Update(MM/DD/YYYY):02/15/2005

Remote Calibration of Length Standard by Using Optical Fiber Network

- Comparison of Block Gauges Separated by 47 kilometers -

Key Points

-

For calibrating a length standard such as a block gauge, it has been necessary to send the standard to a standard research institute or a calibration organization, involving a risk of loss or damage in the course of transportation, and a demerit of taking a long time.

-

A remote calibration of a block gauge has been successfully carried out with an error 60 nm or so, by using a tandem type low coherence interferometer, through an optical fiber communication network between two virtual relay stations, Tsuchiura-city, Ibaraki and Kashiwa-city, Chiba, spanning around 47 km.

-

The practical use of the present remote calibration technology will make it possible for everyone to acquire a traceable supply for a national standard in real time, without taking consideration of distance.

-

Broad spread of length standard will be implemented through the optical fiber communication network to small and medium enterprises, research laboratories and other public users.

Synopsis

Dr. Hirokazu Matsumoto, Deputy Director of the National Metrology Institute of Japan (NMIJ) of the National Institute of Advanced Industrial Science and Technology (AIST), an independent administrative institution, and they have succeeded in transferring precision length through an existing optical fiber communication network about 47 km long between two virtual relay stations, placed at Tsuchiura-city, Ibaraki and Kashiwa-city, Chiba, by using a calibration method based on tandem type low coherence interferometer developed by the NMIJ-AIST, demonstrating the feasibility of remote calibration for length standard such as block gauge.

Earlier, for calibrating a length standard it has been necessary to send a standard itself to a standard research institute or a calibration organization (to be designated as “standard laboratory” hereinafter (so-called take-in calibration) involving a risk of loss or damage in the course of transportation or a demerit of taking a long time.

In order to solve these problems, the NMIJ-AIST has been engaged in a remote standard supply project based on a data communication network, named “e-trace”, so that everyone could get access to national standard, anytime and anywhere. The R&D work on the remote calibration of length standard using an optical fiber system has been carried out as a part of this project. Earlier, the NMIJ-AIST has succeeded in remote precision length measurement of a block gauge through a 10 m long single mode optical fiber by using an original technique based on the “tandem type low coherence interferometer” developed by the NMIJ-AIST, validating in principle the feasibility of remote calibration of length standard (AIST Press Release on March 19, 2003).

For the purpose of demonstrating the practical effectiveness of remote calibration for length standard, a verifying experiment was carried out by use of technology based on tandem type low coherence interferometer between two virtual relay stations located at Tsuchiura-city, Ibaraki and Kashiwa-city, Chiba linked by an existing optical fiber communication network of about 47 km length. Assuming that Tsuchiura-city Station is a standard laboratory, and Kashiwa-city an authorized supplier (or user), remote calibration was done for a length standard (block gauge). In this experiment, a remote precision measurement for a length was successfully achieved with an error of about 60 nm (1 nm = 10-9 m). While in the conventional “take-in” calibration, the error is as small as 30 nm, the accuracy of the present measurement is adequate for the practical purpose, demonstrating the effectiveness of remote calibration for a length standard via optical fiber communication network.

The success in the remote calibration technology will allow users to acquire a traceable length value for a national standard through the optical fiber network while keeping their own length standard in the laboratory. This makes it possible to avoid the risk of damage or loss in the course of transportation, as well as to reduce the number of days required for calibration. The utilization of the optical fiber communication network will make every user including small and medium enterprises and research laboratory accessible to the national standard for length.

The future efforts will be dedicated to the validation experiment through optical fiber networks up to calibration laboratories of actual authorized suppliers and users and to the demonstration at large production plants, setting a goal at the practical application in a couple of years.

|

|

Photo. A block gauge

|

Background

Currently, the length standard is supplied on the basis of the Japan Calibration Service System (JCSS) with a series of standards, ranging from the primary standard, “iodine-stabilized He-Ne laser”, national standard, followed by “practical stabilized laser”, “laser photon interferometer”, and finally, artificial standards such as “end standard”. In particular, the block gauge, one of end standards, is most widely used as practical length standard. For calibrating a block gauge, a user has been required earlier to send the gauge itself to a standard laboratory (so-called take-in calibration), involving certain demerits such as a risk of loss or damage during the transportation, and taking time for shuttling. Nowadays, a hundred of thousands or more calibration sessions a year are being made for block gauges in Japan, and it has been urgently demanded to improve the efficiency of the calibration process in respect to cost, risk and speed.

History of R&D Work

The present study has been carried out under a contract project “Remote calibration system based on information technology” (Fiscal 2001~05) sponsored by the New Energy and Industrial Technology Development Organization (NEDO), another independent administrative organization. The Project nicknamed “e-trace” aims at the development of technology for massive remote calibration of 8 categories of physical quantity: time, length, electricity, radioactivity, temperature, 3-dimensional measure, flow rate and pressure. For the category of length, the development has been targeted at “Remote Calibration Technology for Length Standard by Use of Optical Fiber Network”. To speak more specifically, it is intended to develop technology for exact transmission of length data with tandem type low coherence interferometers connected by optical fiber network, to establish an innovative and practical length calibration technology scheme. With this achievement, it may be expected not only that a traceability system matched to the present info-oriented society, but also that the standard supply, the fundamental basis of quality assurance, will be provided with elimination of geographical difference, upgraded accuracy, labor saving, reduced calibration days and improved efficiency of technical probation.

Details of R&D Work

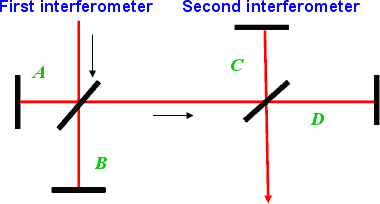

· Principle of Tandem Type Low Coherence Interferometer

The low coherence interferometer using light of broad spectrum of wavelength (low coherence light or white light) as a source generates interference fringe signal only when the difference in optical path length within the interferometer is zero. In the tandem type low coherence interferometer, where two interferometers are combined in series, the fringe signal is generated only when the difference in optical path lengths in two interferometers is compensated in unison. It is possible, therefore, to compare the difference in optical path length between two low coherence interferometers placed remotely separated locations, if connected with a single mode optical fiber network. If a low coherence interferometer is placed at a standard laboratory, and an optical path length difference is given by use of a precision movable stage, the optical path length difference data is transmitted to a remotely located user in the form of optical signal through optical fiber. Another low coherence interferometer is placed in the user's calibration laboratory, and if an optical path length difference is given by the device to be measured to determine a position generating fringe signal, the length of the tool can be calibrated by using the movable stage at the standard laboratory.

|

Fig.1. Principle of tandem type low coherence interferometer

Fringe signal occurs when the optical path length difference meets the following relation: (A + D) = (B + C). |

· Success in principle verifying experiment for remote precision length measurement with a block gauge via 10 m long optical fiber through the calibration based on tandem type low coherence interferometer (AIST Press Release, March 19, 2003).

The NMIJ-AIST has carried out a principle verifying experiment for remote precision length measurement with a block gauge of nominal length up to 10 mm via a single mode optical fiber 10 m long, base on the measurement using tandem type low coherence interferometer. As a result, the measurement with an error as small as about 140 nm has been achieved, validating the feasibility of remote calibration of length standard in principle (AIST Press Release, March 19, 2003).

· Success in demonstration experiment for remote precision length measurement with a block gauge via 47 km long optical fiber communication network through the calibration based on tandem type low coherence interferometer

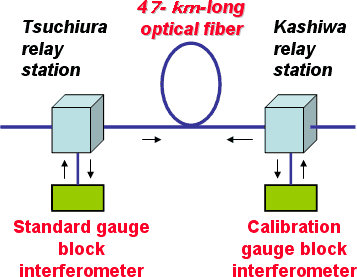

In order to find the application of remote calibration among a great number of users, it is necessary to demonstrate its effectiveness in a verifying experiment using the existing optical fiber network. For this purpose, a verifying experiment for remote precision length measurement with a block gauge through an existing optical fiber communication network of about 47 km length has been carried out between virtual relay stations located at Tsuchiura-city, Ibaraki and Kashiwa-city, Chiba through the measurement based on the tandem type low coherence interferometer. It has been assumed that the Tsuchiura-city Station is a standard laboratory. Light from a broad spectrum source of 1.5µm band corresponding to the optical communication wavelength band is fed into the optical fiber, and led to a low coherence interferometer to be measured placed at the Kashiwa-city Station, assumed to be an authorized supplier or user via a 47 km long optical fiber network. Light reflected from the latter interferometer is fed again into the optical fiber, to be returned to the standard low coherence interferometer placed at the Tsuchiura-city Station. As low coherence interference fringe occurs only when the two block gauges have an identical dimension, it is possible to compare exactly the length of test block gauge with that of standard block gauge. In this experiment, an error as small as 60 nm can be detected. While in the conventional “take-in” calibration, the error is as small as 30 nm, the accuracy of the present measurement is adequate for the practical purpose, demonstrating the effectiveness of remote calibration for a length standard via optical fiber communication network. In this experiment, conditions of measuring environment may be different from those of the normal environment. If the environmental conditions could be controlled more precisely, better accuracy might be achieved.

|

Fig2 A schematic diagram for remote calibration experiment for length standard by using an existing optical fiber communication network about 47 km long between Tsuchiura-city and Kashiwa-city. |

*In the remote precision length measurement experiment using 10 m long single mode optical fiber described in “Development of Remote Calibration Technology for Length Standard by Use of Optical Fiber” (AIST Press Release, March 19, 2003), a light source of 800 nm visible light was used. The failure of using the wavelength corresponding to the optical communication wavelength band may be the cause of resulting in greater error.