Researchers) BAGARINAO Katherine, Senior Researcher, KISHIMOTO Haruo, Team Leader, Fundamentals of Ionic Devices Research Team, Global Zero Emission Research Center, YAMAJI Katsuhiko, Group Leader, ISHIYAMA Tomohiro, Senior Researcher, Energy Conversion Technology Group, Research Institute for Energy Conservation, SHIMADA Hiroyuki, Senior Researcher, Solid State Ionics Materials Group, Innovative Functional Materials Research Institute

- Realization of higher performance by nanometer-scale control of the SOFC air electrode structure

- Achieved world top-level power generation performance via the technology for fabricating SOFC single cells that take advantage of the capability of high-performance air electrodes

- Contributes to reduction of SOFC system size and manufacturing costs

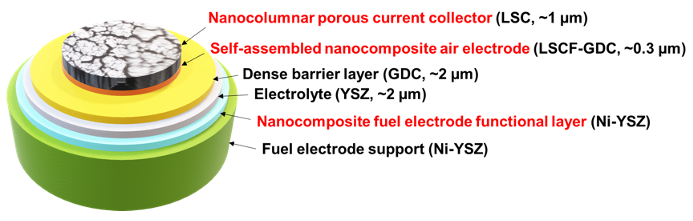

Schematic diagram of fuel-electrode-supported SOFC single cell that achieved world top-level power generation performance: Red text indicates newly developed materials

Solid oxide fuel cells (SOFCs) have high power generation efficiency compared to other fuel cells and have already been marketed as fuel cell cogeneration systems for home and business use. Recently, SOFCs are also increasingly used for applications with larger power generation capacity and monogeneration systems that take advantage of the high power generation efficiency.

System size and manufacturing cost are issues for the widespread use of SOFCs. If the power generation performance of SOFC single cells can be increased, then the number of SOFC single cells used can be reduced compared to conventional SOFC systems with the same power generation capacity, and size and cost reduction can be expected.

Researchers in AIST developed a nanostructure-controlled high-performance air electrode in a study performed under the Advanced Technology Consortium for Solid State Energy Conversion (ASEC), which is engaged in strategic joint research with multiple companies. In addition, an SOFC single cell equipped with the developed electrode exhibited world top-level power generation performance.

In addition to the self-assembled nanocomposite air electrode fabricated using the pulsed laser deposition (PLD) method, the SOFC single cell is equipped with a nanocolumnar porous current collector and nanocomposite fuel electrode functional layer, which were developed to fully demonstrate the performance of the air electrode. The resulting single cell achieved the world top-level power density of 4.5 W/cm2 or more at 700 °C. This achievement will contribute to the reduction of the SOFC cell stack size and manufacturing costs.

Details of the results were published in the open access journal Nature Communications (electronic version) on June 25, 2021.