- Showing the potential application in detecting a variety of diseases and microorganisms -

Hiroshi Uetsuka (Invited Senior Research Scientist) and Nianjun Yang (Post-Doctoral Research Scientist), the Diamond Research Center (Director: Naoji Fujimori) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa) have fabricated vertically aligned nanowire structure with 10 nm lateral spacing on conductive diamond surfaces, and succeeded in highly sensitive detection of DNA (2 pM) using an electrochemical sensor with the nanowire-structured diamond electrodes. The sensor shows several magnitudes of higher sensitivity than those of electrochemical sensors with conventional electrode materials.

Probe DNAs (single strand: 23 mer) are grafted on the apex of diamond nanowires which are aligned vertically with 10 nm spacing on the conductive diamond electrode. When target DNAs are complementary hybridized with the probe DNAs to make double strand chains, redox current should be decreased since the surface area opened for electrolyte will be decreasing. This is the mechanism to detect specific sequence of DNAs using this electrochemical sensor. Two or three order of magnitude higher sensitivity in comparison with conventional sensors using gold or glassy carbon has been achieved.

Several target DNAs can be detectable by changing sequence of probe DNA. Furthermore, the technology can be applicable for detection and measurement of various diseases and microorganisms, and gives our society a big impact.

|

|

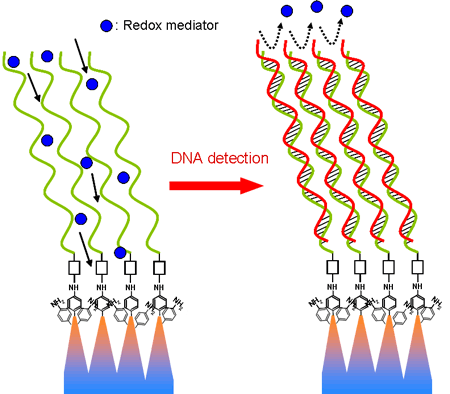

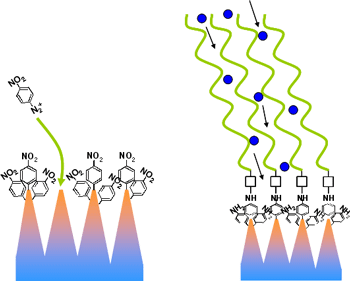

Structure of linker molecules and DNAs fixed on diamond nanowire electrode and principle of DNA detection

Left: Redox mediators can approach the electrode surface through probe DNA layer and react electrochemically (large current)

Right: Redox mediators can not approach the electrode surface due to the narrower interval of DNAs after hybridization (small current)

|

Recently, advanced technology in measurement methods for various biological substances such as DNA, tumor markers, antibodies, and microorganisms etc. related to disease treatment and the safety of food has been required. The development of DNA sensors that can promptly judge with high sensitivity from blood is needed for direct DNA detection.

In addition, durability and stable signal are necessary for sensors in order to measure state in the living body continually, and monitor processes such as food inspection. The chemically stable sensor material and stability of the biomaterial fixed on the sensor surface is required to satisfy above mentioned demands.

Diamond is chemically inert and electrochemically very unique. Moreover, biomolecules such as DNA can be strongly grafted on diamond surfaces, and there is an example of application to a DNA chip.

The biosensor using diamond is classified roughly into the type to use the surface conductive layer and the type to use the electrochemical characteristic. Electrochemical characteristics of diamond have been expected to be applied to the high sensitivity sensor since the range of the electrochemical potential window where the current can be measured is wide and the background current is quite small.

AIST has been investigated modification technology of diamond surface with DNA and established various kinds of immobilizing technology by photochemical and electrochemical reactions. In addition, a much stronger binding between diamond surface and fixed molecules in comparison with fixation to other substrates has been measured and published.

Here, AIST has been applied nano-fabrication process to the diamond surface to develop a sensor which can detect specific sequence of DNA with high sensitivity.

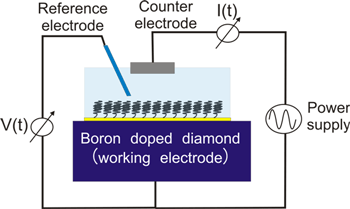

A detection principle of the electrochemical sensor demonstrated high sensitivity is shown in Figure 1. Conductive diamond (boron dope diamond) of 2mm diameter as a working electrode and Pt wire as a counter electrode are fixed in a solution including redox mediator. Electrochemical current generated by redox reaction of ions arriving to the diamond electrode by applyed potential (-1V to 1V) between these electrodes is measured.

|

|

Figure 1 Schematic view of electrochemical DNA sensor using diamond |

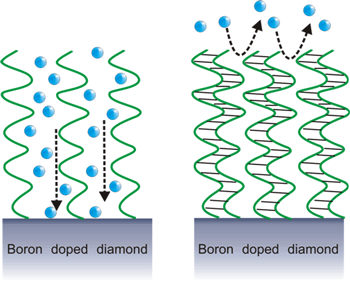

When the clean electrode is measured in this system, an electrochemical characteristic (potential-current curve) specific to the material can be obtained. If DNAs are fixed on the surface, electrode area exposed to the solution decreases and the current becomes small. The redox mediators (ions), however, can easily reach the electrode surface because of wide intervals of DNA when only single strand probe DNA is fixed to the surface as shown in Figure 2 (left). When double helices are formed by hybridization with complimentary target DNAs, the intervals become narrower and the number of ions that can be passed the DNA layer decreases. As a result, the redox current becomes small. The difference between single and double strand DNA can be detected as the amount of the redox current in this way. It is a quite critical factor here to arrange probe DNA with best intervals for the sensitivity improvement.

|

|

Large redox current |

Small redox current |

|

Figure 2 Detection principal of electrochemical DNA sensor |

A further characteristic improvement has been achieved by controlling structure on the diamond surface of this electrochemical sensor in nanometer scale. An interval necessary for single strand DNA to form double strand DNA by hybridization is about 10 nm. Therefore, if single strand DNAs can be arranged with intervals of 10 nm, it is thought that sensitivity becomes the highest since the observed current can be minimized when double strand DNAs are formed.

|

|

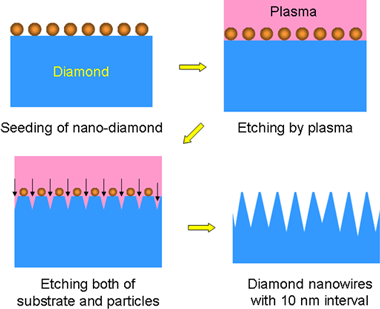

Figure 3 Fabrication process of diamond nanowire structure |

Then, the microfabrication technology to arrange single strand DNAs to the diamond surface with intervals of 10 nm was examined. It is known that the diamond can be easily processed by the oxygen plasma etching. It is impossible to make the sites where DNAs are fixed with intervals of 10 nm by the conventional microfabrication technology used in the semiconductor device fabrication processes. Then, AIST used nano crystalline diamond particles of 10 nm in diameter seeded to the diamond surface as a mask material. Nano-wired diamond surface with the 10 nm intervals can be obtained by using the oxygen plasma for diamond etching. Figure 3 is the schematic illustration of the process.

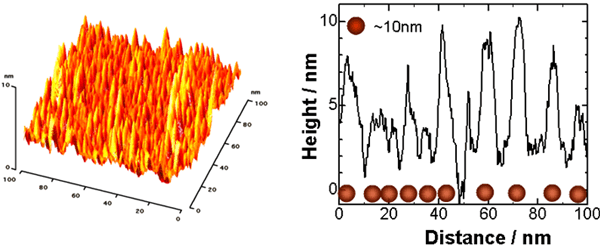

AFM (atom force microscope) image and the cross section of the surface structure of the diamond nanowire surface are shown in Figure 4. It was confirmed that the nanowire structure is really fabricated from the AFM analysis.

|

|

AFM image |

Cross section |

|

Figure 4 Diamond nanowire structure with 10 nm interval |

It is required to place a linker molecule which connects diamond surface and DNA. An electrochemical reduction technique was applied to fix nitrophenyl groups on the diamond nanowire surface. In this reaction, the linker molecules can be selectively fixed on the apex of the nanowires since the electric field is enhanced on the apexes.

The procedure that grafts DNA on the linker molecules has been developed and optimized at the Diamond Research Center in the past. Schematic illustrations of linker molecules and probe DNAs are shown in Figure 5. Here, single strand DNA of the specific sequence of 23 bases was used as probe DNA. The DNA represent a part of genetic codes of a protein known as one of tumor makers. Figure 6 shows the DNA sensor that has the working electrode (2mm in the diameter) made for trial purposes.

Figure 5 Nitrophenyl and DNA grafted on the apex of diamond nanowires |

|

Figure 6 Picture of the DNA sensor

|

|

|

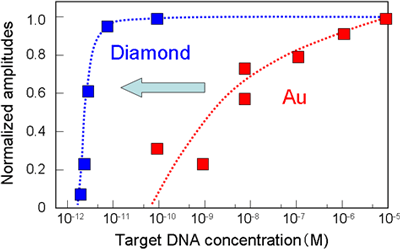

Figure 7 Sensitivity of DNA sensor made of diamond |

Figure 7 shows the relative sensitivity value of the DNA sensor with changing the concentration of target DNA. It was obvious that the target DNA of 2 pM concentration can be detected. Two or three order of magnitude higher sensitivity compared with the conventional sensor made by Au etc. was achieved.

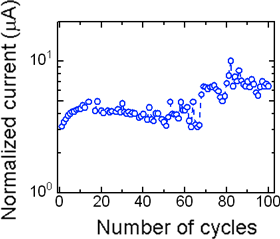

After hybridization, the double strand DNA can be denaturated to single strand DNA by raising the temperature. When long-term stability was examined repeating this hybridization-denaturation cycles, it was confirmed that the sensor performs a steady measurement even in the repetition of 100 times as shown in Figure 8.

|

|

Figure 8 100 times repeated measurements |

In the future, AIST will aim at the development of the sensor with higher sensitivity. It is thought that higher sensitivity will be required for the detection of antibodies and enzymes. A sensitivity in femto-moller range is one of the goal. For this target, the miniaturization of the sensor area is an important issue. Since the dimension of the current sensor is 5 µm, down sizing to 500 nm will be promising to obtain 100 fM sensitvity

How much the influence of the obstruction factor can be decreased is a problem for development of clinical testing. Although any study has not been performed on the detection of specific DNA or protein related with certain disease and micro organisims, AIST is planning to touch into this in the nearest future.