Researchers) IMAI Yusuke, Group Leader, TOMINAGA Yuichi, Senior Researcher, Multi-Material Research Institute, YOSHIDA Masaru, Director, Research Center, TANAKA Shinji, Senior Researcher, Interdisciplinary Research Center for Catalytic Chemistry, National Institute of Advanced Industrial Science and Technology (AIST)

TAGUCHI Seiichi, Professor, KOH Sangho, Assistant Professor, Kobe University

- Blending plastic materials that are biosynthesized by microorganisms with polylactic acid promotes the biodegradation of polylactic acid in seawater.

- The blend also significantly improves the elongation of polylactic acid.

- Contributing to the promotion of plastic materials derived from bioresources.

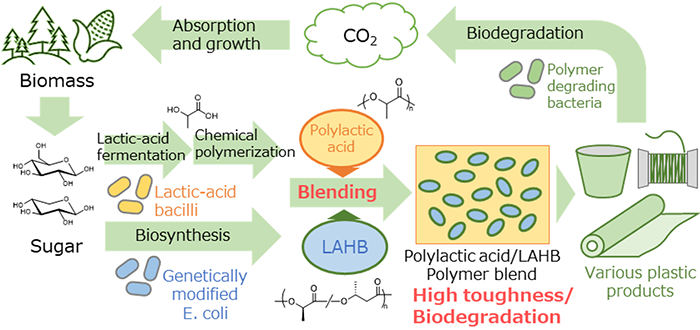

Circular bio-derived plastic materials for which this research aims

Synthetic plastics, manufactured from fossil resources such as petroleum, are widely used as materials that support modern life, with approximately 10 million tons produced annually in Japan and 400 million tons worldwide. On the other hand, environmental pollution caused by plastics leaked into the environment has become an issue. In addition, because plastics are made from fossil resources, they contribute to the increase in carbon dioxide concentration, which is a cause of climate change.

Since biodegradable plastics break down over time to water and carbon dioxide, their expanded use will help reduce environmental pollution. In terms of reducing consumption of fossil resources, substitution of plastics with plastics made from bio-derived resources that fix carbon dioxide in the atmosphere is effective.

One such plastic material is polylactic acid (PLA). PLA is a bioplastic material synthesized through chemical polymerization using lactic acid, obtained through lactic acid fermentation of bio-derived resources, as the monomer. PLA exhibits physical properties comparable to those of polypropylene and polyethylene terephthalate (PET) and is expected to expand its use as an alternative to petroleum-based plastics due to its transparency and biocompatibility. However, PLA has problems such as being hard to stretch, brittle, and biodegradable only under limited environmental conditions, which have hindered the expansion of its use.

Researchers at AIST and Kobe University, in collaboration with KANEKA Corporation, have overcome the brittleness and biodegradability challenges of PLA by blending a copolymer of lactic acid and 3-hydroxybutanoic acid (LAHB for short), which is biosynthesized by microbes.

PLA is a typical bioresource-derived plastic, but it is mechanically brittle and has limited biodegradability. By blending LAHB with PLA, we have succeeded in significantly improving the elongation of PLA. We have also found that LAHB blending promotes the biodegradation of PLA in seawater.