Researchers) SATO Yuya, Senior Researcher, HABE Hiroshi, Group Leader (at the time of the research), Environmental Function Engineering Research Group, Environmental Management Research Institute

- Sulfate reducing bacteria (SRB) using rice bran as nutrients detoxify acid mine drainage containing heavy metals

- Identification of the key SRB has made the treatment system easier to manage

- Optimization of the operation conditions has enabled the elimination of the preparation period before the start of operation

Removal of heavy metals from acid mine drainage using microbes, rice husk, and rice bran

Acid mine drainage containing heavy metals could continue to flow out from mine sites where excavation has been suspended or stopped, and treatment of that wastewater must continue for a long period. However, neutralization treatment of the wastewater requires special equipment and chemicals, and reduction of treatment costs and environmental impact are major issues.

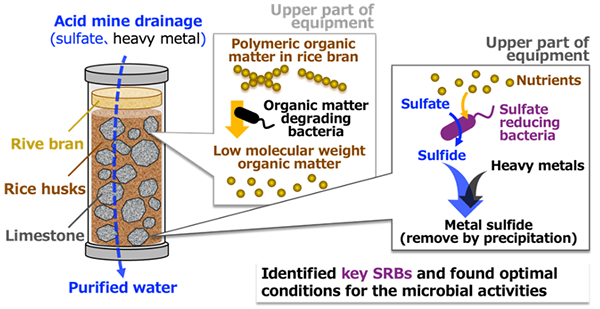

The Japan Oil, Gas and Metals National Corporation (JOGMEC) has developed the treatment system for acid mine drainage that utilizes microbial activity with the agricultural wastes rice husk and rice bran as the carrier and nutrient source, respectively. Two different microbes are mainly functioning inside the bioreactor. One is organic matter-degrading bacteria that decompose polymeric organic matter derived from rice bran into low-molecular-weight organic matters, which other microbes can easily utilize as nutrients, in the upper part of the equipment. The other one is sulfate-reducing bacteria, which are responsible for the sulfate reduction reaction that converts sulfate into sulfide using organic matters as nutrients. Sulfide ions react with heavy metals to generate metal sulfides, and as a result the heavy metals precipitate inside the equipment and are removed. These microbes could attach and proliferate on the surface of rice husk, so the rice husk functions as a carrier for maintaining the microbes inside the bioreactor.

However, there are more than thousands of kinds of microbes inside the bioreactor, and it was unclear which of the multiple types of sulfate-reducing bacteria was the key, so optimal conditions for stably maintaining the bioreactor performance had yet to be elucidated. Anaerobicity (oxidation-reduction potential) is generally used as an index for management of the sulfate reduction bioreactor, but the treatment performance of the equipment was not stable enough even at the same anaerobicity, and the reason was unknown.

In collaboration with JOGMEC, National Institute of Advanced Industrial Science and Technology (AIST) developed a treatment technology for acid mine drainage containing heavy metals utilizing sulfate-reducing bacteria in the presence of rice bran as a nutrient source.

AIST and JOGMEC worked to identify microbes that are critical for the stable bioreactor performance and optimize the operating conditions. The results indicated that only one sulfate-reducing bacteria was exceptionally tolerant of relatively aerobic environments, and that maintaining the activity of this bacterium could be important for stable wastewater treatment. Since this system can remove heavy metals from the wastewater with low cost and low environmental impact, it will be also applied to industrial wastewater.