– The film is expected to be used as an agricultural film with excellent UV absorption and permeability –

Researchers: ISHII Ryo, Leader, and SHIKINAKA Kazuhiro, Senior Researcher, Functional Materials Processing Group, Research Institute for Chemical Process Technology

The researchers have developed a transparent UV protection film with excellent moisture permeability that consists of only lignin and clay components, in collaboration with the Forestry and Forest Products Research Institute.

|

|

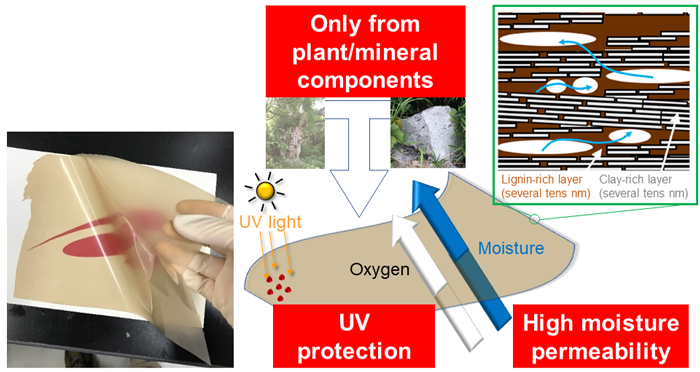

Photograph of the developed film (left) and schematics of functions and cross-sectional structure of the film (right) |

Recently, the agricultural sector is increasingly concerned about expanding pest insect damage caused by rising temperatures due to the global warming. When employing a typical insect deterrent net to prevent damage by pest insects, it is also necessary to use pesticides. However, many pest insects exhibit phototaxis to ultraviolet light (UV), so demand for agricultural covering materials with UV protection property (vinyl greenhouse films, mulch films, etc.) is increasing to prevent an invasion of pest insects. Furthermore, in order to realize a sustainable society, there are many attentions for development of functional materials consisting of plant and mineral components other than petroleum-derived components that reduce the environmental load.

A transparent moisture-permeable UV protection film, lignoclaist, was fabricated by using a lignin as component to CLAIST®. Lignoclaist has high UV absorption property (approximately 99% protection) and high moisture permeability (1,100 g/m2•day) unlike conventional CLAIST®. The moisture permeability of lignoclaist is on a par with conventional agricultural films and the UV absorption property of lignoclaist is better than that of conventional agricultural UV protection films. The high UV absorption property of lignoclaist is derived from the chromophores of lignin, and the high moisture permeability of lignoclaist is derived from voids created in lignin-rich layer that stacked with clay-rich layers on nanometer-scale.

The researchers will perform more wider performance evaluation of lignoclaist. At the same time, applications such as an agricultural covering material will be investigated in association with the industrial sector. Additionally, research and development for early commercialization of lignoclaist will be carried out. Furthermore, they will establish a supply system of the raw material of lignoclaist, lignin, via generalization and cost down of the simultaneous enzymatic saccharification and comminution method.