Shigeru Niki (Leader, also Deputy Director of RCPV) and Shogo Ishizuka (Research Scientist), the Thin Film Compound Semiconductor Team, the Research Center for Photovoltaics (RCPV) (Director: Michio Kondo) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa), with cooperation of Teijin Limited (Teijin), have developed a technique for dramatically improving the energy conversion efficiency of flexible photovoltaic cells that use CIGS, a non-silicon material. Using this technique, high-performance photovoltaic cells with a variety of flexible substrates such as ceramics, metal foils, and polymers are fabricated.

The thickness of the photoelectric conversion layer in solar cells that use CIGS, a semiconducting material made of copper (Cu), indium (In), gallium (Ga), and selenium (Se), can be reduced to the order of several micrometers. Owing to this feature, ligh-tweight and flexible photovoltaic cells that can be installed on a curved surface and portable photovoltaic cells are expected to be realized. It has been difficult to develop high-performance flexible CIGS photovoltaic cells, so far. By the development of a new controlled alkaline addition technique and a new polymer substrate handling technology, the energy conversion efficiency of the flexible CIGS photovoltaic cells is dramatically improved.

The results of this research will be announced at the 4th Annual Symposium of Research Center for Photovoltaics, AIST to be held at the National Museum of Emerging Science and Innovation on July 28 and 29, 2008, and at the 23rd European Photovoltaic Solar Energy Conference and Exhibition to be held in Valencia, Spain onSeptember 1-5, 2008.

|

|

|

|

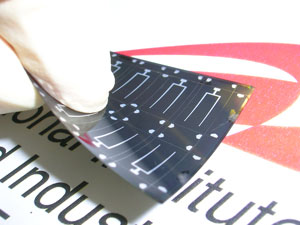

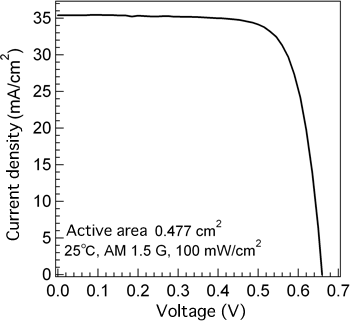

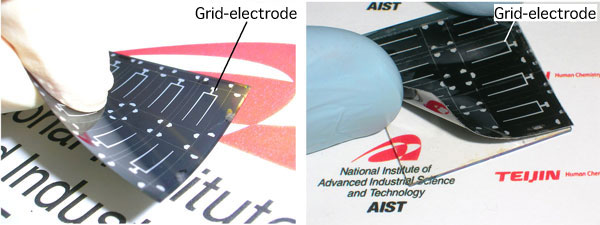

Flexible CIGS solar cells fabricated using a ceramics sheet substrate (left) and a polymer film substrate (right).

|

Because of growing concerns about environmental problems and increasing crude oil prices, there is an increased interest in power generation using renewable energy such as photovoltaics and other new energy resources.

The CIGS photovoltaic cell has many excellent features such as 1) high energy conversion efficiency, 2) long-term reliability with no aged deterioration, 3) solid black color that allows a wide range of designs, and 4) high resistance to radiation that enables its use even in cosmic space. Its short energy payback time, which is approximately one year, is half that of the polysilicon solar cell, and low-cost manufacturing of the cell can be expected. CIGS photovoltaic cells are already in practical use; commercial production and sale of solar panel modules have been started in 2007 by domestic manufacturers.

Another important feature of the CIGS photovoltaic cell is that the thickness of its photo-absorber layer can be reduced to the order of several micrometers. Due to the thinness of the layer, the amount of raw material used can be reduced, and the flexible cell can be fabricated. Realization of a high-performance flexible photovoltaic cell, which can be installed on a curved surface or made into light-weight and portable components, would result in widespread use and popularization of photovoltaic cells.

Based on the CIGS absorber layer growth technique using multi-source evaporation method, AIST is making significant efforts toward the development of 1) in situ observation and control techniques for film growth, 2) a process for manufacturing photovoltaic cell suitable for a wide band gap CIGS , 3) a method for controlling crystal defects in the CIGS absorber layer, and 4) a method for a resource-saving film growth using a radical selenium source. The RCPV, AIST is conducting basic studies such as control and evaluation of the properties of CIGS as well as applied research such as the development of an integrated module and flexible photovoltaic cells with enhanced performance.

This research was supported by the "Research and Development of CIGS Photovoltaic Cell Performance Improvement" scheme (FY2006-2009) of the Research and Development of Future Photovoltaic System Technologies project sponsored by the New Energy and Industrial Technology Development Organization (NEDO).

One of the technical issues remaining to be solved for improvement of the performance of flexible CIGS photovoltaic cells is control of the alkali doping level in the CIGS absorber layer. Alkali metals such as sodium (Na) are known to be used in CIGS photovoltaic cells as indispensable impurities (dopants) for enhancement of hole carrier concentration and open circuit voltage. For improving the performance of flexible CIGS photovoltaic cells, various alkali addition methods, in which alkali compounds such as sodium selenide (Na2Se) and sodium fluoride (NaF) are used as alkali precursors and deposited before, after, or during CIGS layer growth, have been examined. However, because many of these alkali compounds are very difficult to handle due to their unstable properties such as deliquescence, performance improvement of the photovoltaic cells with satisfactory reproducibility has not been achieved.

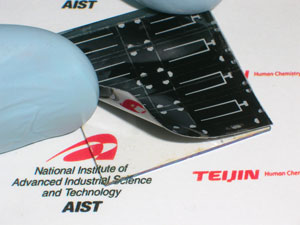

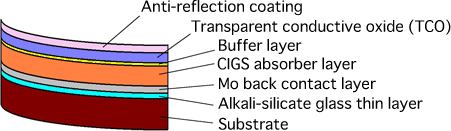

At AIST, we used alkali-silicate glass thin layers (ASTL) as alkali source materials, which are stable alkali compounds, deposited on the substrate prior to the molybdenum (Mo) back contact layer deposition, as shown in Fig. 1, and developed a technique for controlling the quantity of alkali incorporated into the CIGS absorber layer through the Mo back contact layer by controlling the deposition conditions of ASTL (the "ASTL method"). Using this technique, we can perform alkali addition with ease as well as high reproducibility, and thus, can bring about a significant improvement in the energy conversion efficiency of CIGS photovoltaic cells. We fabricated a small-area flexible CIGS photovoltaic cell with a ceramics substrate with smooth surface using the ASTL method and achieved an active-area efficiency of 17.7%. By using a substrate made of titanium foil, which has a slightly rough surface, we could achieve a conversion efficiency of 17.4%. 17.7% energy conversion efficiency of the flexible CGIS photovoltaic cell (see Fig. 2) is the highest value for flexible CIGS cells reported to date.

|

|

Figure 1 Schematic illustration of a high-efficiency flexible CIGS solar cell developed in the present work. As alkali source materials, alkali-silicate thin layers (ASTL) are deposited on flexible substrates prior to sputtering of the Mo back contact layer.

Al Grid electrodes as shown in Fig. 3 were formed by evaporation on the TCO layer before anti-reflection coating.

|

|

Photovoltaic parameters

Efficiency : 17.7%

Open circuit voltage : 0.660 V

Short circuit current density : 35.4 mA/cm2

Fill factor : 0.757

|

|

Figure 2 Current-voltage curve of the flexible CIGS solar cell fabricated on a ceramics sheet using the ASTL method. The CIGS absorber layer was grown at the substrate temperature of 550°C.

|

|

|

Figure 3 Flexible CIGS solar cells

|

|

(left) Ceramics substrate

|

(right) Polymer substrate

|

Polymeric materials, which are light-weight, insulating, and inexpensive, are gaining attention as suitable materials for flexible substrates. The polymeric materials need to be processed at lower than approximately 450 °C, however, a temperature of higher than 500 °C is necessary to form a CIGS light-absorbing layer having a high energy conversion efficiency. Furthermore, it is difficult to handle polymer-made substrates, thereby making it almost impossible to realize high energy conversion efficiency in a CIGS photovoltaic cell fabricated using a polymer substrate. Very few researchers have reported an energy conversion efficiency of more than 12%.

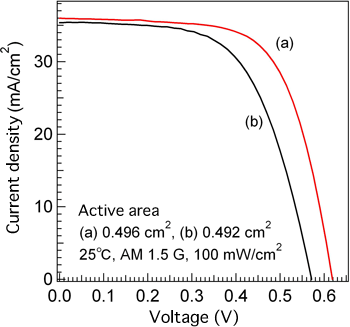

Recently, Teijin has developed a polymer film that is spin-coated on a glass substrate. After a CIGS photovoltaic cell has been formed on this polymer film, the film can be easily peeled off from the glass substrate, as shown in Fig. 3 (right). The flexible CIGS photovoltaic cell with this polymer substrate fabricated using the ASTL method is not only easy to handle but also has improved open voltage and fill factor due to the alkali-addition effect, with an active-area efficiency of 14.7% (Fig. 4). The CIGS absorber layer of the cell was formed at 400 °C. This energy conversion efficiency is the highest value reported for CIGS photovoltaic cells fabricated on polymer substrates. The use of this polymer substrate enables fabrication of flexible CIGS solar cells using a common apparatus designed for panel module fabrication and no specialized equipment such as roll-to-roll machines are required.

|

(a) — with ASTL

Efficiency : 14.7%

Open circuit voltage : 0.619 V

Short circuit current density : 36.0 mA/cm2

Fill factor : 0.658

(b) — without ASTL

Efficiency : 12.2%

Open circuit voltage : 0.571 V

Short circuit current density : 35.4 mA/cm2

Fill factor : 0.604

|

|

Figure 4 Current-voltage curves from flexible CIGS solar cells fabricated on polymer substrates. CIGS absorber layers were grown at the substrate temperature of 400°C.

|

We intend to apply the method for enhancing the energy conversion efficiency of small-area flexible CIGS photovoltaic cells to submodules of practical dimensions, and continue research and development endeavors to address technical issues such as integration process for scale-up and improvement of the yield rate.