Update(MM/DD/YYYY):06/18/2007

Successful 65% Reduction in the Energy Consumption of a Circulating Pump by Using a Surfactant

- Verification of the energy-saving effect by using a hot-water circulating pump in the Sapporo City Hall -

Points

-

Conducted an experimental study on reducing flow resistance by injection of a surfactant into circulating heating water

-

Succeeded in reducing by 65% the energy consumption of a circulating pump in the Sapporo City Hall

-

Contributed to reducing carbon dioxide emissions through energy saving

Summary

Hiromi Takeuchi (Deputy Director) and collaborators of the Energy Technology Research Institute (Director: Yoshiro Owadano) of the National Institute of Advanced Industrial Science and Technology (President: Hiroyuki Yoshikawa) (hereinafter referred to as AIST) in collaboration with City of Sapporo (Mayor: Fumio Ueda), Professor Yasuo Kawaguchi of the Department of Mechanical Engineering, the Faculty of Science and Technology, Tokyo University of Science (President: Shin Takeuchi), the Shunan Regional Industry Promotion Center (President: Kazuto Kawamura), and the Fujiwara Environmental Science Institute Ltd. (President: Yozo Fujiwara) have succeeded in reducing by 65% the energy consumption of a circulating pump in the heating system of the Sapporo City Hall: this building has nineteen floors and two basement floors. This reduction in energy consumption was achieved by reducing the flow resistance of the circulating heating water with injecting a surfactant into it.

The system that we examined in the study was a hot-water circulating system that includes a pump with a 37-kW rated output, about 32 tons of water and a water tank. It should be possible to save 58,000 kWh of electricity and to reduce expenditure by ¥630,000 annually, assuming that the system operates for 10 hours per day, 240 days per year at a power cost of ¥11/kWh. In addition, 32 tons/year of carbon dioxide emissions can be eliminated, taking the emission factor for carbon dioxide as 0.555 kg/kWh.

Fig.1 Sapporo City Hall where the actual proof test is performing.

|

|

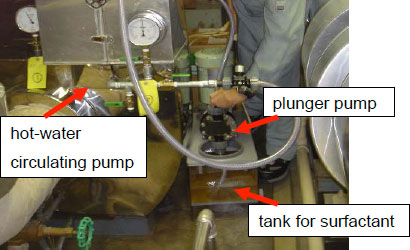

Fig.2 Arrangement of a hot-water circulating pump and a plunger one.

|

|

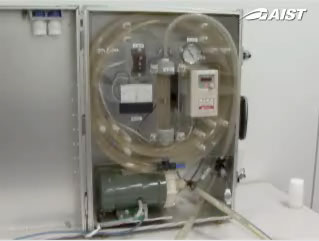

Demonstration of an energy-saving effect using a surfactant.

An energy-saving effect to water circulation is demonstrated using a model apparatus.

By injection of a surfactant, drag reduction is occurred and volume flow rate is increased.

Using an inverter, electric power is reduced to give the same flow volume as before injecting a surfactant. Thus, the energy-saving is achieved.

|

Social Background of Research

The reduction of carbon dioxide emissions is being considered worldwide as a possible means of mitigating global warming. Energy-saving technology can make a major contribution to reducing carbon dioxide emissions. Recently, reducing the motive energy required for delivery of water to air-conditioners inside buildings has attracted attention as a measure for projects such as the Energy Saving Company (ESCO) project, which provides energy-saving services to customers and receives part of collected energy from them as a reward, and the Building Energy Management System (BEMS) project, which promotes energy saving while maintaining comfort inside buildings.

The technology for reducing flow resistance by injecting a surfactant has been studied and used for area-wide air conditioning system, mainly in Europe, but it is not yet widely used for air-conditioners and area-wide air conditioning in Japan, despite research activities in laboratories and universities. This is because it is difficult to estimate the energy-saving effect for air-conditioning systems with complicated piping systems and because maintenance of system varies with the equipment.

For example, the technology has never been applied in snowy cold regions where it is necessary to prevent outdoor equipment from being frozen in winter when outdoor air temperatures are below zero. In addition, needs to be clarified whether it is possible to maintain a certain level of efficiency under conditions where the annual heating period is long and cooling period is short. It is therefore vital to accumulate data and make them public through experimental studies in order to spread the use of this technology.

History of Research

AIST has been conducting researches on various elements of energy-saving technology, and believes that experimental study is a useful measure for “full research” to develop technologies that are actually useful in society. As a municipality, City of Sapporo has been working on energy saving and has been engaged in various activities to keep its citizens informed of the results.

As part of these activities, in December 2004 AIST and City of Sapporo concluded a master agreement on research cooperation for the purpose of effective utilization of energy. On the basis of the agreement, the two parties agreed to cooperate on conducting an experimental study inside the premises of facilities and sites belonging to City of Sapporo, and to promote energy-saving technologies to the citizens of City of Sapporo by presenting relevant data.

Details of Research

We can reduce the friction between a fluid (water including surfactant) and the inner walls of a pipe in which it is flowing by injecting a surfactant into the fluid and making laminar flow. If the fluid is water serving as the heat-transfer medium in an air-conditioning system, we can reduce the energy consumed by the pump that supplies water (both cold and hot) to the air-conditioning unit of each room, thereby saving energy. Injection of a surfactant increases the flow volume of the circulating water, but we can control the flow by reducing the speed of the pump to achieve the rated volume. The speed of the pump can be controlled by using an inverter to reduce the frequency of the electricity supplied to it. The decrease in motive energy supplied to the pump represents a saving in the consumption of electric power.

Before conducting the experimental study, we studied the diameters of the pipes, the flow rate, the water temperature, and the water quality (presence of corrosion inhibitors) as factors that affect the efficiency of the surfactant. As a result of these preliminary studies, we selected LSP-01A (made by LSP Cooperative Society) as the surfactant and set its concentration at about 0.5%. In the experimental study conducted in the city hall, we were able to maintain the rated flow volume at an alternating current frequency of 35 Hz, representing a reduction in electricity consumption of 65% compared with normal operation at a frequency of 50 Hz. (The power consumption is proportional to the cube of the frequency.)

We operated the heating system under these conditions between late February and mid May, and we collected data mainly on the stability of the system and its heating performance. We found no problems.

Future Schedule

As the system uses almost the same circulating pipes for cooling and for heating, we plan to verify during the summer of 2007 that the surfactant used for heating is also effective in cooling. We will estimate the initial costs and running costs in a year-round experimental study. We also plan to examine if use of the surfactant complicates the maintenance of the system.

We expect that this research will not end with the experimental study inside the specific facility, and that the technology that we developed will spread as an effective energy-saving measure for other buildings. We are keen that the technology will be applied to equipment in newly built buildings in the near future.