Masashi Kuwahara (Senior Researcher) of Mesoscopic System Group (Leader: Reiko Azumi), the Electronics and Photonics Research Institute (Director: Satoshi Haraichi) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), has developed an instrument enabling simple and easy measurement of the refractive index of high-temperature molten materials in collaboration with Fukuyoshi Morikasa (Division Manager) of Sales engineering division, THERMO RIKO CO., LTD. (Thermo Riko; Representative Director: Tomoyoshi Endo), Koichi Tsutsumi (Technical Chief) of J.A. Woollam Japan Corporation (Woollam; Representative Director: Michio Suzuki), and Masahiro Susa (Professor) and Rie Endo (Assistant Professor) of Department of Metallurgy and Ceramics Science, Graduate School of Engineering, Tokyo Institute of Technology (Tokyo Tech; President: Kenichi Iga).

The instrument has been developed through fusion of the infrared heating technology of Thermo Riko, the spectroscopic ellipsometer technology of Woollam, and the containment technology for high-temperature molten materials of AIST and Tokyo Tech. The instrument makes it possible to conduct simpler and easier measurement of the refractive index of high-temperature molten materials than conventional instruments. It is thereby expected to contribute to the development of optical information devices and the precise control of metal refining processes.

Details of this technology will be presented at the Joint International Symposium on Optical Memory and Optical Data Storage Topical Meeting (ISOM/ODS 2011) to be held on the island of Kauai, Hawaii, USA, from July 17 to 21, 2011.

|

|

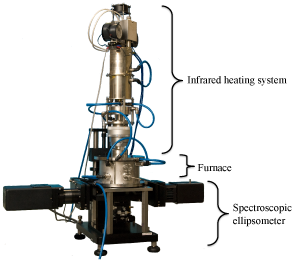

Figure : The developed instrument for refractive index measurement

|

High-temperature molten states are liquid states occurring in material refining processes and optical disk writing and reading processes. A high-temperature melting process of materials is frequently used in material refining. In the field of optical disks, in particular rewritable optical disks, the process of melting the materials making up the thin film on the disk through the irradiation of laser light and rapidly cooling them is essential when writing or reading a disk. A variety of evaluation of materials at high temperatures is therefore indispensable to the efficient control of processes and the structural design of products.

Evaluation of the refractive index of a material is one of the important evaluation methods. The refractive index is essential for the calibration of the radiation thermometers used in refining processes, and in determining how an optical disk will respond to laser light. However, it is very difficult to measure the refractive index of a molten material at a high temperature for a variety of reasons. The reasons include the fact that high temperatures make it impossible to touch the material when adjusting the measurement, and that high temperatures cause materials to evaporate and/or react with air. Because of this, measurements have only been able to be conducted under extremely limited conditions, with individuals sufficiently experienced in the use of highly specialized instruments performing measurements for specific materials.

AIST worked towards the development of an evaluation method of refractive indexes in cooperation with Thermo Riko, Woollam, and Tokyo Tech. In terms of main roles in these efforts, Thermo Riko was responsible for developing the heating section and the heating furnace; Woollam for developing the optical system and the method of analysis; and Tokyo Tech and AIST for developing the sample preparation method, designing the instrument, and developing cells for high-temperature melting. The researchers have succeeded in measuring the refractive index of recording materials for optical disks in molten states at high temperatures.

Part of this research was supported by Technical Development for Small and Medium Enterprises (FY2008-2009), sponsored by the Ministry of Economy, Trade and Industry, and by a Grant-in-Aid for Scientific Research (Scientific Research (B)) provided by the Japan Society for the Promotion of Science.

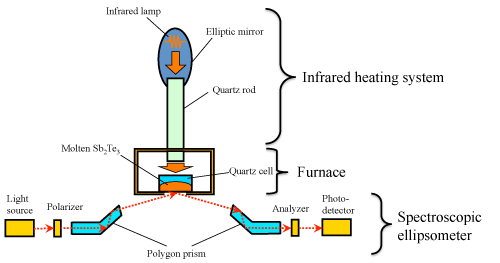

Figure 1 shows the configuration of the developed instrument. An infrared heating apparatus is used to heat the sample. This apparatus concentrates the infrared light produced by a powerful lamp with a maximum power consumption of 2 kW, rapidly raising the temperature of the sample to more than 1000 °C. The infrared light produced by the lamp is focused by a spheroid mirror, and is guided to a quartz rod. The infrared light passes through the quartz rod, and radiates from the lower end to heat the sample. A heater or other heat-generating devices would also heat the area around the sample, necessitating the use of heat-insulating materials, etc., which would make the instrument too cumbersome. In contrast, heating the sample by concentrating infrared light enables the instrument to be made very compact. A spectroscopic ellipsometer (Woollam M2000) is used to measure the refractive index of the sample. This ellipsometer is very sensitive, and is able to measure the refractive index of the mono-atomic layer at the surface of a material.

|

|

Figure 1 : Overview of the developed instrument |

The handling of materials in a molten state at high temperatures presented issues in terms of the ability to conduct stable measurement. One of these issues was the fact that materials cannot be heated in air because evaporation and/or oxidation occur in molten materials at high temperatures. AIST and Tokyo Tech resolved this issue by vacuum-sealing the sample in a container manufactured from quartz (a quartz cell). Optimization of the shape, thickness, and the production method of the cell enabled the production of cells withstanding severe measuring conditions. The second issue was creating the flat surface necessary for the measurement by the spectroscopic ellipsometer. If the surface was not flat, the incident light would be scattered in various directions, and the measurement would be impossible. In order to resolve this issue, a flat surface was provided utilizing the force of gravity that causes the molten sample to follow the shape of the cell floor and become flat. As shown in Fig. 1, the incident light is guided to the bottom of the quartz cell using the total reflection of a polygonal prism, and the light reflected from the sample is also guided to the detector by another polygonal prism. If mirrors were used instead of the prisms, the signal due to mirror materials would overlap with the signal of the sample and analysis would be impossible. In the case of the total reflection of prisms, the measurement results can be analyzed after subtracting a fixed value. A silicon substrate and a thin gold film with well-known refractive indexes were measured and analyzed using the developed instrument. The results matched the reported refractive indexes, demonstrating the adequate functioning of the light guidance system incorporating prisms.

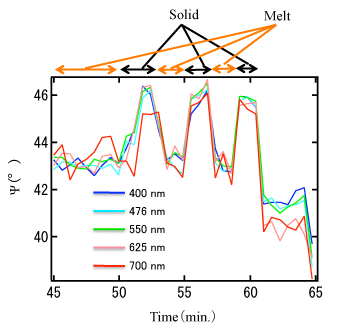

The developed instrument was used to measure the refractive index of Sb2Te3 (melting point: 620 °C), a recording material for optical disks. Figure 2 shows the measured ratios of the intensities of two polarizations of light (expressed as angles) at five typical wavelengths, obtained in order to verify the reproducibility of the measurements by repeatedly melting (at approximately 700°C) and solidifying (at approximately 500°C) the sample. The two polarizations are light with an electric field component perpendicular to the sample (p polarization) and light with an electric field component parallel to the sample (s polarization). Figure 2 shows how p polarization and s polarization change after the light is incident on the sample. When the sample solidifies, the ratio increases, and when the sample is melted it decreases. Measurements were reproducible for three cycles of solidification and melting, indicating that there was no change in properties of the sample and that stable measurements had been achieved.

|

Figure 2 : Reproducibility of measurements when Sb2Te3 is repeatedly solidified and melted

(Measurements completed in 60 minutes.) |

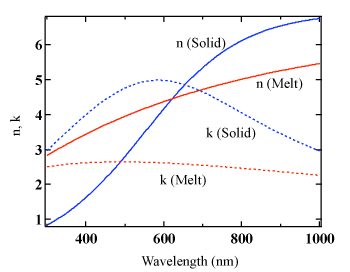

Figure 3 shows the measured and analyzed real part (n) and imaginary part (k) of the refractive indexes in a wavelength region of 300 to 1,000 nm. The blue solid and broken lines respectively show n and k when the sample was solid (at approximately 500°C), and the red solid and broken lines respectively show n and k when the sample was melted (at approximately 700°C). The refractive index of the sample in solid state is almost identical to the reported refractive index of a Sb2Te3 thin film at room temperature. Both n and k of the melted sample differ from those of the solid sample, and k significantly decreases in particular. The imaginary part of a refractive index is called the extinction coefficient and indicates the degree of light absorption of a substance. It is basically zero for a transparent substance. The smaller k of the melted sample means that molten Sb2Te3 was more transparent than solid Sb2Te3. This phenomenon has been experimentally verified for the first time. In addition, it was estimated from the relationship between light absorption and wavelength that solid Sb2Te3 is an indirect transition semiconductor with a band gap of 0.27 eV (corresponding to a wavelength of 4.6 µm) and melted Sb2Te3 is a direct transition semiconductor with a band gap of 1.1 eV (corresponding to a wavelength of 1.1 µm). Because materials tend to become transparent when the band gap increases, it was conjectured that the transparency of melted Sb2Te3 was due to this increase in the band gap.

|

|

Figure 3 : The measured real part (n) and imaginary part (k) of the refractive indexes of solid and molten Sb2Te3 |

Aiming at the commercialization of the instrument in two years, the researchers plan to make the instrument smaller and increase its usability. Woollam will supply the instruments to domestic and overseas metal refining businesses and optical disk manufacturers as the equipment enabling anyone to conduct measurements easily. They also intend to carry out measurements of the refractive index of materials in a high-temperature molten state and to perform theoretical calculations (first principle calculations), thereby analyzing changes in the refractive index from a physical perspective.