Update(MM/DD/YYYY):10/03/2018

Manufacturing Functional Materials from Incineration Residue of Burnable Garbage

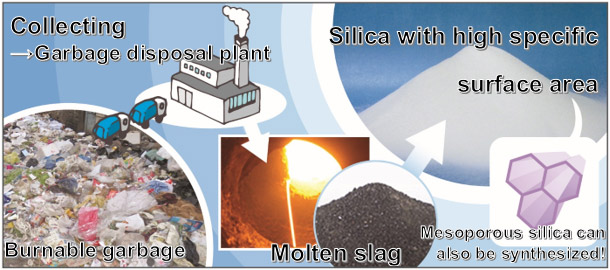

– Converting molten slag discharged from municipal garbage disposal plants into high specific surface area silica –

Researchers: Norihisa Fukaya, Senior Researcher, and Junchul Choi, Leader, the Catalyst Design Team, the Interdisciplinary Research Center for Catalytic Chemistry, Sho Kataoka, Senior Researcher, the Energy-efficient Chemical Systems Group, the Research Institute for Chemical Process Technology, and Mitsui Engineering & Shipbuilding Co., Ltd.

Summary

The researchers have developed a technology to produce high specific surface area silica, using melted slag that is discharged when treating burnable waste at municipal garbage disposal plants as a raw material.

|

|

Converting molten slag, which is incineration residue of burnable garbage, into high value-added materials |

Background

Garbage disposal plants that incinerate municipal waste generate incinerator ash in the process, and this ash is mainly buried at final disposal sites. Currently, in order to reduce the volume of incinerator ash, a process is used that melts incinerator ash at high temperatures then cools it in water, and recovers generated glass solids called “molten slag”. Molten slag is put to use as asphalt aggregate for building roads or concrete aggregate, but there is demand for more methods of effective use.

Created Method

The researchers have created high value-added materials using molten slag discharged from municipal garbage disposal plants. When molten slag is chemically treated using acidic solution under certain conditions, the silica (SiO2) component contained in the molten slag precipitates as a white solid which is not soluble in the treatment solution. If this solid is recovered by filtration etc., silica with a purity of 93% to 98% is obtained easily. This is a material with high specific surface area equal to or higher than that of synthetic silica, and is expected to have applications to various adsorbents. In addition, a white solid is obtained when it is subjected to chemical treatment. Baking this solid at 550° C yields mesoporous silica with regular nanometer-sized pores, which is expected to function as a high-performance humidity conditioner, as well as an adsorbent for hazardous substances in disposal plants (local production/local consumption).

Future Plans

The researchers aim at improvement of the reaction conditions, scaling up of the production, and practical applications in a few years.