– Development of a portable air-cooled thermoelectric generator that does not require cooling water –

Power generation output decreased to 1/3 as a result of converting a conventional water-cooled thermoelectric power generator to air-cooling. So AIST developed a heat pipe system that enables high output power generation, increased the output of each thermoelectric element, and improved the cross-sectional area and arrangements of the elements. Thus AIST has developed a practical air-cooled thermoelectric generator that is mass-producible.

|

|

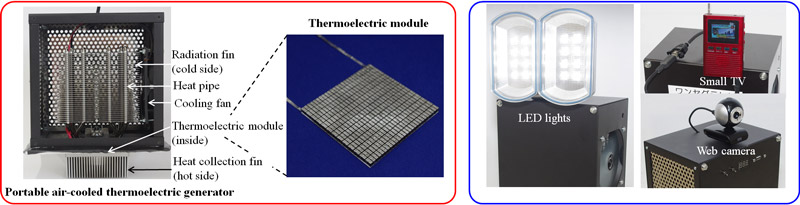

The developed portable air-cooled thermoelectric generator and the thermoelectric module (left) and examples of electronic devices operating on the thermoelectric generator (right) |

In order to increase the power generation output of the air-cooled thermoelectric generator, the researcher has developed the following technologies. First, technology that refines the control of the sintering process under pressure was developed to improve the power factor of the thermoelectric element by two-fold. Second, decrease in the cross-sectional areas of each element was found to be effective to reduce the internal resistance of the module by 20 %. With these two technologies, total power generation output was increased 2.2 times. By using the improved heat pipe, the decrease in temperature difference was reduced, and power generation output equivalent to 80 % of the water-cooled thermoelectric generator was achieved.

AIST has developed technology to produce calcium cobalt oxide, a p-type thermoelectric material with high conversion efficiency, as well as calcium manganese oxide, an n-type thermoelectric material, and has produced and demonstrated a water-cooled thermoelectric generator. However, industry demands an air-cooled thermoelectric power generator which is structurally simple and can be miniaturized, so AIST worked on the development of an air-cooled generator comparable to water-cooled generators.

AIST will conduct demonstration tests of the developed power generator, and practicalize it within 2 years for recovery of exhaust heat from industrial furnaces and incinerators, and as an emergency power supply. In addition, AIST will develop new thermoelectric materials and thermoelectric modules that are superior in performance, durability, safety, and cost, and contribute to energy conservation, reduction of carbon dioxide emission, and creation of new industries.