– Development of fine mold forming technology capable of duplicating nanostructures of biomaterials –

Researchers) TAKEMURA Kenshin, Senior Researcher, MOTOMURA Taisei, attached to the research team, Sensing System Research Center

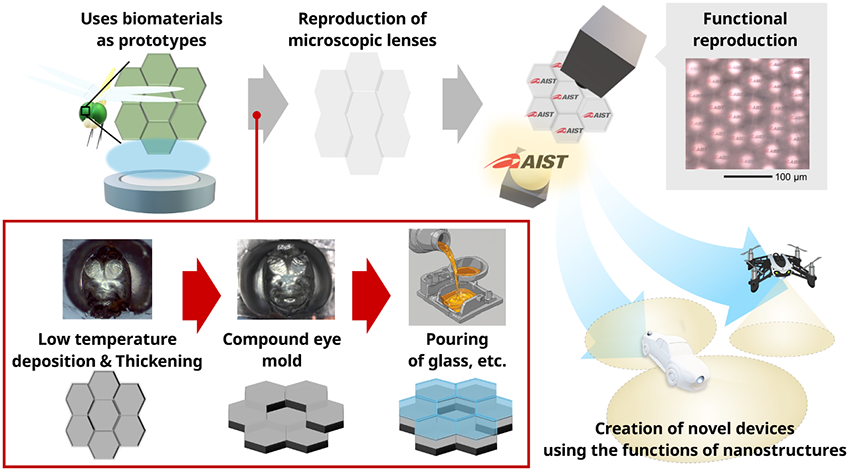

- Development of mold fabrication technology that replicates nanostructures from heat-sensitive materials such as those found in living organisms

- The Fabricated nanostructured molds achieve high heat resistance up to 1000 °C.

- Progress in mass production of nanostructures using fused glass, etc.

Reproduction of functional nanostructures modeled after the compound eye of a dragonfly

* Figures from the original paper have been cited and modified. Creative Commons License (Attribution 4.0 International)

The Nanostructures of living organisms have functions such as super-hydrophobicity and adhesiveness. If these functions could be added to industrial products at will, it would be beneficial to the production of highly-functioning materials. Ultrafine processing using femtosecond lasers has been developed to fabricate nanostructures, and it is now possible to process large areas of simple structures. However, for commercialization through industrial production, a technology to mold nanostructures at a low cost within a short time is required. In addition, thermal damage could occur during mold fabrication, posing a major barrier in the form of material limitations, such as the need for sufficient thermal resistance.

Researchers at AIST have developed a technique to mold nanostructures using a simple process, even from heat-sensitive biomaterials.

Some nanostructures found in living organisms exhibit beneficial functions, such as super-hydrophobicity and adhesiveness, when used in industrial products. Industrial production of highly-functional materials can be realized if these beneficial functions can be imparted to a wide variety of materials by mold forming. However, mold fabrication for nanostructure forming requires advanced equipment and time, making the industrial use of these materials difficult. In particular, a complex process is required to fabricate molds from heat-sensitive materials such as living organisms. In this research, we developed a technology for depositing a sufficiently thick film of high-melting-point metal at low temperature without causing thermal damage to the material. This enables molds to be fabricated from a wide variety of materials, ranging from living organisms to metals.

The dragonfly’s compound eye has more than 20,000 tiny lenses called ommatidia and a 360° wide-angle field of view. It is capable of preventing fogging due to the nanostructures on ommatidia surface. To confirm the effectiveness of this technology, we used the dragonfly’s compound eye as a highly challenging model material and replicated its nanostructure in resin.

We have demonstrated that functionality of the dragonfly’s compound eye can be successfully replicated from a mold. It was also found that the nanostructured mold could be molded by pouring glass, a material with a high melting point. This technology will contribute to the mass production of products that are difficult to reproduce through conventional processing, as well as the industrial production of products with microstructures.

Journal: Advanced Materials Interfaces

Title of paper: Dragonfly-Inspired Compound Eye Lens with Biomimetic Structural Design

Authors: Kenshin Takemura, Taisei Motomura, Wataru Iwasaki, Nobutomo Morita, Kazuya Kikunaga

DOI: 10.1002/admi.202400480