Recently, harmful chemical substances have been distributed globally causing serious social problems, such as exhaust gas (NOx) from cars, volatile organic chemicals (VOC) responsible to the sick house syndrome, endocrine disturbing chemicals (EDC), and so on. Semiconductor-based photo-catalyst, as represented by titanium oxide (TiO

2), is expected to be a hopeful technology for cleaning the environment, owing to its eco-friendly action and persistent effectiveness in the presence of ultraviolet rays.

The photo-catalyst is suited for breaking down pollutant of very low concentration. As the human olfactory sense is sensitive to airborne odor of trace concentration, the commercialization of air clean-up agent based on deodorant action of photo-catalyst has been advanced to an appreciable level. In the scene of actual application, TiO2 powder is to be fixed by some means. In general, it is coated on a plane such as wall, but this arrangement has a demerit of inadequate probability of coming in contact with pollutant. Under such a circumstance, the ISEM has been engaged in the development of three-dimensional Si/SiC filter to enhance the clean-up efficiency of photo-catalyst by increasing contact probability between catalyst and pollutant.

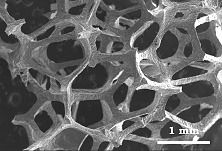

It was found that TiO2 photo-catalyst incorporated into three-dimensional porous ceramics of Si/SiC with similar structure as that of polyurethane sponge ensured efficient decomposition of NOx not only under the irradiation with UV rays but also under the illumination with fluorescent lamp. The 3D photo-catalyst filter was characterized by finer bridge elements, providing high transmittance, enhanced contact probability with pollutant and lower pressure loss. These properties are ideal for a carrier of photo-catalyst.

The conventional ceramic sponge, prepared by coating sponge with ceramic powder slurry and sintering at high temperatures, had rather coarse bridge elements, filling up cells unless the latter are enlarged. On the contrary, porous Si/SiC ceramics retained original geometry of sponge through the reactive sintering of silicon with carbon (Si + C = SiC) followed by melting-impregnation of silicon (Fig. 1). It is possible to prepare porous Si/SiC sponge of ultra-light weight, with bulk density around 0.06 g/cm3 and open porosity as high as 97 %. The cell size is uniform and can be changed at will by replacing the base sponge.

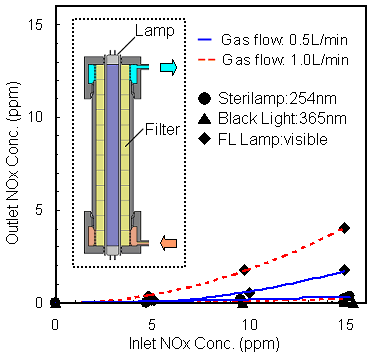

The porous Si/SiC ceramics is characterized by excellent workability, easily fabricated into any shape (Fig. 2) and has high light transmittance, to be suitable as a carrier of photo-catalyst. An experiment to decompose NOx was carried out using a reactor consisting of a series of doughnut-like Si/SiC filters incorporated with photo-catalyst and installed with a 15 W UV or FL lamp at the center. When air containing NOx at a concentration of 15 ppm was fed into the reactor at a rate of 1 L/min, the NOx concentration in the output gas was reduced nearly to 0 ppm through a single session in the presence of UV lamp, such as sterilization lamp or black light lamp, proving the capability of efficient decomposition. Even when a visible FL lamp is used, 15 ppm NOx was reduced to 5 ppm or less (Fig. 3).

|

|

Fig.1. Fine structure of 3D Si/SiC ceramics. |

|

|

|

Fig.2. An outer view of 3D Si/SiC filter.

|

|

|

|

Fig.3. Decomposition of NOx by Si/SiC filter.

|