- Accelerating the mass production of highly-pure single-walled carbon nanotubes -

Kenji Hata (Leader) and Tatsuki Hiraoka (Post-Doctoral Research Scientist) of the Nano-Carbon Materials Team, the Research Center for Advanced Carbon Materials (Director: Sumio Iijima) of the National Institute of Advanced Industrial Science and Technology (President: Hiroyuki Yoshikawa) (hereinafter referred to as AIST) and Zeon Corporation (President: Naozumi Furukawa) have jointly developed a technology to synthesize a large amount of single-walled carbon nanotubes directly on large area metal substrates for the first time. We used “super-growth” CVD method, which is one of the methods of synthesizing single-walled carbon nanotubes.

The standard “super-growth” method uses an expensive silicon substrate to synthesize single-walled carbon nanotubes, but this research succeeded in synthesis on inexpensive nickel alloy substrates. At the same time, the research team designed and built a trial synthesis furnace that can utilize the newly developed technology jointly with Zeon Corp., and we successfully synthesized single-walled carbon nanotubes with a uniform structure spanning an A4 size foil substrate. This large area synthesis is a 100 times jump from conventional levels, and production was scaled in units of grams. Single-walled carbon nanotubes synthesized by this newly-developed technology grow upward vertically from the metal foil, and it takes only 10 minutes to form a structure of 1 mm height. The single-walled carbon nanotubes exhibit excellent properties, including the world’s highest level of purity and greatest specific surface and length, similar to those synthesized on silicon substrates, and they are considered to be promising for various applications such as super-capacitors and actuators. The newly developed technology reduces the substrate cost to one-hundredth of the existing cost. As the key technology for developing a large-area and continuous production technology for carbon nanotubes, it is paving the way for industrial mass production of single-walled carbon nanotubes. Some of the results of this research have been published in the Journal of the American Chemical Society (Vol. 128, p. 13338, 2006), an American journal in the chemistry field.

Figure 1: Single-walled carbon nanotubes structure synthesized on the A4 size metal foil

|

|

Figure 2: Vertically aligned single-walled carbon nanotubes structure on the Inconel® (Nickel alloy)

|

The single-walled carbon nanotube is a carbon material with new properties, including high levels of electrical conductivity, flexibility, anisotropy, and low-dimensionality. It is attracting wide attention as a material for next-generation nanodevices, and has high levels of expectation as a fundamental building block as the core to nanotechnology of the 21st century. Although research and development for its applications is undergoing fierce competition worldwide, there is no established industrial application because the technology to synthesize single-walled carbon nanotubes has not yet matured. Development of a synthesis method that will endow the single-walled carbon nanotube with high alignment, high density, high specific surface, good length, and high purity is required if we are to take full advantage of its highly promising possibilities. Furthermore, besides increasing growth efficiency, the development of the technology to mass-produce nanotubes continuously on large area inexpensive substrates is vital for the feasible use of single-walled carbon nanotube as an industrial material.

AIST has been actively developing an inexpensive, synthetic mass-production technology for single-walled carbon nanotubes based on the super growth technology that was reported in 2004 as a way of realizing the world’s highest large-area growth efficiency. Kenji Hata and Tatsuki Hiraoka have been trying to apply the method to synthesize super-growth single-walled carbon nanotubes on less expensive metal substrates in place of on conventional expensive silicon substrate. At the same time, we are developing mass production technology that would allow for large-area and continuous production jointly with Zeon Corp.

This research has been conducted with the support of the nanotechnology program “Carbon Nanotube Capacitor Development Project” (2006–2010), sponsored by the New Energy and Industrial Technology Development Organization (NEDO).

We examined the technology necessary to mass-produce high quality carbon nanotubes on substrates made from relatively inexpensive materials, coated with catalyst material, instead of using the currently used and expensive silicon wafers. As a chemical vapor deposition (CVD) technology, we used the super-growth technology developed by AIST’s Nano-Carbon Materials Team. This is a method of synthesizing single-walled carbon nanotubes on substrates with the world’s highest growth efficiency.

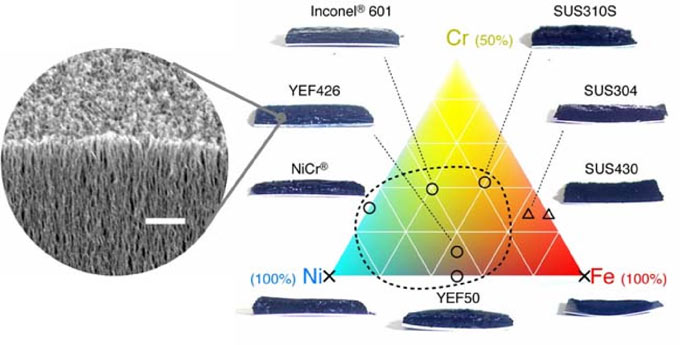

This method requires a substrate that does not disrupt the synthesis of carbon nanotubes. In addition, it must also be able to endure the growth ambient, such as a hydrogen-reduction atmosphere, moisture addition, and an oxidative atmosphere at a temperature close to 800 oC. Through our experiments, we found that a specific nickel alloy satisfied these requirements. In particular, we confirmed that we could get the targeted aligned structure if we used nickel alloy plate or a nickel alloy ribbon.

There is no difference in quality, yield, or selectivity between the single-walled carbon nanotubes grown on this nickel alloy and those grown on silicon substrate. That is, it has become possible to synthesize large amounts of single-walled carbon nanotubes on nickel alloy substrate that is far less expensive than silicon substrates and does not impose any size restrictions.

Jointly with Zeon Corp., we designed and built a prototype large-area super-growth furnace to which the newly-developed technology could be applied. We succeeded in synthesizing uniform single-walled carbon nanotube structures on an A4 size metal plate. The product has the world’s highest level of purity (greater than 99.9% carbon purity) and the world’s highest specific surface (higher than 1000 m2/g for unopened nanotubes), greatest length and alignment. It is very useful for various applications, including super-capacitors and actuators.

|

|

Figure 3: Synthesis of single-walled carbon nanotubes structure fabricated on the various mixed alloy substrates (Ni-Fe-Cr); magnified view shows vertically aligned nanotubes in the structure

|

By using this newly developed super-growth technology for carbon nanotube synthesis on metal substrates as a core technology, we making further efforts to reduce the production cost of single-walled carbon nanotubes by several one-hundredths by further scale-up, enhancing the continuous growth process, and increasing efficiency. The results of this research will make it possible to drastically increase the production unit from several milligrams of the existing small batch on silicon substrate to grams, accelerating the development of applications in capacitors, etc. Under the NEDO-sponsored “Carbon Nanotube Capacitor Development Project,” we want to realize industrial mass production of single-walled carbon nanotubes characterized by alignment, good length, high purity, and high specific surface.

The single-walled carbon nanotube synthesized by this method has larger capacitance per specific surface than activated carbon and has the potential to be used as a material in capacitors with high power and energy density. We are trying to develop a two-layer electrocapacitor that satisfies the requirements of high output, high energy density, and long life by making the best use of these properties.

|

|

Figure 4: Single-walled carbon nanotubes synthesis furnace for large-area super growth

|