– Enables aluminum-containing materials to be utilized in solar cells, which was a challenge for low-cost growth methods –

Researchers) SUGAYA Takeyoshi, Leader, SHOJI Yasushi, Researcher, OSHIMA Ryuji, assigned to the team, and MAKITA Kikuo, Invited Senior Researcher, Multijunction PV Team, Global Zero Emission Research Center

- Development of a reactor that can form high-quality layers of aluminum-containing materials, which was a challenge for growth methods that use inexpensive raw materials

- Demonstration of solar cells with aliminum-containing layers using the developed reactor

- Prospects for the spread of high-efficiency III-V compound solar cells into terrestrial applications

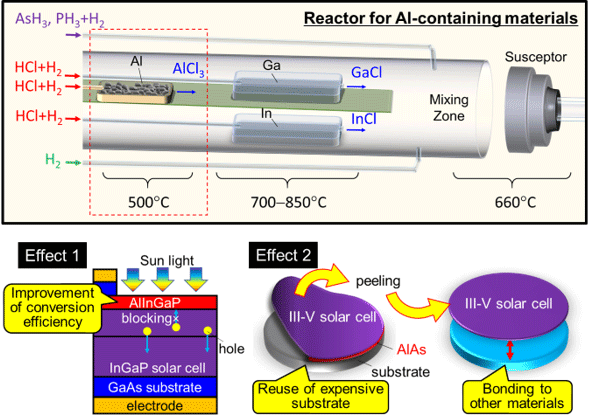

Developed reactor (top) and achieved technologies for III-V compound solar cells using the developed reactor (bottom)

III-V multijunction solar cells, which consist of multiple solar cells with different bandgap, can absorb sunlight over a wide wavelength range leading to high power generation efficiency.

They currently have the highest power generation efficiency among existing solar cells and are used for satellites because of high radiation resistance. However, high manufacturing costs have been a major issue when considering the widespread of application such as electric vehicles. Such high manufacturing costs is mainly due to a slow growth rate for the conventional growth methods in addition to the use of expensive raw materials and parent substrates.

The hydride vapor phase epitaxy (HVPE) method is a key to spread next-generation solar cells into terrestrial applications. The researchers and Taiyo Nippon Sanso Corporation have developed a reactor that enable us to form high-quality layers of aluminum (Al) containing materials in HVPE.

The HVPE is expected to be a low-cost growth method for III-V compound solar cells because of its high-speed growth using inexpensive raw materials compared to conventional methods.

The developed reactor can generate aluminum trichloride (AlCl3) rather than aluminum monochloride (AlCl) by adding the heating zone to react Al raw metals with hydrogen chloride gas at a low temperature of 500 °C. Since AlCl3 does not easily react with a quartz reactor, this development has made it possible to implement high-quality aluminum indium gallium phosphide (AlInGaP) and aluminum arsenide (AlAs) layers on solar cells. The surface recombination of Indium gallium phosphide (InGaP) solar cells was effectively suppressed by the introduction of an AlInGaP passivation layer, resulting in enhancing power generation efficiency. An AlAs layer also enabled us to separate the solar cell layers from the expensive substrates, which can expect to reuse the substrates. In addition, these separated solar cell layers can be mounted on other solar cell devices (silicon, copper indium gallium selenides and so on) by applying AIST's Smart Stacking bonding technology to make high-efficiency, low-cost tandem solar cells. The developed technology will greatly contribute to reducing costs and increasing efficiency of III-V compound solar cells and is expected to be a breakthrough that will make ultra-high efficiency solar cells more accessible.