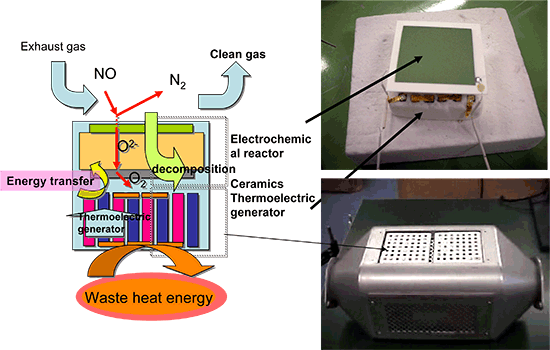

The Advanced Manufacturing Research Institute (AMRI) of the National Institute of Advanced Industrial Science and Technology (AIST), an independent administrative institution, has developed technology for manufacturing an innovative ceramics reactor incorporated with a feature of driving a self-consistent electrochemical reactor through thermoelectric power generation using exhaust heat. The achievement is expected to open the way to practical application of new ceramics reactor to purge NOx and other exhaust gas [Fig. 1 and 2].

The technology will further accelerate the development of ceramics reactor and relevant sensors to control electrochemical reactions without needing outside power supply and other auxiliary equipment. The R&D work will be reported at the Lecture Meeting of Chubu Research Base, AIST, to be held at the Nagoya International Conference Hall on Monday, November 15, 2004.

-

Reductive purge of NOx by use of electrochemical reaction constitutes a crucial technology toward zero emission, requiring no reducing agent and emitting no secondary waste resulting from the decomposition, but its operation needs outside power supply.

-

The AMRI-AIST has developed technology for manufacturing innovative, zirconia-based electrochemical reactor to produce electric power for NOx decomposition in a self-consistent manner through thermoelectric conversion of exhaust heat by using thermally stable thermoelectric conversion ceramic materials

-

The new system will extensively contribute to the commercialization of electrochemical ceramics reactor because the electrochemical reactor and sensor are driven by using electric power generated within through conversion of thermal energy derived from exhaust heat, and burden to outside power supply does not matter., and because the conventional NOx purging system based on catalyst can be replaced as a whole by the electrochemical reactor without requiring extra wiring.

The future efforts will be directed to the expansion of this technology to electrochemical purging and sensing for organic components using exhaust heat or differential temperatures, as well as to development of self-generating ceramics reactor without relying on outside energy supply.

|

|

Fig. 1. Operational principle of electrochemical ceramics reactor based on power generated by using exhaust heat.

|

Fig. 2. Newly developed electrochemical ceramics reactor based on power generation from exhaust heat, and its installation.

|

Energy saving and environmental conservation constitute one of crucial social issues. NOx contained in high temperature exhaust gas from automobiles is air-pollutant and reduction of its emission is strongly requested. Recently, in regard to the automobile engine, it has been pursued to change over to lean burn type using diluted gasoline and diesel type to improve fuel efficiency, for the purpose of reducing fossil fuel consumption and cutting down carbon dioxide emission. However, the higher oxygen concentration in the combustion process leads to richer oxygen in exhaust gas, which makes difficult continued decomposition of NOx with the conventional ternary reductive catalyst. For this reason, the development of purging technology to cope with oxygen-rich exhaust gas from high mileage engine has been urgently demanded worldwide. The AMRI-AIST has been engaged in R&D of technology of electrochemical purging for NOx by using electrochemical reactor based on ion-conductive ceramics, and succeeded in decomposing NOx in oxygen-rich (3 % or more) gas mixture into N2 and O2 with an electrochemical reactor selectively and continuously, using very little electric power. The technology is attracting worldwide attention as zero emission purging, characterized by directly decomposing NOx by electrical means, in comparison to the conventional catalytic method with combined reductive agents. On the other hand, the electrochemical reactor system requires electric power to drive the reactor, in contrast to the catalyst method. As one of means to solve this problem, it has been attempted to provide electric power for driving the electrochemical reactor through power generation based on temperature difference between exhaust heat in waste gas and atmosphere by using thermoelectric conversion ceramics.

The thermoelectric conversion ceramics refers to electro-conductive ceramic materials characterized by high electromotive force and good stability in high temperature atmosphere. In the present study, aluminum doped zinc oxide ceramic device, one of n-type oxide semiconductors, is combined in paired structures, with p-type calcium-cobalt oxide ceramic device, prepared by ceramic structure control process. With this module, one end of the junction is heated, while the other is air-cooled, to generate thermal electromotive force. It has been demonstrated that the thermoelectric conversion as high as 40mW/cm2 is obtained for a temperature difference of 500ºC with a pair of thermoelectric ceramic devices. Moreover, the characterization of a compound module prepared by combining in series 37 pairs of 2 x 2 x 20 mm rectangular solid modules has proved to generate 300mW power (at 3.5V) for around 650ºC temperature difference (with one end of junction heated to 800ºC while air-cooling the other, verifying the availability of the module as power supply for NOx purging electrochemical reactor.

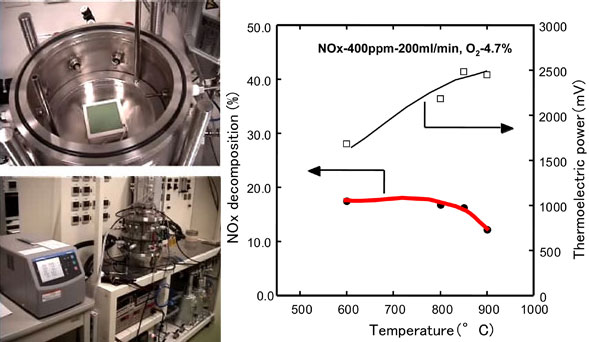

For demonstrating the self-consistent operation of power generation through thermoelectric conversion from exhaust heat combined with electrochemical cells using this power, an integrated module is constructed by combining a power unit made of thermoelectric power generating ceramic devices connected in series 18 pairs of newly developed devices, with an electrochemical reactor consisting of 5-cm square 8Y-ZrO2 (8YSZ) ceramic board and electrodes with high selectivity for NOx reaction. With this system, an experimental test has been carried out by creating a temperature difference by feeding mixed gas consisting of 400 ppm NOx and 4 % O2 heated to 600 ºC to demonstrate the power generation and NOx decomposition by electrochemical cell. Consequently, it has been proved that as much as about 20 % of NOx is decomposed continuously at the electrochemical cell with power generated by thermoelectric ceramics (around 1.5V-35mW). In this way, the self-consistent operation of electrochemical device by using electric power generated by thermoelectric conversion materials without relying on outside power supply, leading the world [Fig. 3].

|

Fig. 3. Purging of NOx by newly developed electrochemical reactor

using power generated by thermoelectric conversion of thermal energy derived from exhaust heat.

|