In collaboration with Toshima Manufacturing Co., Ltd. and E-ThermoGentek Co., Ltd., the researchers have developed a high-power flexible thermoelectric module with power generation performance 1.5 times higher than that of conventional modules. The developed module allows to be adhered to heat sources with curved surfaces and can be used for a variety of power generation applications using waste heat.

|

|

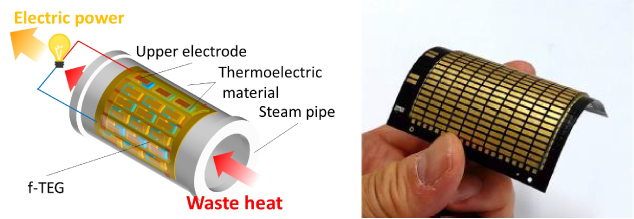

Developed high-power flexible thermoelectric module |

Unutilized low-temperature waste heat energy below 300 °C in the industrial sector alone is said to exceed the total annual power generation in Japan and needs to be used. The conventional planer-structured thermoelectric modules composed of rigid ceramic substrates are impossible to bend, so heat cannot be efficiently transferred from curved heat sources, such as pipes that account for most unutilized heat sources. A thermoelectric module for efficient heat recovery from curved surfaces thus needs to be developed.

The developed thermoelectric material is a transition metal-doped bismuth-tellurium alloy. The researcher found that it could increase the power factor, used as the index for power generation, by 1.5 times compared with the previous thermoelectric materials the researchers fabricated. The researchers produced thermoelectric chips from an ingot of this material and built a flexible thermoelectric module by mounting the chips at high density on a flexible substrate. The researchers evaluated its power generation performance at a maximum temperature difference of 70 °C and demonstrated that the maximum output power was 87 mW/cm2.

With a view to commercializing this technology, the researcher will move forward with joint development, including demonstrations of the long-term reliability of the developed flexible thermoelectric module and improvement of the performance of the developed thermoelectric material.