Researchers) TANAKA Shinji, Senior Researcher, NAKAJIMA Yumiko, Team Leader, Silicon Chemistry Team, Interdisciplinary Research Center for Catalytic Chemistry

- Development of catalytic reaction that efficiently converts PET resins into raw materials at ambient temperature

- A newly developed method successfully lowers the reaction temperature for the recovery of raw material from the previous about 200 °C to ambient temperature

- Expected to reduce the "bottle to bottle" recycling cost of PET bottles

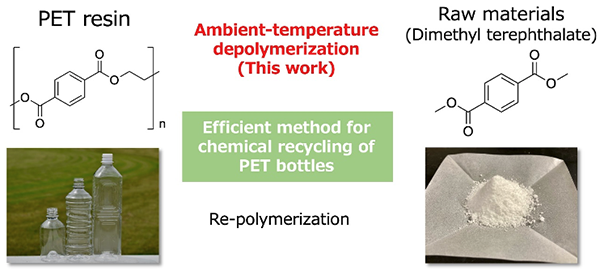

Outline of efficient PET bottle recycling method using our approach

The issue of environmental pollution by plastic garbage is increasingly attracting attention. As such, development of basic technology for efficiently recycling plastic products used by society is becoming an urgent matter. Polyethylene terephthalate (PET) resin is a plastic material that is widely used in modern society as food bottles and fibers. Mechanical recycling and chemical recycling are known as recycling methods for recovered PET resin. The mechanical recycling method melts, and reforms used PET materials as a resin form after sorting, but the influence of impurities makes it a challenge to keep the quality after the recycling. Chemical recycling, on the other hand, chemically depolymerizes PET resin into monomers, which in principle enables fabrication with the same quality as the original PET product. However, this method had the major issues of requiring a high temperature for the depolymerization process and being a costly process. The ability to recycle repeatedly is demanded from the perspective of Sustainable Development Goals (SDGs). Chemical recycling that does not lower the quality holds promise in that respect, and various approaches to reduce the depolymerization temperature in particular are being actively studied.

Researchers in AIST developed a catalytic process for converting PET resin in used PET bottles into dimethyl terephthalate at ambient temperature with high yield and high purity.

This technology utilizes an alkaline catalyst with dimethyl carbonate to efficiently depolymerize PET resin at ambient temperature in a short reaction time. It enables to recover the raw material, dimethyl terephthalate, in more than 90 % yield. The reaction temperature can be significantly lowered from that of the conventional method processing at about 200 °C. This technology potentially reduces the cost of bottle-to-bottle recycling.