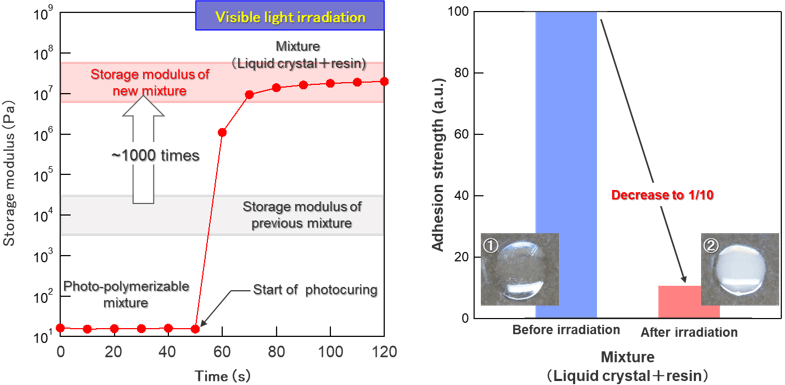

Change in hardness (storage modulus) of new mixture upon photocuring (left) and change in adhesion strength of new mixture upon irradiation with near-ultraviolet light (right)

When using gel nails (artificial nails), a liquid photo-polymerizable material is applied to the fingernails, and is then polymerized and cured by light irradiation to form a coating film. However, an organic solvent is needed to peel off this coating film, which poses health and safety issues. Methods that use acidic or alkaline aqueous solutions have been proposed, but have yet to achieve practical use. Development of removal technology that does not use organic solvents has been desired.

The developed material is a mixture of resin and liquid crystal mixed with a photo-polymerizable substance. When this mixture is cured by irradiation with visible light (wavelength: 405 nm) for 3 minutes, the storage modulus, which is an indicator of hardness, increases to approximately 1000 times that of previous mixtures. In addition, liquid crystal components of non-azobenzene compounds were investigated, and a colorless, transparent mixture was developed. It was demonstrated that when this mixture after photo-polymerization is irradiated by near-ultraviolet light (wavelength: 365 nm) for 10 minutes, the adhesion strength decreases to 1/10.

The researcher intends to promote collaboration with material manufacturers with the goal of practical application within a several years.