Researchers: TAKAHASHI Akira, Senior Researcher, MINAMI Kimitaka, Senior Researcher, and KAWAMOTO Tohru, Leader, Nanoparticle Functional Design Group, Nanomaterials Research Institute

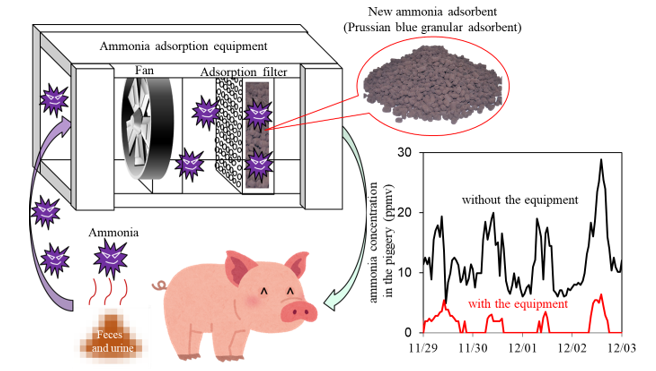

Adsorption equipment filled with an ammonia adsorbent was developed for malodor removal, in cooperation with Kanto Chemical Co., Inc. The effectiveness of the equipment was verified by pilot plant in a piggery and a composting facility for pig feces and urine.

|

|

Outline of ammonia adsorption equipment for piggeries and results of ammonia removal verification tests |

Ammonia, which is one of malodorous substances, is released into the air mainly from the livestock industry in Japan. Actually, 60% of the total ammonia was released from the livestock industry in the fiscal year 1994 (A. Kannari et. al. J. Jpn. Soc. Atoms. Environ. 36, 29 – 38, 2001). The livestock industry requires the removal of ammonia from the perspective of preventing malodors in the surrounding area. To date, biological methods, e.g. biofilters and soil filter, are being used in some livestock facilities for this purpose. With these biological methods, large-size equipment is required owing to the large amount of ammonia. Therefore, more compact equipment was demanded in the livestock industry. In addition, removing malodorous substances from the atmosphere inside piggery is expected to improve the pig production efficiency.

More than 70 different Prussian blue analogues were synthesized and evaluated in order to develop a low-cost and reusable adsorbent intended for actual uses. The results showed that these requirements were satisfied with copper Prussian blue. In which, one of the two types of iron ions in Prussian blue is replaced with a copper ion.

Following this, a granular adsorbent of diameter 3-5 mm consisting of copper Prussian blue and a binder was developed in order to load copper Prussian blue into adsorption equipment easily. The granular adsorbent showed high adsorption performance as of the powder of copper Prussian blue. In addition, the granular adsorbent was not broken in the regeneration process, showing adequate mechanical strength in actual uses.

In the future, the researchers will evaluate the effect on improving the efficiency of pig growth resulting from the removal of ammonia. In addition, practical applications of the ammonia recovered from livestock facilities will be studied.