The Hall coefficient of a bismuth nanowire has been successfully measured using the microfabrication technology combining focused ion beam (FIB) technology and scanning electron microscopy (SEM).

|

|

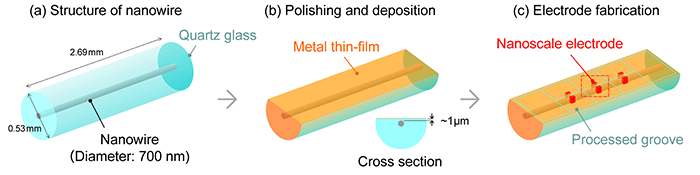

Process for fabricating electrodes on bismuth nanowire in quartz glass |

A bismuth nanowire having a diameter of 700 nm was formed and nanoelectrodes were fabricated on the nanowire using an FIB-SEM apparatus capable of fine processing and observation. Using the fabricated element, a method for accurately measuring the Hall coefficient of a nanowire was developed. The results of measurements provided for the first time experimental verification that carrier mobility was significantly reduced as compared with bulk bismuth.

Nanowire materials are being developed in order to improve the performance of thermoelectric conversion materials. Although it is theoretically proposed that the quantum confinement effect takes place by forming a nanowire structure, and that consequently thermoelectric conversion performance dramatically improves, it is difficult to fabricate wires of nanometer size and also electrically evaluate them because of their nanosize. Accordingly, performance improvement due to the formation of a nanowire structure has not been confirmed. When an accurate Hall coefficient becomes measurable by nanowire fabrication and nanoelectrode formation, carrier mobility as a thermoelectric conversion performance parameter can be known, and therefore the quantum confinement effect can be observed.

The fabrication of bismuth nanowires having even smaller diameters is in progress. Using the electrode fabrication technique developed this time, the reseachers will aim to experimentally observe the effect due to the formation of a nanowire structure.