Update(MM/DD/YYYY):06/04/2007

Successful Development of a Small, High-Performance Micro Fuel Cell Bundle

- Realizes more than two watts of output power in a unit size of a sugar cube (one cubic centimeter) below 600 ℃ -

Points

-

Successful development of a small high power solid oxide fuel cell (SOFC) cubic bundle integrated very fine ceramic tubes in a volume of a sugar cube.

-

The SOFC bundle generates the world’s highest output power density (two watts per cubic centimeter) at an operating temperature of below 600°C, previously considered not possible for SOFCs that are normally operated at high temperatures.

-

Easy to fabricate micro fuel cell stacks, which opens the possibility of developing small SOFC systems with output power ranging from several tens of watts (several tens of cubic centimeters) to several kilowatts (several thousand cubic centimeters)

Summary

Toshio Suzuki (Research Scientist) of the Functional Assembly Technology Group (Group Leader: Masanobu Awano) of the Advanced Manufacturing Research Institute (Director: Hideto Mitome) of the National Institute of Advanced Industrial Science and Technology (President: Hiroyuki Yoshikawa) (hereinafter referred to as AIST) and Yoshihiro Funabashi of the Fine Ceramics Research Association (FCRA) and NGK Spark Plug Co., Ltd. (NGK; President: Norio Kato), have successfully developed a small solid-oxide fuel cell (SOFC) bundle with the size of a sugar cube.

Toho Gas Co., Ltd. (Toho Gas), which is examining small SOFC cubes for cogeneration purpose, evaluated the performance of the newly developed small SOFC bundle and confirmed that it can produce a high output power, even at operating temperatures of below 600°C.

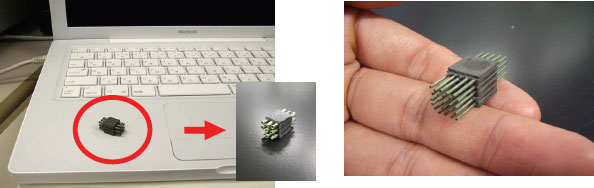

The applications of SOFCs have previously been limited by their high operating temperatures, typically 800–1000 °C, so realization of high output power SOFC modules that operate at lower temperatures have long been expected. AIST, FCRA, and NGK have developed a small, highly integrated, cubic micro SOFC bundle about the size of a sugar cube (Photo 1). Toho Gas examined its electrochemical performance and found that it has the world’s highest power density per volume, of more than two watts per cubic centimeter at below 600 °C.

This achievement should open the way to commercialize practical micro SOFC systems for auxiliary power supplies for vehicles, small cogeneration systems, and portable power units. These research results were presented at the International Ceramic Exhibition on 4th–6th of April 2007 at Tokyo Big Sight.

|

|

Photo 1

|

Social Background of Research

Fuel cells are helpful in reducing emissions of CO2, one of the causes of global warming. For this reason, various approaches to the development of fuel cells are being examined. Of the currently developed fuel cells, SOFCs are the most efficient fuel cells using ceramic technology which is a specialty of Japanese industry. Because typical SOFCs are operated at higher temperatures than do other fuel cells, it can utilize heat exhausts for fuel reformation and hot-water storage to improve the efficiency as a whole. At the same time, SOFCs are durable because they can be made entirely of ceramics. To date, however, because SOFCs have to be operated at high temperatures of between 800 and 1000 °C, they have only been applied in power-generation infrastructure operations with a low thermal cycle and few load changes. Therefore, there has long been a desire to develop an SOFC that could be used in distributed household power systems, to power mobile electronic devices, or as an auxiliary power source for vehicles: such applications would require rapid operation and the ability to be operated at below 650°C.

History of Research

On the basis of the above social background, AIST, FCRA, NGK, and Toho Gas have been trying to develop an SOFC suitable for practical applications that is capable of rapid operation at below 650 °C. This research is a part of the “Advanced Ceramic Reactor” project (2005–2009) of the New Energy and Industrial Technology Development Organization (NEDO). AIST, so far, has successfully developed high-performance tubular micro SOFCs with diameters of millimeters to sub-millimeters.

For practical applications, it is necessary to integrate tubular micro SOFCs to form stacked modules. For this purpose, a structure that can combine a high porosity (to provide an adequate air supply) with a low electrical resistance (to permit current collection) was needed to be developed. It was difficult to build such structures because the electrical resistance of the materials tends to increase if they are perforated to increase their porosity.

AIST, FCRA, and NGK examined ceramic manufacturing technologies such as microstructure controlling technology and cell assemble technology using commercially available ceramic materials, and they developed new methods of integration and manufacturing integrated SOFC bundles.

These efforts were made to develop such high performance SOFC bundles as a part of NEDO’s “Advanced Ceramic Reactor” project.

Details of Research

The SOFC bundle uses lanthanum cobalt as the air electrode material that forms part of the SOFC bundle. This made it possible to establish the technology for producing a small cubic SOFC bundle with a power output of two watts or more per cubic centimeter at below 600 °C. This technology is suitable for mass production, because it relies on basic ceramics-forming technology.

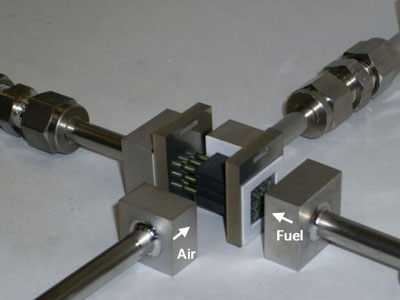

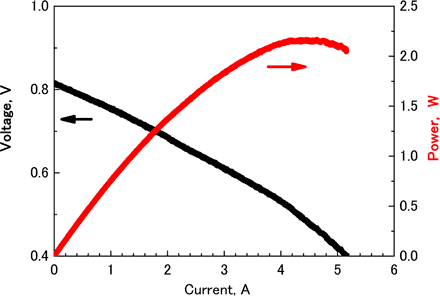

The actual micro SOFC cube bundle is an integrated structure that has a volume of one cubic centimeter and tubular cells with a diameter of 0.8-2.0 mm. Toho Gas examined the performance of the SOFC bundles by flowing hydrogen into micro tubular SOFCs with 2 mm in diameter, operating at 550 °C. The tests confirmed that the SOFC cube bundle generated more than two watts of power (Photo 2). As shown in Figure 2, the test data show that a volume of one cubic centimeter can generate more than two watts of power for a current of 4.5 amperes at the operating temperature of 550 °C.

The tests confirmed that the SOFC bundle produces the highest volumetric power density of any known fuel cell and does so at a current of 4.5 ampere and an operating temperature of below 600 °C. At the same time, the bundle is the world’s smallest fully-fledged micro tube SOFC cube with passages for fuel and air.

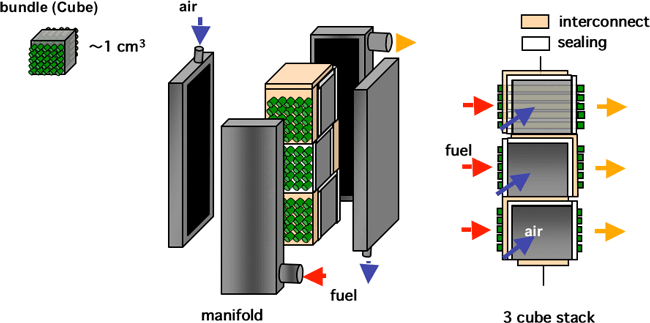

The newly-developed micro SOFC opens the prospect of stacking micro SOFCs to produce stacks and modules ranging in size from small mobile electric power units of several tens of watts with volumes of several tens of cubic centimeters to auxiliary power units for vehicles or household power units with outputs of several kilowatts and volumes of several thousand cubic centimeters. SOFCs are expected to be applied as distributed power units for household use, as power units for mobile electronics devices, and as auxiliary power sources for vehicles.

|

|

Photo 2

|

|

|

Figure 1

|

Future Schedule

While continuing our research to improve the performance of the cube, we will establish the fundamental technology to build stacks through integration of the cube and we will develop high-precision technology for the interface construction for supplying fuel gas to each tube and collecting the current. In the long run, we hope to develop the technology for producing small but highly efficient SOFC stack modules that are capable of rapid operation. (See Figure 2)

|

|

Figure 2

|