– Cutting-edge integrated circuit design techniques stabilize sensor sensitivity and expand applications –

Researchers) AKITA Ippei, Senior Researcher, Integrated Circuit Design Research Team, Semiconductor Frontier Research Center

- Developed application-specific integrated circuits (ASICs) with digital outputs to be combined with magnetic impedance elements

- Digital automatic calibration technique enables robust measurement even with fluctuating power supply voltage

- Contributes to high-precision magnetic sensing in industrial, environmental, and biological measurements

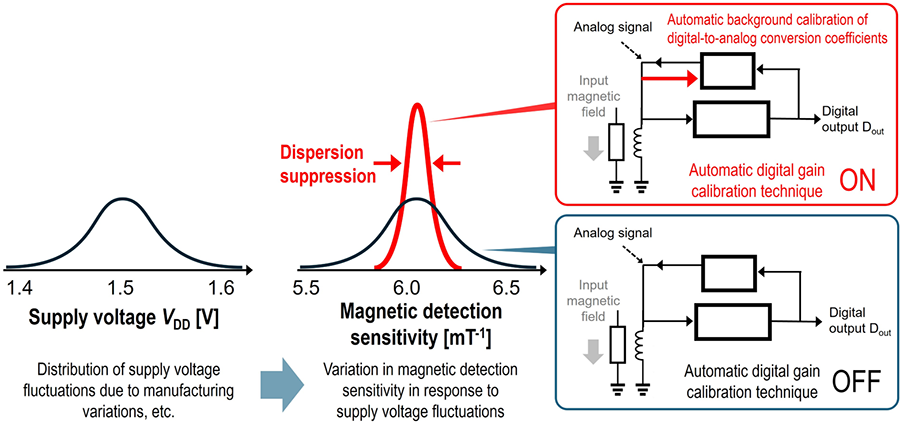

Improved detection sensitivity variation of the developed magnetic sensor

A researcher at AIST, in collaboration with Aichi Steel Corporation, has developed a highly sensitive magnetic sensor that can automatically compensate for fluctuations in detection sensitivity due to manufacturing variations and environmental changes.

Compact, highly sensitive magnetic sensors are needed in a wide variety of applications, including industrial and biological measurement. To apply them to fields such as IoT, their sensitivity must be maintained at a constant level. The cost of manually adjusting sensitivity has hindered the expansion of applications for small, high-sensitivity magnetic sensors.

By combining an application-specific integrated circuit (hereinafter referred to as "ASIC") with an automatic correction function originally designed by AIST and a magnetic impedance element (hereinafter referred to as "MI element") developed by Aichi Steel Corporation, the fluctuation of the magnetic detection sensitivity was reduced to 1/3 of its original level. This automatic calibration technique does not require a special test mode for the process, and can be performed in the background during normal sensing operation. The digital-output architecture achieves both easy handling of output signals and low power consumption. This approach is expected to expand the range of applications for compact, high-sensitivity magnetic sensors.

Compact, high-sensitivity magnetic sensors are suitable for a wide range of fields, including industrial measurement such as current sensing, nondestructive testing, environmental sensing for IoT, and biomagnetic measurement such as magnetoencephalography and magnetic electromyography. These applications require a low-noise characteristic at the picotesla (pT) level and a high dynamic range without saturation in the geomagnetic field. In addition, small size and low power consumption are desired, so ASIC design plays an important role and it is required to be a digital signal output type that allows users to easily handle it.

Although several types of high-sensitivity magnetic sensors with digital output have been presented, environmental variations such as fluctuations in supply voltage and temperature, as well as manufacturing variations, can cause variations in magnetic detection sensitivity. Such variations are usually trimmed by manual adjustments to individual magnetic sensors, which increases the cost of the sensor due to the additional testing process. If this variation in magnetic detection sensitivity can be suppressed using integrated circuit design technique, high-performance and low-cost magnetic sensors can be realized, accelerating their implementation in society, especially for IoT applications.