—Contributing to the development of high-precision optical elements and advanced product quality control—

Researchers) KAWASHIMA Natsumi, Researcher, HIRAI Akiko, Group Leader, KONDO Yohan, Senior Researcher, BITOU Youichi, Deputy Director, Research Institute, Research Institute for Engineering Measurement

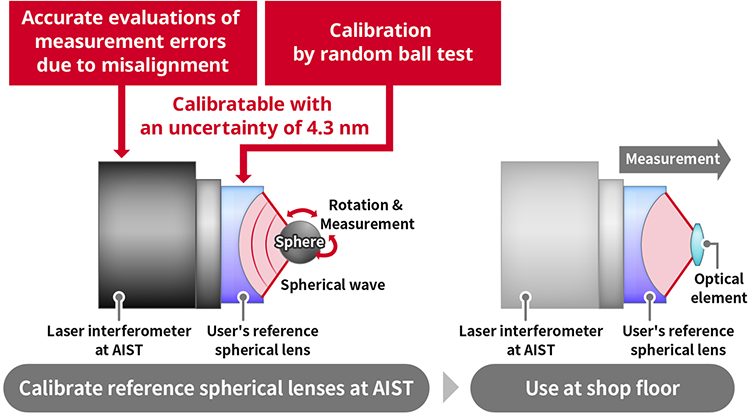

- Developed an efficient and simple system to calibrate the sphericity of reference spherical lens surface profiles, which is indispensable for the development and manufacture of high-precision optical elements, with an uncertainty of 4.3 nm, which is comparable to the conventional system

- Eliminates the need for precise optical system adjustment while maintaining small uncertainties by adoption of a random ball test method and establishment of an uncertainty evaluation method

- Will provide calibration service of surface profile of reference spherical lenses of optical component manufacturers with small uncertainty

Relation between AIST's sphericity calibration system and reference spherical lenses used in production sites

Compact and high-precision lenses are used in cameras mounted on smartphones, head-mounted displays, etc. The manufacturing and measurement technologies to achieve more precise optical elements to obtain high-definition images are constantly improving.

The surface profile of such an optical element determines its performance, such as resolution. In order to meet the required specifications, not only high-precision processing technology is required, but also accurate measurement and evaluation is necessary to ensure that they are fabricated as designed. The profile measuring apparatus used for this purpose needs a reference spherical lens. Although commercially available high-precision profile measuring apparatuses (laser interferometers) have sub-nanometer resolution and several-nanometer-order measurement repeatability, the sphericity calibration accuracy of the reference spherical lens is a bottleneck in the measurement accuracy of laser interferometers. Additionally, in the production site, it is necessary to have a variety of reference spherical lenses with different f-numbers to match the measured sample. The conventional sphericity calibration system at AIST required the use of two reference spherical lenses with the same f-number. Therefore, when calibrating a reference spherical lens with an f-number different from the f-number of AIST’s reference spherical lens, the client had to prepare two identical lenses.

Researchers at AIST have developed a high-precision sphericity calibration system of reference spherical lenses with an uncertainty of 4.3 nm.

High-precision compact lenses are indispensable for cameras used in smartphones, endoscopes, etc. to obtain high-definition images. To achieve high precision in optical elements such as lenses and mirrors, it is necessary to fabricate the absolute profile of the element with the designed profile at the nanometer level.

Therefore, it is necessary to precisely and accurately measure the processed surface profile and evaluate the deviation from the designed profile. The high-precision profile measuring apparatus measures the sample profile by referring to the reference spherical lens with a high sphericity. The sphericity of the reference spherical lens determines the accuracy of the measurement.

In the sphericity calibration system using laser interferometer, we have established a system to easily calibrate reference spherical lenses of any f-number used in the industry by a practical method called the random ball test. We have also established an uncertainty evaluation method based on a detailed analysis of measurement errors caused by misalignment of the optical system. By adopting the random ball test and the uncertainty evaluation method, we have realized a calibration system for user's reference spherical lens of any f-number with a measurement uncertainty of 4.3 nm. Through the calibration system for reference spherical lenses used in industry, we will contribute to the development of high-precision optical elements and the advancement of product quality control.

Journal: Optics and Lasers in Engineering

Title of paper: Novel analysis of alignment error on spherical Fizeau interferometer and uncertainty evaluation of sphericity calibration system based on random ball test

Authors: Natsumi Kawashima, Yohan Kondo, Akiko Hirai, and Youichi Bitou

DOI: https://doi.org/10.1016/j.optlaseng.2024.108646