– Efficient synthesis of materials such as pigment dyes, pharmaceuticals, and battery materials using hydrogen –

Researchers) MIYAMURA Hiroyuki, Senior Researcher, KON Yoshihiro, Team Leader, KOBAYASHI Shū, Joint Appointed Fellow, Interdisciplinary Research Center for Catalytic Chemistry

- Development of bimetallic nanoparticle catalysts that exhibit high activity and selectivity by combining appropriate metal species

- Achieved the world's first leuco-quinizarin synthesis by a continuous production flow process using hydrogen as a feedstock

- Continuous synthesis of anthraquinone derivatives useful as functional materials by integrated continuous production flow processes

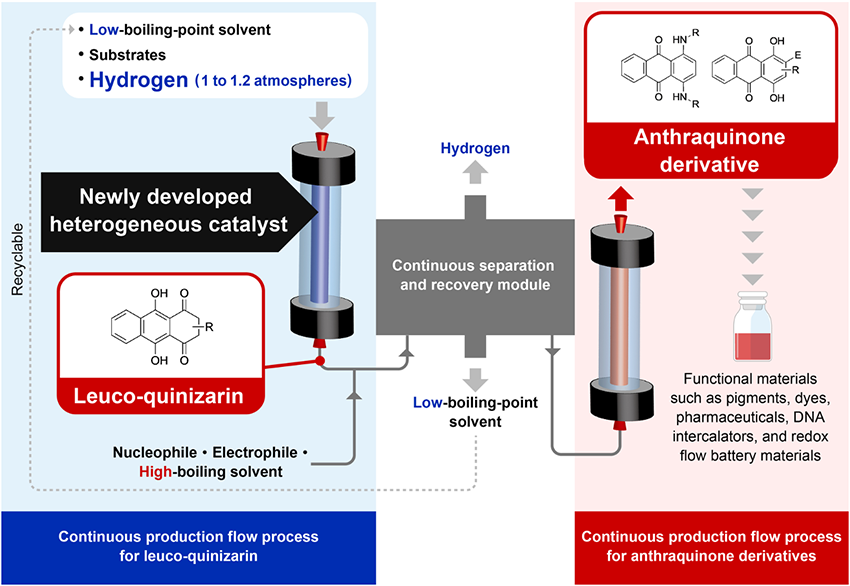

Continuous production flow process for functional materials, characterized by leuco-quinizarin synthesis using bimetallic nanoparticle catalysts and hydrogen.

In recent years, as organic synthesis methods and production processes for functional materials with low environmental impact have been attracting attention, technologies for highly functional catalysts and highly efficient chemical processes are desired to realize a material- and energy-saving society. Reduction reactions are essential in the synthesis of functional materials such as pharmaceuticals and organic electronic materials, and many methods require the consumption of stoichiometric amount of inorganic reducing agents containing metals. However, such conventional reactions generate large quantities of metal-containing and hazardous wastes, and also require energy and material consumption for separation and purification of the target products.

AIST researchers have developed highly active and selective metal nanoparticle catalysts, and have achieved an environmentally friendly organic synthesis method with these heterogeneous catalysts using continuous production flow process technology.

This technology is a method for synthesizing functional materials by direct flow of hydrogen and substrates using a newly developed heterogeneous catalyst and newly designed continuous-flow synthesis equipment or continuous separation and purification modules. This time, leuco-quinizarins, which are key intermediate to be converted to various functional materials such as pigment dyes, pharmaceuticals, and energy materials, were successfully synthesized catalytically using hydrogen as a reducing agent in highly selective manner for the first time in the world.

Conventional leuco-quinizarin synthesis methods consume stoichiometric amounts of inorganic reagents and generate potentially hazardous waste. The newly developed method, on the other hand, is characterized by a heterogeneous catalyst that can be used over a long period of time under continuous-flow conditions, and by the fact that it only consumes hydrogen, an environmentally friendly reductant, and produces no waste, thus realizing an environmentally friendly organic synthesis. Furthermore, we have newly developed a continuous separation and recovery module unified with function of a batch reactor that can not only separate and recover solvents and hydrogen but also can convert in-situ generated leuco-quinizarin to various anthraquinone derivatives. By coupling this continuous separation and recovery module unified with function of a batch reactor with a continuous-flow hydrogenation system for synthesis of leuco-quinizarin, we have succeeded in continuous production of anthraquinone derivatives as a functional material from inexpensive raw materials. The newly developed continuous-flow synthesis technology will contribute to the development of continuous synthesis processes for functional materials with complex structures, since it can be coupled with other continuous synthesis equipment to realize further multi-step continuous synthesis methods.