– Realization of high-efficiency synthesis by a new reaction that does not produce water –

Researchers) FUKAYA Norihisa, Leader, and PUTRO Wahyu, Researcher, Heteroatom Chemistry Team, and CHOI Jun-Chul, Leader, Catalyst Design Team, Interdisciplinary Research Center for Catalytic Chemistry

- Development of catalyst technology for synthesizing a raw material for polycarbonate and polyurethane from CO2 and a silicon compound

- Longer catalyst life due to a reaction process that does not produce water as a by-product

- Expected to contribute to a carbon recycling society that reuses CO2 as a carbon resource

Synthesis of a raw material for polycarbonate and polyurethane from CO2 and a silicon compound

Technical development for "carbon recycling," in which CO2 is collected and reused as a carbon resource to produce various useful products, is considered important to greatly reduce CO2 emissions associated with the use of fossil fuels. In the "Roadmap for Carbon Recycling Technologies" formulated by the Agency for Natural Resources and Energy on June 7, 2019, "oxygenated compounds (compounds containing oxygen atoms)" as raw materials for urethane and polycarbonate are assumed as examples of use of CO2 in chemical products.

A study of a reaction using CO2 and alcohol as raw materials has been reported as a technology for synthesizing an oxygenated compound used as a raw material for polycarbonate and polyurethane from CO2. However, there are issues with the production efficiency of the target substance and the life of the catalyst used for the reaction, and a technology that can realize lower manufacturing process costs is demanded for practical application.

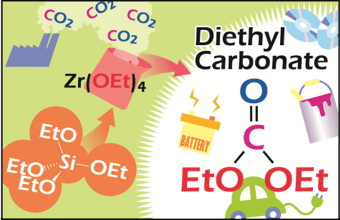

The researchers, in collaboration with Tosoh Corporation, have developed a catalyst technology that efficiently synthesizes diethyl carbonate, which is a raw material for polycarbonate and polyurethane, using CO2 and a silicon compound as raw materials.

A new catalytic reaction was discovered that produces diethyl carbonate using CO2 and a silicon compound (tetraethoxysilane) as raw materials. This reaction does not produce water as a by-product, so the catalyst life was extended and high reaction efficiency was achieved. Practical application of the developed technology is expected to contribute to a carbon recycling society that reuses CO2 as a carbon resource.