-Towards application to vibration and pressure sensors in high-temperature environments -

Morito Akiyama (Leader) and Toshihiro Kamohara (Post-Doctoral Research Scientist), the Process Measurement Team, the Measurement Solution Research Center (Director: Kazuo Igarashi) of the National Institute of Advanced Industrial Science and Technology (AIST) (Director: Hiroyuki Yoshikawa) and the Denso Research Laboratories, Denso Corporation (DENSO) (President: Nobuaki Kato) have jointly succeeded in preparing an entirely new composite nitride piezoelectric thin film that possesses high heat resistance and large piezoelectricity.

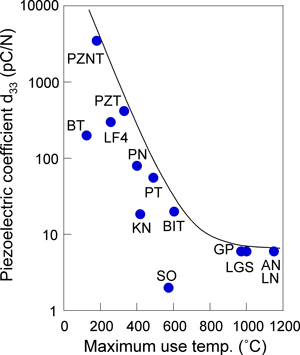

Generally, the piezoelectricity of a substance tends to decrease as heat resistance increases (i.e., as the Curie point increases; Fig. 1). Therefore, it had been considered difficult to prepare a heat-resistant yet strongly piezoelectric material. Given this fact, the team decided to search for a suitable composite nitride, and not general piezoelectric substances of composite oxide, which had only rarely been researched up until now. It was discovered that a composite nitride thin film made from a solid solution of scandium (Sc) in aluminum nitride (AlN) had five times the piezoelectricity (piezoelectric constant d33: 25pC/N) of AlN, which has the highest value among nitrides. In addition, this composite nitride has a crystal structure that does not change even when heated up to 500°C and can therefore be expected to retain its piezoelectricity even at such high temperature. Furthermore, this composite nitride is environment-friendly because it is free of harmful elements such as lead, can be manufactured using existing semiconductor manufacturing processes, and is suitable for mass production; this makes it favorable for use as a new sensor.

Part of the results will be published in a German journal, "Advanced Materials (Wiley-VCH Journals)."

|

Figure 1. Relationship between piezoelectric coefficient d33 and maximum use temperature for piezoelectric ceramics. Most are the Curie temperature. AlN and LGS are known maximum use temperature. AN:AlN. BT:BaTiO3. BIT:Bi4Ti3O12. GP:GaPO4. KN:KNbO3. LF4:(K0.44Na0.52Li0.04)(Nb0.86Ta0.10Sb0.04)3. LGS:La3Ga5SiO14. LN:LiNbO3. PN:PbNb206. PT:PbTiO3. PZNT:0.92Pb(Zn1/3Nd2/3)O3-0.08PbTiO3. PZT:Pb(Zr0.52Ti0.48)O3. SO:SiO2. |

Environmental degradation such as the increase in atmospheric carbon dioxide (CO2) levels is considered the leading cause of global warming, while increase in nitrogen oxides emission is said to cause acid rain; these are growing concerns. In addition, worldwide economical problems related to high crude oil prices are spreading. Thus, advances in the sophistication of internal combustion technology for automobiles, aircraft, gas turbine engines, as well as the need to reduce oil consumption, strongly require the development of highly heat-resistant combustion pressure sensors. Vibration sensors with heat resistance and durability are needed to increase the safety of aging power and chemical plants. However, since no piezoelectric material with high heat-resistance and high piezoelectricity has been developed, combustion pressure sensors and high-temperature vibration sensors with sufficient performance have not been developed.

Generally, the piezoelectricity of substances tends to decrease as heat resistance increases (i.e., as the Curie point increases; refer to Fig. 1). Therefore, it had been considered difficult to fabricate a highly heat-resistant yet highly piezoelectric material. However, the need for high-temperature piezoelectric sensors has been increasing rapidly the world over, and this has lead to a strong anticipation for the development of a piezoelectric substance with both heat resistance and piezoelectricity.

Traditionally, research on piezoelectric substances has been focused on composite oxides. However, oxides free of harmful elements such as lead do not achieve enough performance at high temperatures. The Process Measurement Team, the Measurement Solution Research Center of AIST, and a group of DENSO investigated nitrides that have not been well researched in the field of piezoelectric materials. Composite nitrides such as composite gallium nitride (GaN) have been the focus of active research in the field of LED and semiconductor lasers; however, only a few kinds of piezoelectric nitrides have been reported up until now, and few examples exist of studies related to the piezoelectricity of composite nitrides.

To find a piezoelectric material with high heat-resistance and large piezoelectricity, a search was conducted for composite nitrides which are rarely studied as piezoelectric materials, and not for general composite oxide piezoelectric materials. Piezoelectricity was improved by preparing thin films of solid-solution of various elements and aluminum nitride (AlN), which has low piezoelectricity and high heat-resistance. The composite nitride was prepared by utilizing the binary simultaneous reactive sputtering method. Aluminum and the substituting element were simultaneously sputtered and reacted with nitrogen.

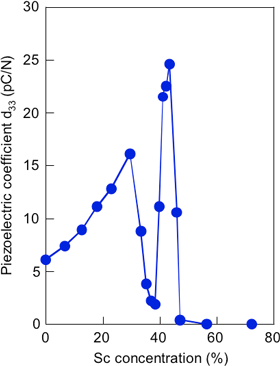

Evaluation and analysis of the piezoelectricity of the prepared membrane revealed, as shown in Fig. 2, that the piezoelectricity varies with the amount of scandium (Sc) in the solid solution, that the piezoelectricity is fivefold (piezoelectric constant d33: 25pC/N) that of aluminum nitride (AlN) when the Sc in the solid solution is 43%, and that this value is the highest value for all known nitrides. A piezoelectric materials generally maintains its piezoelectricity up to just below the Curie point, and then loses its piezoelectricity because of the rapid crystal structure changes at the Curie point. This composite nitride thin film has a crystal structure that does not change even when heated up to 500°C and can therefore be expected to remain piezoelectric at high temperature.

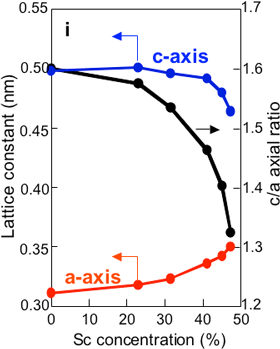

Measurement of the crystal structure of this composite nitride (Fig. 3) revealed that as the Sc concentration increases, the a axis of the unit cell grows in length and the c axis of it becomes much shorter. Taking into account other measurements such as that of elastic modulus, it is considered that the piezoelectricity of this composite nitride was improved due to the following two factors: One is that the localization of electrons increases when aluminum is substituted by Sc, which has low electronegativity, and the other is that as the amount of Sc increases, the elastic modulus decreases, making it more deformable.

This composite nitride material is not only has superior piezoelectricity and heat resistance, but is also environment-friendly because it is free of harmful elements such as lead. Since it can be fabricated as a film, it can be manufactured using existing semiconductor manufacturing processes and is suitable for mass production. Thus this film is favorable for use as devices including new sensors and actuators.

In the future, it is expected to be applied to control systems and safety management systems for automobiles, aircraft, power generators, chemical plants, etc.

Figure 2. Dependence of piezoelectric coefficient d33 of ScxAl1-xN alloys on Sc concentration. |

|

Figure 3. Dependence of lattice constants of ScxAl1-xN alloys on Sc concentration. (The blue, red and green represent c-axis length, a-axis length, c/a axial ratio, respectively.) The a and c axis length is calculated by using the images of electron beam diffractions. |

The mechanism of high piezoelectricity of this composite nitride will be clarified and its threshold temperature for use will be identified. Since it is a piezoelectric nitride, use under high pressure is expected, and its pressure durability characteristics will be investigated. The goal will be the development of a new vibration and pressure sensors for harsh environments such as high-temperature and high-pressure.