– Accelerating the development of a writing technique of a voltage-controlled non-volatile magnetic memory with ultra-low power consumption –

The researchers have developed a technology that significantly reduces the writing error rate of a voltage-controlled magnetic memory (voltage torque MRAM).

|

|

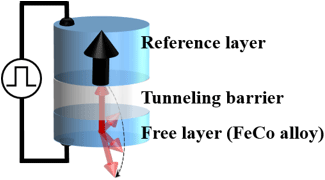

Fig. 1 Schematic diagram of magnetization reversal using pulsed voltage |

|

|

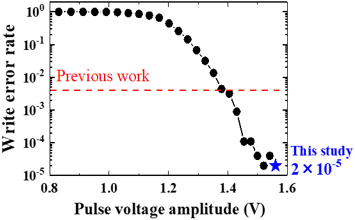

Fig. 2 Pulsed voltage strength dependence of writing error rate |

When applying pulsed voltage to a magnetic tunneling junction element having an ultrathin metal ferromagnetic layer (memory layer) for an extremely short time (in the order of nanoseconds), magnetization reversal can be induced (see Fig. 1). The researchers have optimized the magnetic characteristics of the memory layer to improve the efficiency of voltage-controlled magnetic anisotropy (VCMA) change and thermal stability. As a result, the writing error rate of a voltage torque MRAM was reduced by double digits or more (2 x 10-5) compared with past reported values (10-2 to 10-3) (see Fig. 2). The developed technique enables us to achieve the practical writing error rate, lower than 10-9, by introducing one error correction process.

In conventional MRAMs, electric current is used for information writing, but unnecessary power consumption caused by ohmic dissipation is a concern as an obstacle to reducing drive power. On the other hand, voltage torque MRAMs, expected to be the next-generation MRAMs, do not require electric current in principle, and therefore a significant reduction in power consumption is expected. However, a reduction in the writing error rate still remains a challenge.

The developed technology will accelerate the R&D of highly reliable and high-speed voltage torque MRAMs with ultra-low power consumption. Research for new materials, which have high VCMA efficiency, is crucial for further reduction in the writing error rate and will be developed. In addition, suppression of variations in magnetic and VCMA properties on large wafer and the development of circuit technology for voltage-torque MRAM will also be pursued.