Update(MM/DD/YYYY):07/22/2009

New Electric Power Device Developed to Help Enable the Introduction of Numerous Distributed Generators

- Superconducting thin-film current-limiting devices are low-cost, compact, low-loss solutions to suppressing fault current quickly -

Points

-

Fault current caused by a short circuit in the power grid is instantly suppressed using the phenomenon that an overcurrent makes a superconductor into normal-conducting state.

-

500 V/200 A class module is realized using 20-cm-long large-area superconducting oxide films with high-resistivity gold-silver alloy layers.

-

This technology is fundamental to the introduction of numerous distributed generators such as wind power generators, the output of which is unstable, into the power grid.

Summary

Hirofumi Yamasaki (Leader) of the Superconductor Technology Group, the Energy Technology Research Institute (Director: Yasuo Hasegawa), the National Institute of Advanced Industrial Science and Technology (AIST) (President: Tamotsu Nomakuchi) and co-workers have developed a unique 500 V/200 A fault-current limiter (FCL) module, using superconducting films. The FCL will be useful in protecting power facilities from potential damage resulting from fault (short circuit) current when numerous distributed generators are introduced in the future.

The FCL element adopts superconducting films prepared by a metal organic deposition (MOD) technique, which was also developed by AIST. The FCL element shows zero resistance under normal conditions, and can withstand a voltage ≥4 times higher than that conventional devices (using pure gold) of the same length can tolerate, thanks to the high-resistivity gold-silver alloy layers on top of the large-area superconducting oxide films. Cost of FCL will be substantially lowered because the amount of expensive superconducting oxide film needed is reduced to less than one-quarter that for conventional devices.

It has been confirmed that when the module was cooled in liquid nitrogen, a current of 237 A (effective value) flowed with zero electrical resistance. High-voltage switching experiments showed that a prospective fault current of 2.26 kA without the FCL module was instantly reduced to one-third or less, and the module withstood a voltage of ≥500 V for 5 cycles in spite of its short length of 20 cm. By connecting 8 modules in series, we can construct one phase in a three-phase 6.6 kV/200 A FCL. Based on the results, we now have a good prospect of realizing practical superconducting FCLs (of several kV/several 100 A) characterized by low cost, compactness, low loss, and high-speed switching.

The details of this study will be presented at the Cryogenics Society of Japan Conference to be held in Waseda University on May 13-15, 2009, and at the Technical Meeting on Application of Superconductivity (Institute of Electrical Engineers of Japan) to be held in Kyoto University on June 11-12, 2009.

Social Background for Research

Distributed power sources (small- to medium-sized generation plants) using natural energy, such as wind power generators, are being constructed in many places. When they are connected to the existing power grid, the fault current may greatly increase in the event of a short-circuit fault, and the power facility may be damaged. One solution to prevent such incidents would be to adopt active current-limiting devices, fault-current limiters (FCLs), that can instantly suppress the fault current. In addition, FCLs also prevent instantaneous voltage drops that cause severe damage in delicate loads, in which private power generators supply electricity to such loads and are connected to the commercial power grid.

In order to be able to introduce numerous fluctuating power sources, such as wind power generators, the output of which is affected by climate conditions, countermeasures to suppress the fault current will become very important. In the case of wind power generation, the average output is much smaller than the maximum capacity of a generator. As a short-circuit fault current is calculated based on the maximum capacity of a generator, it is expected that the issue of a fault current increase would be much more serious than in the case of thermal power generation only.

An FCL using superconducting thin films shows zero resistance under normal conditions, but becomes highly resistive if a current larger than a critical current flows, so that the overcurrent can be suppressed. This is a new type of power device with the capability of instantly suppressing a fault current in the power grid. To promote introduction of numerous distributed power sources, the social demand for realizing low-cost high-reliability superconducting FCLs is considered to be great. However, a bottleneck for practical applications is the high cost of superconducting films used in thin-film FCLs.

Next-generation metal-based superconducting tapes are widely used in developing FCLs. However, they require tapes that are 100 times longer than the corresponding length of thin films. This is obviously a disadvantage compared with thin-film FCLs from the viewpoint of cost, size, and loss in normal operations.

History of Research

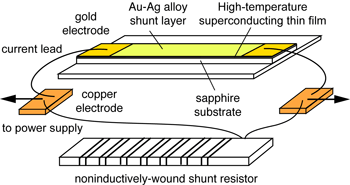

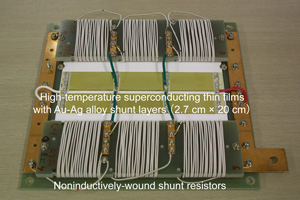

A technical problem with thin-film FCLs is what is called the "hot-spot" phenomenon; that is, local overheating at the point of the earliest quench causes film damage. Here, the "quench" means a quick transition from a superconducting state to a normal-conducting state. AIST proposed a device in November, 2004 in which a gold-silver alloy protective shunt layer, with a resistivity an order of magnitude higher than that of conventional pure gold layer, was sputter-deposited on a superconducting film, and further a low-cost noninductively-wound shunt resistor was connected in parallel to prevent hot spots (Fig. 1). Using a small-capacity device, current-limiting capability was successfully demonstrated. Due to the high resistance of the superconducting thin film, the maximum tolerable voltage per unit length (maximum tolerable electric field) was more than four times higher than conventional devices. The length of a superconducting thin film was reduced to one-quarter or less, showing that the cost of FCLs could be greatly reduced.

Details of Research

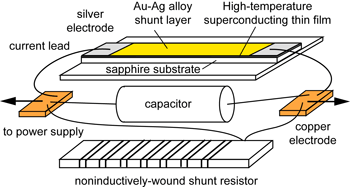

FCLs are used for suppressing fault currents in the power grid, and the rated current for superconducting thin-film FCLs would be ≥200 A even in the case of small-capacity applications in distribution systems, and ≥1k A in the case of trunk transmission systems running at ≥66 kV. It is therefore necessary to use a wider thin film or a parallel connection to increase current capacity, while the hot-spot problem is found to become more serious as the current capacity is increased. To solve the problem, a commercial capacitor is connected in parallel with the thin film to supplement the external shunt resistor in the device (Fig. 2). The external resistor, the capacitor, and the superconducting thin film are all placed in liquid nitrogen. Using a wide thin film corresponding to the rated current of 136 A (effective value), an FCL element with the configuration shown in Fig. 2 was fabricated. In the test, no film damage was detected and a high maximum tolerable electric field was confirmed. As the voltage increases very steeply at the moment of quenching of the superconducting thin film, a high current flows into the capacitor, in spite of its small capacity. As a result, the voltage increase of the thin film is efficiently suppressed, and hot spots are effectively prevented.

Fig. 1 Schematic of the superconducting thin-film FCL element of AIST original |

|

Fig. 2 Hot-spot suppression using a capacitor connected in parallel

|

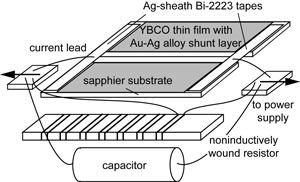

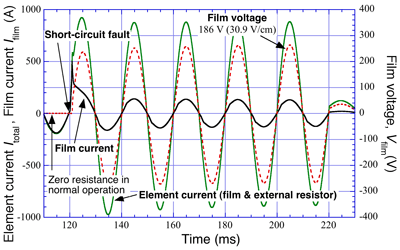

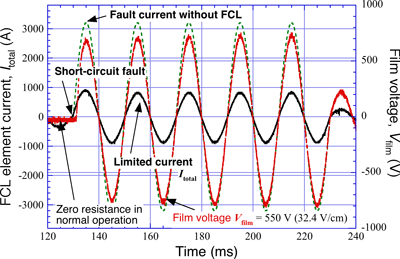

An FCL element was fabricated in which two large-area superconducting YBa2Cu3O7 (YBCO) thin films (effective length 6 cm) prepared by MOD were connected in parallel using superconducting tapes, and then an external resistor and a capacitor were connected in parallel (Fig. 3). After testing the current-carrying capability of 260 A with zero resistance, the current-limiting properties were tested. As shown in Fig. 4, the current, which would become 2.7 kA without the FCL element, is reduced to one-quarter or less, and the limited current flowed for 5 cycles without any film damage under the high electric field of ≥30 V/cm.

Fig. 3 FCL element with superconducting thin films, prepared by MOD, connected in parallel |

|

Fig. 4 Short-circuit test results for a parallel-connected FCL element

|

A YBCO thin film prepared by MOD, 2.7 cm wide and 20 cm long, was divided into three segments by two intermediate electrodes, and an internally-series-connected FCL element was constructed. An FCL module was fabricated by connecting two such elements in parallel (Fig. 5). As the resistance of a noninductively-wound shunt resistor is less than one-fifth that of the superconducting thin film, most of the current flows through the shunt resistor when the thin film quenched. Although not shown in the figure, commercial capacitors with a capacitance of 120 µF are connected in parallel with each segment of the thin films divided into three. If a critical current of ≥280 A is achieved with the two 2.7-cm-wide YBCO thin films connected in parallel, a 500 V/200 A FCL module will be obtained with an effective device length of 17 cm, excepting the electrodes. By connecting 8 modules in series, one phase of 6.6 kV/200 A FCL will be constructed. After confirming the zero-resistance current capacity of 237 A (effective value) for the FCL module shown in Fig. 5, current-limiting tests were performed using a short-circuit generator. A prospective fault current of 2.26 kA without an FCL module is instantly reduced to less than one-third (Fig. 6). A voltage of 550 V is applied across both ends of the thin films, and it is confirmed that a high maximum tolerable electric field (>30 V/cm), which has been obtained in a smaller device with a length of 5-6 cm, is achieved in this 500 V class FCL module. It is also confirmed that the use of a metal-based superconducting tapes at both ends and intermediate electrodes contributes to making the current flow linear and uniform. This serves as another measure against hot spots, and contributes to achieving a target tolerable voltage.

Fig. 5 500 V/200 A superconducting thin-film FCL module |

|

Fig. 6 Current-limiting test results using a short-circuit generator

|

Future Schedule

The results show that a 3-phase 6.6 kV/200 A FCL can be housed inside an ultra-low temperature container with a diameter of 70 cm and a height of 2 m, and the cost of less than two million yen per 1 MW can now be targeted. There still remain challenges for practical applications of superconducting FCLs, such as a greater capacity of over 1 kA class, the control of current-limiting operation and recovery time, and optimized device constitution.

The newly developed current-limiting devices can be used in direct-current applications such as in converter protection. We intend to study such subjects in collaborative projects with private companies.