– Realization of the world’s highest lithium-ion-conductivity of oxide-type electrolyte by using single-crystal solid electrolyte –

The researchers have grown a single crystal of oxide-type solid electrolyte with the highest lithium ion conductivity. In addition, they used the AD method, a room-temperature film forming technology developed by AIST, to form a strongly adhered electrode-electrolyte interface and have developed a compact all-solid-state lithium secondary battery.

|

|

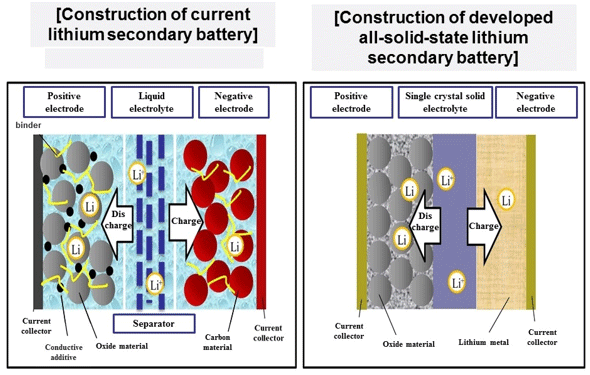

The construction of current lithium secondary batteries (left) and construction of developed all-solid-state lithium secondary battery (right) |

Using the floating zone melting method, the researchers have synthesized the world’s first garnet-type oxide single crystal as a solid electrolyte material. The single crystal has been difficult to synthesize thus far. The single crystal has a dense structure which prevents internal short circuits. By applying the AD method, they also formed a strong interface between an electrode and the solid electrolyte. With this single crystal, lithium ion conductivity equal to or higher than that of organic electrolytic solutions is achieved, which has led to the development of a compact all-solid-state lithium secondary battery with a diameter of 5 mm and a thickness of 0.7 mm.

Although there are various development factors in next-generation lithium secondary batteries, development of solid electrolytes that replace combustible organic electrolytic solutions has been promoted from the perspective of safety. Oxide-type solid electrolyte materials have high chemical stability. However, their lithium-ion conductivity is lower than that of organic electrolytic solutions, gap-free solid electrolyte materials cannot be made, which results in internal short-circuiting caused by penetration of metallic lithium, and the interface between an electrode and a solid electrolyte is weak, practical battery performance had yet to be achieved.

The researchers will continue research and development for the mass production and quality stabilization of the solid electrolyte single crystal manufacturing technology through collaboration with companies. They will also aim for practical application by 2020 in fields of all-solid-state micro battery applications such as medical use through collaboration with related companies.