– Expectations for new maintenance-free thermoelectric modules that do not degrade the electrode interface –

Researchers) GOTO Yosuke, Senior Researcher, LEE Chul-Ho, Prime Senior Researcher, MURATA Masayuki, Senior Researcher, Research Institute for Energy Conservation

- Discovery of a new group of goniopolar materials

- First-principles calculations elucidate the mechanism of the intersection of heat flow and electron (hole) migration

- Expectations for the discovery of new materials with higher performance

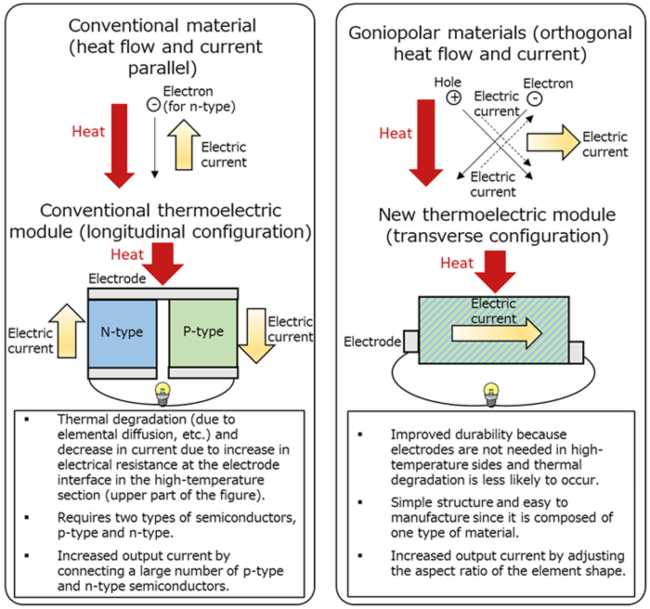

Schematic diagram of conventional (temperature difference and current are parallel) and new type (temperature difference and current are orthogonal) thermoelectric modules

Thermoelectric power generation, which generates electricity using waste heat that had been discarded unused, has the advantage of being a solid-state device with no moving parts, which means that it generates no vibration or noise and is, in principle, maintenance-free. On the other hand, when the device is actually in contact with a high-temperature heat source, chemical reactions and elemental diffusion at the electrode interface degrade its performance, making it a challenge for practical application. To solve this problem, a "transverse" thermoelectric module has been proposed, in which the temperature difference and the power generation are orthogonal to each other. In order to realize this transverse thermoelectric module, the use of goniopolar materials (gonio means rotation or angle in Greek), in which the direction of movement of electrons and holes in a single material differs depending on the crystallographic direction, has been proposed. In addition to the feature that the temperature difference and the power generation are orthogonal, the structure is expected to be simple and easy to manufacture because it is composed of one type of material instead of requiring the assembly of two types of semiconductors, p-type and n-type. In addition, the conversion efficiency is expected to increase by adjusting the aspect ratio (thinner). However, little progress has been made in developing high-performance materials with the extremely unique property of goniopolarity.

Researchers at AIST, in collaboration with Shimane University, have succeeded in developing a unique thermoelectric material (goniopolar material) that can orthogonalize temperature differences and current direction.

Most primary energy is discharged as heat, and to make effective use of this unused heat (waste heat), development of thermoelectric materials that convert heat into electricity is underway worldwide. In recent years, new materials with high performance have been reported one after another, but only Bi2Te3 based materials, which were discovered more than half a century ago and operate near room temperature, have been put to practical use. The lack of practical thermoelectric modules that can operate at temperatures higher than room temperature has hindered progress in power generation using waste heat. In particular, conventional thermoelectric modules have a "longitudinal" configuration in which the heat flow and the power generation direction are the same, which causes elemental diffusion and other reactions at the electrode interface in contact with the high-temperature heat source during power generation, leading to degradation, which poses a durability challenge. The research group fabricated single crystals of Mg3Sb2 and Mg3Bi2 with precisely controlled carrier density and discovered an extremely unique property (goniopolarity) that leads to the realization of "transverse" thermoelectric modules in which the heat flow and power generation direction are orthogonal. The transverse thermoelectric module does not require electrodes at the high-temperature side of the module, which prevents thermal degradation, and is expected to drastically solve the durability issue that has been the bottleneck of conventional thermoelectric modules.

First-principles calculations were performed to elucidate the origin of the goniopolarity, and it was found that the sign of charge carriers differs depending on the crystallographic direction due to the anisotropy of the electronic structure. Since there are many materials with similar characteristics, the application of the method used in this study is expected to lead to the development of thermoelectric modules with higher performance.