Update(MM/DD/YYYY):08/20/2007

Development of a Nanopipette with an Inner Diameter of 50 nm Using an Organic Nanotube

- Micromanipulation technology made the nanopipette possible -

Points

-

We succeeded in fixing an organic nanotube with an inner diameter of 50 nm onto the tip of a glass micropipette with an inner diameter of 1,800 nm by using micromanipulation technology.

-

The newly developed nanopipette can spout volumes of solution equivalent from one-hundredth to one ten-thousandth of the amount capable of being dispensed by commercial ultrasmall-volume pipette injection systems.

-

We expect the nanopipette to be applicable to medical and analytical use because of its ability to inject or suck ultrasmall volumes of functional materials into or from a single living cell.

Summary

The research group led by Toshio Fukuda (Professor) of the Department of Micro-Nano Systems Engineering, the Graduate School of Engineering (Dean: Katsuaki Onogi), Nagoya University (President: Shinichi Hirano), Fumihito Arai (Professor) of the Department of Bioengineering and Robotics (Dean: Tatsuo Uchida), Tohoku University (President: Akihisa Inoue), and Toshimi Shimizu (Director) and the High-Axial-Ratio Nanostructure Fabrication Team of the Nanoarchitectonics Research Center, the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa) have jointly developed a nanopipette (the ONT nanopipette) that uses an organic nanotube (ONT) as its nanochannel, and which is estimated to be capable of spouting volumes of solution of less than 1 femtoliter (femto- means one quadrillionth : 10–15).

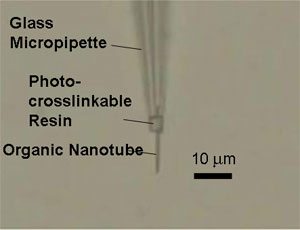

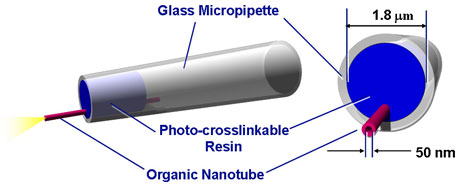

The ONT nanopipette is fabricated by fixing a 10-μm-long ONT of inner diameter 50 nm and outer diameter 400 nm, which forms the nanochannel, to a microglass pipette with an inner diameter of 1.8 μm (1,800 nm) by using micromanipulation technology, and then sealing the interspace between the ONT and the glass micropipette with a photo-crosslinkable resin (Figure 1). The spouted amount from the nanopipette can be controlled by the voltage applied to the nanopipette. This ONT nanotube is expected to be used for medical purposes, because of its ability to inject ultrasmall amounts of useful material into a single cell (a volume of a cell is about 1000 femtoliters) or to suck ultrasmall amount of cell ingredients for single-cell analyses.

The research results will be presented at the 7th IEEE International Conference on Nanotechnology (IEEE-NANO 2007), organized by the Institute of Electrical and Electronics Engineering, Inc., which is to be held in Hong Kong on 2nd–5th of August 2007.

(a)

|

|

(b)

|

|

Fig. 1

|

Social Background of Development

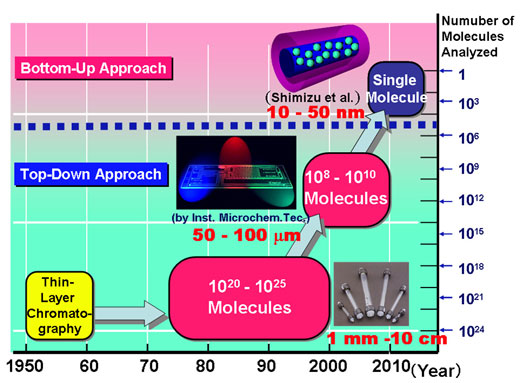

The sizes of hollow cylinder vessels that are used in the analysis of biological molecules have become progressively smaller, from the glass columns with an inner diameter of several centimeters that are used for column chromatography, through stainless-steel columns with an inner diameter of several millimeters used for HPLC, to glass capillaries with an inner diameter of 100 μm (1 μm is one millionth of a meter) and microtip devices (Figure 2).

The number of molecules that can be confined inside the space of these hollow cylinders has become extremely low, and it is now possible to analyze as few as 108–1010 molecules by using a microtip device. It is necessary to build a hollow cylinder with a smaller inner diameter to permit the analysis and handling of fewer than 106 molecules. However, the minimum processible dimensions of existing microfabrication technologies are of the order of several tens of nanometers. Because it is difficult to microfabricate a hollow cylinder with an inner diameter of less than 1 μm for analytical devices, a breakthrough approach is desired.

At present, it is possible to process the tip of a glass pipette to have an inner diameter as small as several tens of nanometers, but the existing approach involves considerable problems in terms of the processing accuracy and the operability of the pipette, particularly in terms of locating the tip.

There are currently three known approaches for producing nanopipettes. The first is to fabricate a nanopipette by affixing a magnetized carbon nanotube to the tip of a glass micropipette by magnet force, the second is to build up a nozzle on the tip of a glass micropipette by means of an surface excitation reaction with a focused ion beam, and the third is to extend the borosilicate glass tube. The first method might create many openings for spouting, and the literature makes no mention of using the nanopipette for dispensing a solution, although aspiration by means of the capillary phenomenon has been demonstrated. The second method is slow and requires a sophisticated system. The third method has problems with limits of resolution and vibration in observations by an optical microscope, because the tip is long.It is also difficult to control the shape of the pipette.

There is therefore a considerable desire to develop a nanopipette with a well-controlled shape and good maneuverability, and ability to spout ultrasmall amounts of solution. We therefore tried to develop a technology for incorporating and fixing a hollow cylindrical structure (ONT) with an inner diameter of less than 100 nm, which is prepared by means of self-assembling, in the “micro-structure”.

|

|

Fig. 2 |

History of Research

The Nanoarchitectonics Research Center of AIST has been aiming to establish a technology for fixing ONT and nanoparticles built by self-assembly technology (a bottom-up approach) onto microtips and microcapillaries built by microfabrication technology (a top-down approach) to create an analytical device with a resolution of several nanometers. Nagoya University and Tohoku University have developed a method for manipulation of single cells by laser operations, and a three-dimensional method using optical tweezers for the manipulation (with six degrees of freedom) of ultrasmall items.

The ONTs developed by AIST’s self-assembly technology were combined with the manipulation method of Nagoya University and Tohoku University in which a micro-manipulation stage was set under a stereo microscope to create nanopipettes.

Development of the three dimensional manipulation technique of Nagoya University and Tohoku University was supported by Grants-in-Aid for Scientific Research of the Ministry of Education, Culture, Sports, Science and Technology. AIST has, for the past ten years, been designing, synthesizing, and developing amphiphilic molecules that self-assemble to form nanotubes. This research was conducted as part of the Solution-Oriented Research for Science and Technology (SORST) project (from FY2005 to FY2008) of the Japan Science and Technology Agency (JST).

Details of Research

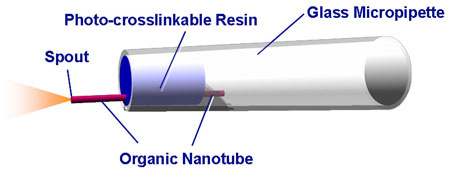

This ONT nanopipette was fabricated by fixing one 10-μm-long ONT (inner diameter 50 nm, outer diameter 400 nm) onto a tip of a glass micropipette with an inner diameter of 1.8 μm by using micromanipulation technology. The ONT works as a nanochannel (Figure 3).

The ONT nanopipette has following advantages.

(1) The nanopipette can be manipulated and observed in the same way as in case of a conventional glass micropipette.

(2) It is easy to focus the observing microscope, because the position of the tip of the nanopipette is very close to that of the glass micropipette.

(3) The nanopipette has excellent strength, because the nanopipette has a tip of the micro-scale glass pipette and the spout of the nano-scale nanotube in the same time.

(4) It can reduce possible vibration.

Thus, the ONT nanopipette has solved longstanding problems of nanopipettes. Furthermore, because the diameter of an ONT is uniform, it is excellent in controlling the nanopipette shape.

|

|

Fig. 3 |

It is another benefit that no expensive, large-scale, special equipment is needed to prepare the nanopipette, because the ONT nanopipette can be built by using standard manipulators with micromotion stages and an optical microscope.

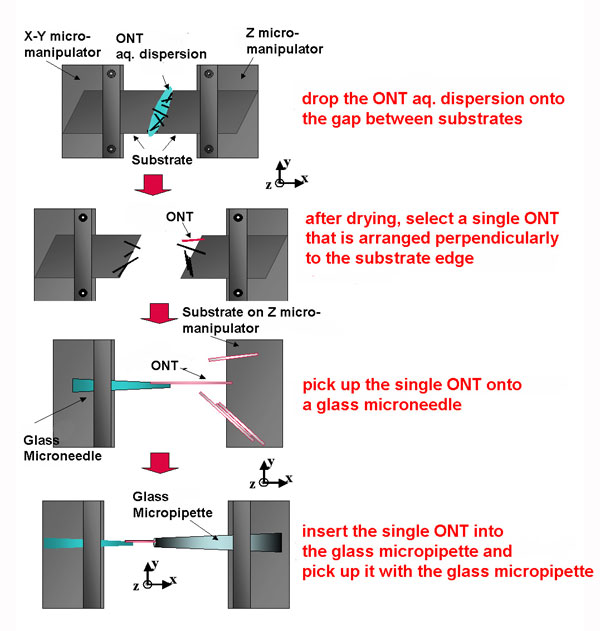

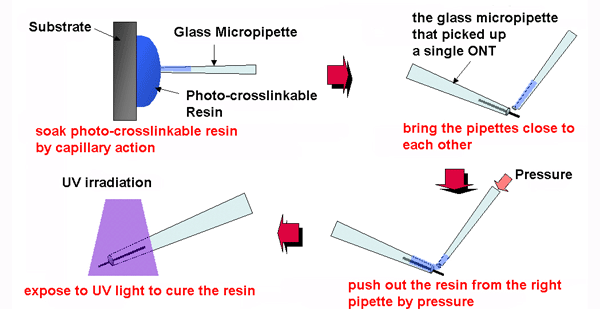

The whole building process can be performed by using the micromanipulation technology while observing the process with an optical microscope (Figure 4). The process can be divided into two operations: the pickup process and the ONT sealing process. The pickup process involves locating the ONT on the inner wall of the glass micropipette [Figure 4(1)], and the sealing process involves sealing the gap between the glass pipette and ONT, and fixing the two together by using a photo-crosslinkable resin. [Figure 4 (2)]

|

Fig.4 |

|

|

4-(1) Pickup process

|

|

|

|

|

4-(2) ONT sealing process

|

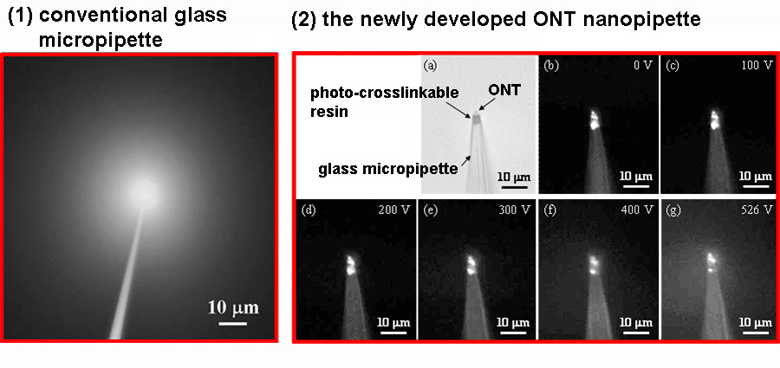

Figure 1(a) is an optical micrograph of the ONT nanopipette. As shown in the micrograph, a nanopipette that combines a tip diameter (1.8 μm) of a micro-scale and a spout (50 nm) of a nano–scale was successfully prepared.

To confirm the effectiveness of the ONT nanopipette, we conducted a spouting experiment with a solution containing Rhodamine 6G, a fluorescent reagent. We spouted the solution by using an electrical migration force, and observed the spouted solution by dark-field fluorescent microscopy with an inverted optical microscope (Figure 5). We confirmed that the nanopipette spouts at above 300 V, and the amount spouted increases gradually with increasing applied voltage. It is also demonstrated that there is a considerable difference in the amount spouted by a conventional glass micropipette with an inner diameter of 1 μm [Figure 5(1)] and that spouted by the ONT nanopipette [Figure 5(2)].

Judging from the results, we concluded that the amount of spouted from the ONT nanopipette can be controlled by changing the voltage, and it is possible to spout ultrasmall amounts of solution (less than 1 femtoliter). This is equivalent from one-hundredth to one ten-thousandth of the amount spouted by a commercial glass micropipette with a 500-nm diameter spout.

As an exploratory experiment, we conducted the same experiment of spouting a solution by using a pipette made by filling the tip of the glass micropipette with the photo-crosslinkable resin, but we were not able to observe any spouting of the fluorescent solution.

|

|

Fig 5 |

Future Schedule

By incorporating the ONT nanopipette into a micromanipulation system under an optical microscope, we aim to use the ONT nanopipette in the biological field as a tool for controlling the local environment, for example, in injecting amounts of a solution of organic substance of less than 1 femtoliter into a singe cell (which has a capacity of less than 1,000 femtoliter), or in aspirating a substance in amounts of less than 1 femtoliter from a single cell.

With this aim in mind, we believe that it is important to develop a method for synthesizing ONTs, which have a well-controlled inner diameter, with a high degree of flexibility. It will also be necessary to examine the condition of the solution for injection, the control of the diffusion of the dispensed solution, and the shape of the electrode to produce an effective electrical migration force.

In addition, we will continue our research and development with the aim of contributing to nanobiotechnology through the approach of organizing a nanostructure in or on a microstructure by developing a technique for merging the bottom-up approach (self-assembling technology) and the top-down approach (microfabrication technology).