Update(MM/DD/YYYY):01/14/2025

Creation of a Novel Bio-based Adhesive Using Euglena-derived Materials to Bond Automotive Structural Components

—Facilitating the recycling of end-of-life auto parts through heat-triggered disassembly—

Researchers) SHIBAKAMI Motonari, Career Researcher, HIMIYAMA Tomoki, Senior Researcher, Biomedical Research Institute, TERASAKI Nao, Team Leader, Sensing System Research Center

Points

- Adhesive made from polysaccharides derived from Euglena and fatty acids

- Adhesive strength similar to that of petroleum-based epoxy structural adhesives

- The bonded aluminum plates can be easily disassembled by heating and re-bonded through reheating.

Strong enough to lift a polar bear: a high-strength bio-based adhesive made from Euglena

Summary

AIST researchers in collaboration with Asahi Kasei Corporation (hereinafter referred to as "Asahi Kasei") have demonstrated that an adhesive comprising polysaccharides (paramylon) extracted from the Euglena cells (hereinafter referred to as "Euglena adhesive") achieves sufficient strength for use in automotive structural materials.

Euglena adhesive is a bio-based adhesive comprising paramylon, which accumulates in large quantities in the cells. It is prepared by adding fatty acids to paramylon. The Euglena adhesive can bond aluminum plates with a strength that surpasses the requirements for aluminum automotive structural materials. This bond strength is similar to that of conventional petroleum-based epoxy adhesives, primarily used for automotive structural materials, and exceeds the bond strengths of previously reported bio-based adhesives.

Conventional adhesives used for automotive structural materials offer high adhesive strength. However, they are difficult to disassemble, thereby making it challenging to dismantle end-of-life vehicles and reuse their parts. By contrast, aluminum plates bonded with the Euglena adhesive can be easily disassembled via heating (easy disassembly). Furthermore, the disassembled aluminum plates can be re-bonded by reheating, thereby achieving nearly the previous levels of adhesive strength.

Waste generated from end-of-life vehicles (ELV) adversely affects the environment. To address this issue, the EU introduced the ELV Directive in 2000 to facilitate the disassembly, reuse, and recycling of vehicle parts. Hence, adhesives with high adhesive strength and easy disassembly properties are required. The newly developed Euglena adhesive, which combines strong bonding performance with easy disassembly, holds promise for addressing environmental challenges posed by ELVs.

Details of this technology were presented on December 6 at the 1st International Conference on Bio-joining, held in Porto, Portugal, from December 5–6, 2024.

Social Context of the Research

Waste generated from ELVs has a considerable environmental impact. To address this issue, the ELV Directive (an EU regulation) was introduced to facilitate the disassembly, reuse, and recycling of vehicle parts. This has created a demand for adhesives that combine high strength with ease of disassembly. Conventional adhesives, such as epoxy adhesives, offer high adhesive strength but lack easy disassembly, thereby leaving the environmental problems posed by ELVs unresolved.

Background of the Research

AIST has been conducting research and development to replace conventional petroleum-based materials with bio-based materials to foster a sustainable, recycling-oriented society. In this effort, we focused on Euglena, a microalga known for its high carbon dioxide fixation capacity and its ability to efficiently use sugar in water as a nutrient source. Euglena accumulates large amounts of a polysaccharide (paramylon) in its cells, using carbon dioxide and sugar as raw materials.

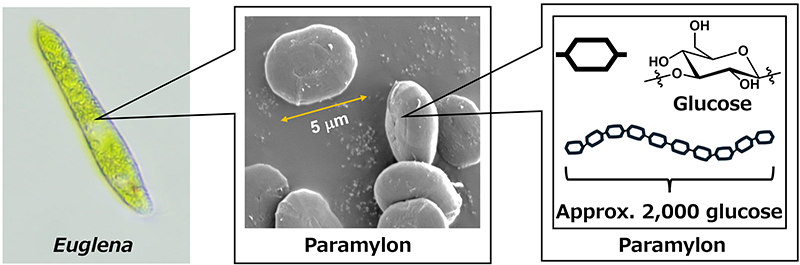

Paramylon is a biological substance that accumulates in large quantities within Euglena cells, making up more than half of the dry cell weight. It is a polysaccharide comprising approximately 2,000 glucose molecules. In Euglena cells, paramylon exists as particles with diameters of a few micrometers, which form by aggregating numerous paramylon molecules (Figure 1).

Figure 1. Euglena and paramylon

The paramylon in these particles is nearly 100 % pure, which renders it chemically modifiable into various materials without requiring the use of complicated purification processes. Euglena cells are surrounded by a soft cell membrane (they do not have a hard cell wall), thereby making it easy to extract paramylon. Furthermore, the Euglena culture offers the advantage of high-density growth, with yields of several dozen grams per liter of culture medium, and it can thrive under acidic conditions that are challenging for other microorganisms.

Over the past 10 years, AIST has investigated the potential use of paramylon as a bio-based material and announced that it can be chemically modified into various materials (AIST press release, January 9, 2013). AIST has developed a comprehensive understanding of the adhesion phenomena and advanced evaluation techniques for adhesive strength. In this study, the AIST group (AIST and AIST Solutions Co.) in collaboration with Asahi Kasei conducted a precise adhesive strength evaluation of the Euglena adhesive and confirmed that it exhibits a high adhesive strength, thereby making it suitable for use as an adhesive in automotive structural materials.

Research Details

AIST has considered paramylon as a raw material for various chemical products, which is similar to the use of naphtha in the petrochemical industry. The institute has been conducting research to develop a variety of materials using paramylon as a starting material, to create a new bio-based manufacturing industry.

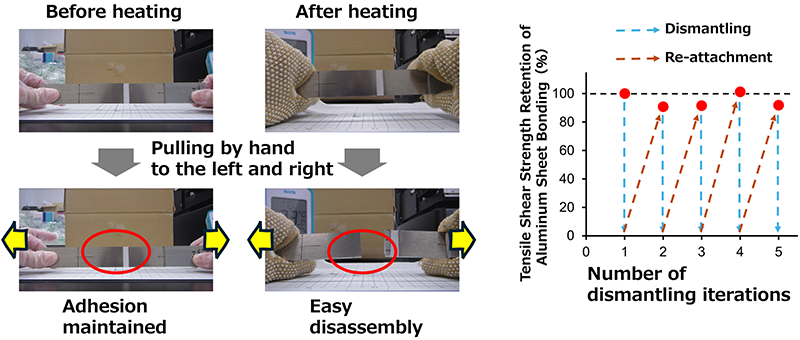

As part of the research and development of paramylon-based manufacturing, AIST and Asahi Kasei confirmed that the Euglena adhesive synthesized by adding a specific amount of naturally occurring fatty acid to paramylon can do the following: (1) strongly bond two aluminum plates using a heating and cooling process; (2) easily disassemble the sheets by reheating; and (3) maintain a similar level of adhesive strength as the initial bond even after multiple adhesion and dismantling processes.

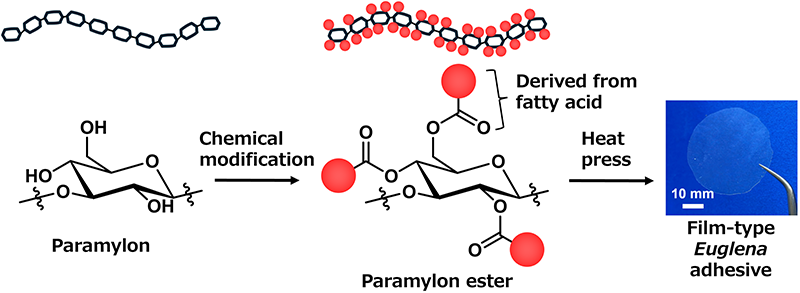

The preparation and evaluation of the Euglena adhesive were conducted as follows: First, powdered paramylon ester, the raw material for the Euglena adhesive, was synthesized by adding fatty acids to paramylon using an organic synthesis technique. The powder was processed into a transparent film (0.05-mm-thick film) via heat pressing (Figure 2).

Figure 2. Chemical structure of the raw material for the Euglena adhesive and appearance of the film adhesive

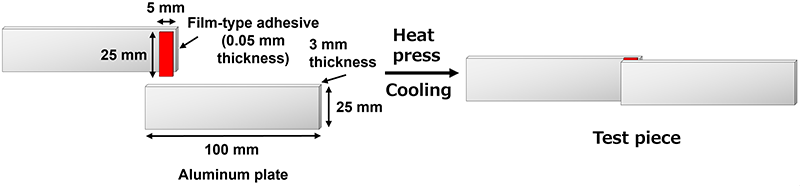

The film was cut into 5 mm×25 mm pieces and placed on the edge of a laser-treated aluminum alloy (A6061) plate (100 mm×25 mm×3 mm), and another similarly treated aluminum plate was placed over the film. The two aluminum sheets were heat-pressed and cooled to create a test specimen with the sheets bonded together (Figure 3).

Figure 3. Preparation of the test specimens

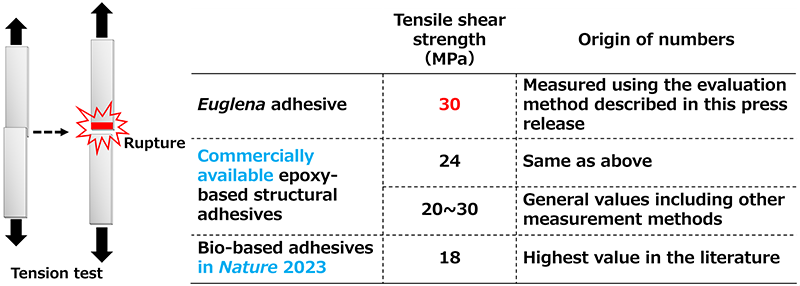

The tensile shear strength was determined based on the force required to rupture the specimen. Figure 4 compares the tensile shear strength values of the Euglena adhesive to those of a typical epoxy-based adhesive for structural materials and a conventional bio-based adhesive with the highest strength. The tensile shear strength of the Euglena adhesive (30 MPa) was comparable to that of typical epoxy adhesives used for structural materials (20–30 MPa) and exceeded the adhesive strength of bio-based adhesives (18 MPa) reported in Nature in September 2023. The force required to rupture the test specimen bonded with the Euglena adhesive was 3750 N, which is equivalent to a weight of approximately 380 kg. Hence, 380 kg was required to rupture the test specimens.

Figure 4. Comparison of the tensile shear strength

Figure 5 shows that a specimen bonded with the Euglena adhesive could be easily disassembled by hand upon reheating. The results of the repeated adhesion evaluations are also presented, showing that the adhesive strength remained consistent even after four cycles of disassembly and reheating. Based on these results, we believe that the Euglena adhesive is the key to disassembling ELV parts.

Figure 5. Disassembly ease and repeatability of use of the Euglena adhesive

Future Plans

The results of this study highlight the potential of Euglena adhesive as a bonding solution for automotive structural materials. Its utilization is expected to facilitate the disassembly of ELVs and the reuse and recycling of their parts, thereby offering a valuable solution to the environmental problems associated with ELVs. To accelerate the social implementation of the Euglena adhesive, we are researching to develop a more efficient synthesis method for the raw material, coupled with a comprehensive evaluation and improvement of the adhesive. Beyond automotive structural materials, we anticipate a wide range of applications for the Euglena adhesive, including in electronic device materials.

Glossary

- Paramylon

- Polysaccharides are glucose-linked molecules that accumulate in the Euglena cells. In environments wherein photosynthesis cannot occur or when nutrient sources such as sugar are depleted, Euglena can sustain its life processes by metabolizing paramylon to generate energy. In other words, paramylon is a crucial source of nutrition for Euglena. [Return to referring word]

- Euglena (freshwater flagellate)

- A type of algae (microalgae) that can be observed under an optical microscope, measuring approximately 50 μm in length. It can swim in water using its flagellum, which is a long hair-like organ, and can multiply using the sugars in the water as a source of nutrients. These algae possess chloroplasts capable of photosynthesis, thereby making them unique organisms with both animal and plant characteristics. [Return to referring word]

- Automotive structural materials

- The demand for aluminum, which contributes to lightweight and highly durable automobiles, is expected to increase in the future. Consequently, the development of adhesives for bonding aluminum has become a globally competitive field. Currently, epoxy adhesives are seen as promising. However, they offer low ease of dismantling. For example, automotive structural materials bonded with epoxy adhesives are generally disassembled in a time-consuming and labor-intensive manner, such as by freezing them in liquid nitrogen and then forcibly removing them using a special tool. [Return to referring word]

- Bio-based adhesives

- Adhesives made from molecules derived from natural products such as plants (biomolecules). Generally, their adhesive strengths are considered to be lower than those of the petroleum-derived adhesives, such as epoxy adhesives. [Return to referring word]

- Fatty acid

- Fatty acids are a type of acid that contains a carboxyl group, which is made up of carbon, hydrogen, and oxygen. They are abundant in nature. [Return to referring word]

- Epoxy adhesives

- The main component of an epoxy adhesive is a resin containing epoxy groups, which are functional groups with a three-membered ring (triangular) structure comprising carbon and oxygen. Cross-linking (bridging) occurs owing to the high reactivity of the epoxy groups, thereby resulting in an interconnected structure of numerous molecules. This gives the adhesive excellent toughness, water resistance, heat resistance, and chemical resistance. Because of their excellent strength and performance, epoxy adhesives are widely used in fields such as automobiles and aircraft. They are available in 1- and 2-component types, thereby enabling adhesion to metals, wood, concrete, and plastic. [Return to referring word]

- Laser-treated

- Laser surface treatment was developed as part of the interface design technology aimed at ensuring the long-term stability of car body adhesion (2021-2024) (NEDO).

"Effect of laser pre-treatment on adhesive joint performance and evaluation of interfacial strain distribution using mechanoluminescence," N. Terasaki, Y. Fujio, Y. Sakata, K. Houjou, K. Shimamoto, H. Akiyama, K. Yase, S. Horiuchi, S. Hartwig, J. Steinberg, C. Gundlach, R. Hirakawa, The Journal of Adhesion, 2024, 1–18. https://doi.org/10.1080/00218464.2024.2313103 [Return to referring word]

- Tensile shear strength

- It is a numerical measure of how effectively bonded materials can withstand lateral forces. It is evaluated using the method outlined in ISO 4587, which specifies the adhesive determination of the tensile lap-shear strength of rigid-to-rigid bonded assemblies, and JIS K 6850, which describes the adhesive determination of the tensile shear bond strength for similar assemblies. Because most industrial products are designed to operate under tensile shear, these measurements are considered the most representative indices of adhesive strength. [Return to referring word]

- Bio-based adhesives (18 MPa) reported in Nature

- Reactive adhesives were synthesized using three types of bioderived substances as starting materials, resulting in a bio-based adhesive with very high adhesive strength.

"Sustainably sourced components to generate high-strength adhesives," C. R. Westerman, B. C. McGill, J. J. Wilker, Nature 2023, 621, 306–311. [Return to referring word]