Dr. Akira Kurokawa, a senior researcher, and his colleagues of the Active State Research Group (ASRG) in the Research Institute of Instrumentation Frontier (RIIF) of the National Institute of Advanced Industrial Science and Technology (AIST), an independent administrative institution, has developed a small-sized ozone concentration gauge covering UHC ozone gas (80 vol% or higher) to determine the ozone concentration in oxygen-ozone binary gas mixture in collaboration with Vacuum Products, Co., Ltd. (VP). The gauge is based on the binary gas concentration determining technology previously developed by the RIIF-AIST.

Ozone (O3) with high oxidizing capability, exercises effective actions such as sterilizing, deodorizing, bleaching, water quality improving, and so on, with concentration as low as a few parts per million (ppm), and has been used widely in various areas. In the industrial applications, ozone gas is used in higher concentrations, a few vol% or so, and for the sake of securing elevated reaction efficiency, ozone utilization at even higher concentration has been increasingly requested.

UHC ozone gas, higher than 80 vol% , is expected to be applied in the preparatory process for semiconductor devices owing to its extremely high oxidizing capability. In fact, the merit of using UHC ozone gas has been demonstrated in oxidizing treatment for hardly oxidized electronic materials such as silicon carbide (SiC) and in production of high quality silicon dioxide film for electronic devices with a temperature lower than 400 ºC. In order to extend the application of UHC ozone gas to real processes such as preparation of semiconductor devices, it is essential to provide continuous monitoring technique for ozone concentration for the sake of various control means. Since the processing time and the reaction duration are sensitively affected by the concentration of UHC ozone gas, it is necessary to monitor exactly the concentration of ozone in the ozone generating plant and the ozone using process.

Up to now, no measuring instrument has been available for continuously and stably monitoring the concentration of UHC ozone gas. The conventional system based on ultraviolet absorption photometry for lower ozone concentration (5 vol% or lower) fails to determine exactly the ozone concentration under varying gas pressure, and its capability of stable measurement is doubted because of high reactivity and easy decomposition of UHC ozone gas.

The RIIF-AIST has developed a small-sized ozone concentration gauge based on the binary gas concentration determining method in collaboration with VP. The gauge is characterized by the lack of factors for decomposing high concentration ozone gas such as UV radiation source and heat source in the conventional systems, which makes it possible to measure the ozone concentration even with limited sample quantity. Besides, the gauge can be directly installed in the ozone gas supply pipe to make the ozone elimination dispensable, needed in the conventional system for detoxifying remaining sample gas after the measurement. Owing to simple construction, the sensor part can be miniaturized (sensor unit: 15 x 6 x 6 cm, main body: 9 x 20 x 33 cm). The response time for measurement, faster than 1 s, is shorter than that in the commercially available based on the conventional technology. The pressure coverage, from 1/10 to 1 atm. is also larger than that in the conventional system. The concentration coverage is 0~100 vol%, in contrast to 0~10 vol% in the conventional one.

The future R&D efforts of the AIST-VP team will be focused on upgrading accuracy and verifying stability in the measurement with the gauge. The commercialization of the gauge is expected to be achieved by the end of fiscal 2004.

The result of this study will be exhibited at the "ZENKATEN in TOKYO (Science & Technology Exhibition) 2004" to be held December 1~3 at the Tokyo Big Site (Tokyo International Exhibition, Ariake, Koto-ku, Tokyo).

Ozone (O3) with high oxidizing capability exerts marked action efficiency for sterilization, decoration, water quality improvement, etc. even with ozone concentration as low as a few ppm. It has been widely applied to varied areas, including elimination of fusty smell in water purifying process, industrial waste water disposal, sterilization of swimming pool water, deodorization or purification of room air by elimination of foul smell ingredients (such as methane, amine and hydrogen sulfide), eradication of floating microbes, sterilization with ozone-dissolving water at hospitals, food processing plants and kitchens, and so on. In the industrial fields, highly concentrated ozone gas higher than a few vol% has been used for bleaching of paper pulp, precision cleaning of substrate and photoresist removal in the semiconductor manufacturing. In these fields, the use of ozone with much higher concentration has been urgently demanded in view of upgrading the reactivity and reducing process time.

UHC ozone gas, higher than 80 vol%, is expected to be applied to the semiconductor preparatory process owing to its extremely high oxidizing capability. In case of SiC materials, difficult to oxidize, oxide film for electron devices was formed previously by oxidation using oxygen at higher temperatures and for longer time period. If UHC ozone is used, time required for treatment is reduced by an order of magnitude, and the resultant device is found to give better quality. For liquid crystal display, UHC ozone may be utilized for high quality silicon oxide film formation at temperatures lower than 400 ºC. In this way, the use of UHC ozone gas will be further expanded. For using UHC ozone gas as a regular means in the real process, it is essential to establish means of continuously monitoring ozone concentration for the purpose of various control actions. If this means is available, the UHC ozone generator can be controlled so as to provide ozone gas at a fixed concentration. In case of an ozone-governed process where reaction rate is affected by the ozone concentration, it may become possible to minimize the fluctuation in quality of products through the concentration management. Nevertheless, there has been available no measuring instrument for stably monitoring the concentration of UHC ozone up to now.

Earlier, the ultraviolet absorption photometry (UVAP) has been used for determining ozone concentration lower than 5 vol%. With this technique, however, it is inevitable that the measuring accuracy is made poorer depending upon variation in the gas pressure to be measured, which affects the amount of ozone in unit volume of gas, and hence, the UV absorption. Furthermore, ozone gas at concentration higher than 50 vol% is readily triggered by heat and/or light for explosion and inflammation. In this way, the UVAP method involves safety problems in handling UHC ozone gas. Additionally, since ozone gas is decomposed by UV irradiation for measurement, it is necessary for keeping good accuracy to use adequate volume of sample gas (0.5 to 2.0 liter per minute) for making the decomposition ignorable. The remaining sample gas containing ozone has to be detoxified after the measurement.

Under such circumstances, continuous measurement for UHC ozone is required without being affected by variations in gas pressure, in order to secure reliable industrial application such as oxidizing process.

Dr. Shingo Ichimura, Director, and Dr. Akira Kurokawa, Senior Researcher, with their colleagues in the RIIF-AIST have noted the technology for measuring gas viscosity with quartz oscillator, and been developing the instrumentation for UHC ozone gas. In order to achieve the practical application of the ozone concentration gauge covering UHC ozone, materials neither affecting nor affected by ozone have been sought for, and the effectiveness of quarts-based concentration determination has been verified in collaboration with VP where pressure gauge using quartz oscillator has been developed.

The R&D work has been carried out as a part of the "Collaboration for Commercialization of Patented Technologies" Project (FY04) under the AIST's Regional Small and Medium Enterprise Supporting Program (FY03).

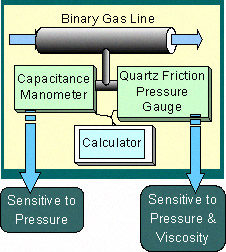

The RIIF-AIST has developed technology for determining concentration of binary gas mixture based on the correlation of gas viscosity with concentration. The gas viscosity is to be determined by measuring the force acting upon a quartz oscillator driven within sample gas. The concentration sensor consists of a viscosity-based pressure gauge and a pressure-sensitive pressure gauge. Since the former responds to both viscosity and pressure, it is necessary to eliminate the pressure component. The instrument measures the pressure of sample gas with the two sensors, and computes the viscosity component by subtracting the pressure component, and converts it to the concentration by use of the concentration computer

|

|

Fig. 1.Principle diagram of ozone concentration gauge: The pressure of binary gas mixture is measured with two different pressure sensors. The viscosity-based sensor responds to both viscosity and pressure, while the pressure-sensitive sensor is responsive to pressure only. The instrument extracts the viscosity component by subtracting the pressure component. The computer converts the viscosity component into the concentration. In this diagram, the temperature is assumed to be constant.

|

The use of quarts oscillator has the following merits: 1) The measurement involves none of factors to decompose highly concentrated ozone gas such as UV radiation source or heat source in the conventional system, which makes it possible to determine the ozone concentration exactly even with a small amount of sample gas. 2) The instrument can be installed directly on ozone gas supply piping and no disposing treatment for sample gas to make it harmless is needed for detoxifying ozone in contrast to the conventional method. 3) As the measurement uses neither heat nor irradiation, the instrument involves no risk of explosion or inflammation of UHC ozone gas triggered by UV irradiation. 4) As the instrument consists of pressure sensors, the measurement is least affected by variations in pressure of sample gas. 5) Owing to simple sensor construction with quartz oscillator and pressure gauge, the instrument can be miniaturized drastically. (quartz oscillator: a tuning fork 4 mm long, sensor unit: 15 x 6 x 6 cm, main unit: 9 x 20 x 33 cm) [Fig. 2]. 6) The response to pressure change is 1 s or less in contrast to 20~30 s in the conventional system, the pressure range covers 1 atm. to subatmospheric (mostly fixed at 1 atm), and the concentration range from 0 to 100 vol%, in contrast to the conventional system where the upper limit is 10 vol% or so.

|

|

Fig. 2. An outer view of the small-sized ozone concentration gauge, consisting of sensor unit (right) and main unit (left). The inset shows a magnified view of quartz oscillator within the sensor unit. While the concentration and the pressure are measured simultaneously, the main unit display indicates two readings in a switched mode alternately.

|

VP has developed the "small-sized ozone concentration gauge" covering UHC ozone gas on the basis of binary gas mixture concentration measurement in collaboration with the RIIF-AIST [Fig. 2]. The specifications for the concentration gauge is as following: measurable ozone concentration 0~100 vol%, resolution 0.5 vol%, response time 1 s or shorter, pressure range 1~1/10 atm (10~110 kPa) (kPa = kilo Pascal, 1 atm = 101.3 kPa). The sensor unit can be installed within the gas supply pipes, and the decomposition of ozone is suppressed by selecting materials of very little ozone decomposition and by the surface treatment. For this reason, ozone gas can be used as it is without being discarded. This makes it possible to utilize ozone gas effectively and to dispense ozone detoxification. The future efforts will be paid to the durability test and upgrading the accuracy, aiming at the commercialization starting from the prototype described here.