– Development of low-friction technology will contribute to more efficient energy utilization –

Researchers) MANABE Kengo, Senior Researcher, NORIKANE Yasuo, Group Leader, Molecular Assembly Group, Research Institute for Advanced Electronics and Photonics, NAKANO Miki, Senior Researcher, Tribology Group, Advanced Manufacturing Research Institute

- Development of a surface technology that can retain both plant oil and water

- Autonomous movement of water to the optimal position during sliding achieves superlubricity even with a small amount of water

- An superlubricated surface will contribute to reduce cost and energy loss with low environmental impact

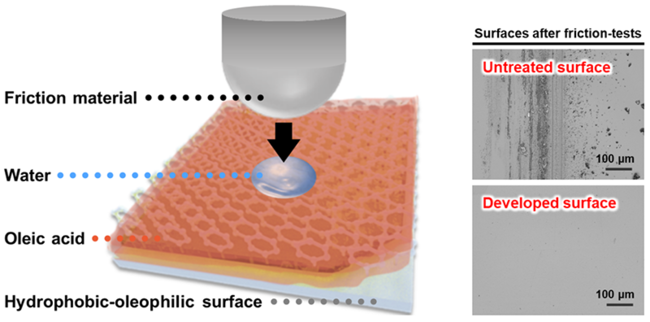

Schematic diagram of superlubricated surface (left) and results of surface observation after rubbing (right). Surface obtained by placing water on oleic acid spread on the surface of a hydrophobic-oleophilic treated material.

Friction at interfaces is a cause of damage, deterioration, and energy loss in automobiles and industrial equipment, etc. Establishment of low-friction technology is an important R&D theme as it leads to drastic increases in energy utilization efficiency and as a result can be expected to effectively reduce CO2 emissions. Large amounts of lubricating oil or expensive lubricants such as graphene have conventionally been used to obtain low-friction surfaces and in particular superlubric state with a friction coefficient of 0.01 or less. However, applicability is limited due to environmental and cost concerns. In addition, lubricating fluids with low environmental impact such as water and ethanol are attracting attention, and water-based lubricating fluids in particular are considered promising as these are abundant and low-cost resources. However, low viscosity makes it difficult to both retain the fluid at the interface and create a liquid film with sufficient thickness, so it has been a challenge to obtain stable low-friction properties with a small amount.

AIST researchers achieved superlubricated surface with a friction coefficient of 0.01 or less. The surface that retains multiple lubricating fluids was developed by spreading oleic acid, which is a component of plant oil, on a hydrophobic-oleophilic treated material surface and placing water on that oil surface.

Friction has conventionally been reduced by using large amounts of lubricating oil or expensive lubricants such as graphene. However, the developed technology can achieve superlubric state with only plant oil spread thinly over a hydrophobic-oleophilic treated material surface and a small amount of water. This technology achieves a superlubricated fluid surface that is low cost and has low environmental impact simply by adding water on a lubricating oil film at the contact sites of equipment that requires low friction. As such, application is expected to contribute to reduction of CO2 emissions by reducing energy loss due to friction and promoting efficient use of energy in automobiles and industrial equipment, etc.