– Contributing to the improvement of temperature measurement and control at high temperatures –

Widiatmo Januarius (Senior Researcher), Thermometry Research Group, the Research Institute for Physical Measurement (Director: Yasuhiro Nakamura) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), in collaboration with Chino Corporation (President and Representative Director: Takao Kariya), has developed a platinum resistance thermometer that can precisely measure temperature at around 1000 °C.

Platinum resistance thermometers equipped with platinum wire in their sensors are used when precise temperature measurement is necessary, such as in semiconductor manufacturing. However, at high temperatures near 1000 °C, the resistance value of the platinum wire becomes unstable, and thermal strain occurs in the platinum wire due to high temperature, causing it to become even more unstable, and making precise measurement of high temperatures difficult.

By heat-cycling tests employing the AIST national standard (temperature standard), the platinum wire of the sensor was examined in detail to find optimum conditions for stabilizing the resistance value. As a result, it was found that when an appropriate thermal treatment is applied to the platinum wire, the resistance value is stable even at high temperatures around 1000 °C. Furthermore, a new sensor structure was devised, which reduces thermal strain that occurs in the platinum wire at high temperatures. From these findings, a new platinum resistance thermometer capable of temperature measurement at the 0.001 °C level of precision even at high temperature was developed. This thermometer has a bright prospect of highly precise temperature measurement and temperature control at high temperature, such as in materials processing.

Details of this technology will be presented at the international conference TEMPMEKO 2016 held in Poland from June 27 to July 1, 2016.

|

|

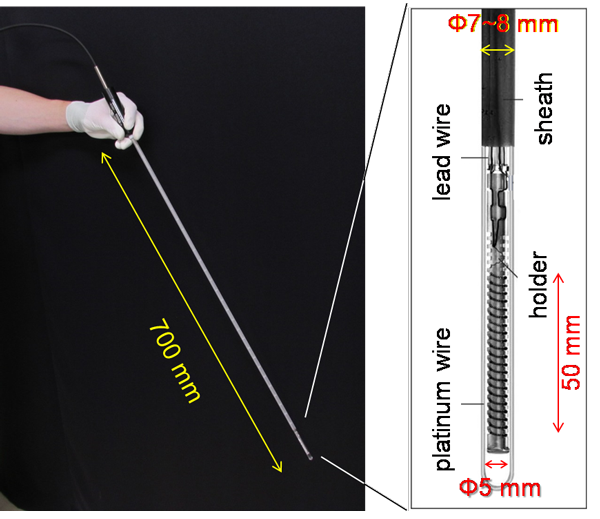

Appearance of the newly developed platinum resistance thermometer (left) and sensor at the tip (right) |

In the field of industry, high-precision temperature measurement is necessary for manufacture, quality control, and safety management. In particular, platinum resistance thermometers with platinum wire in their sensors are used for temperature measurement at the 0.01 °C level of precision. However, at high temperatures around 1000 °C used for thermal processing of material such as silicon wafers and metals, the measured value changes due to heat strain that occurs in the sensor of the platinum resistance thermometer. For this reason, precise temperature measurement with high reliability at high temperature is difficult.

To use platinum resistance thermometers capable of highly precise temperature measurement even at high temperatures near 1000° C, it is necessary for the platinum wire of the sensor to have a stable resistance value. AIST has conducted research and development of a system that realizes the triple point of water (0.01° C) and the silver freezing point (961.78° C), which are used as international temperature standards and are temperatures with extremely high reproducibility, as the national standards for temperature in Japan. AIST has also conducted development of high-precision temperature sensors and research and development of technology to evaluate sensors. Chino Corporation is one of the leading thermometer manufacturers in Japan, and possesses manufacturing technology for highly precise thermometers.

In recent years, due to the sophistication of manufacturing, the need for high-precision temperature measurement at high temperatures is even greater than before. Therefore, AIST and Chino Corporation decided to develop a platinum resistance thermometer capable of highly precise measurement at temperatures around 1000 °C.

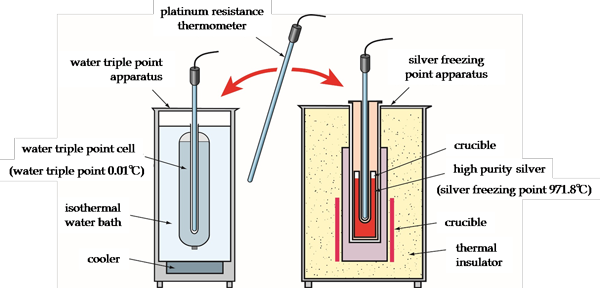

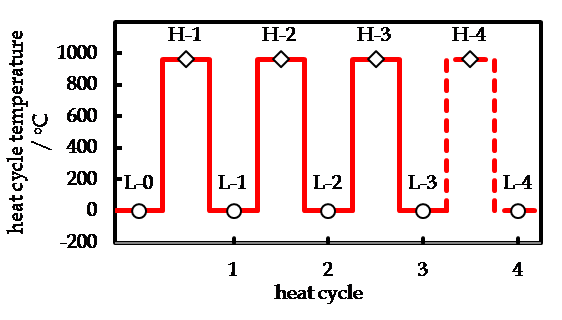

In this study, several conventional platinum resistance thermometers were purchased, and moderate heat treatment was carried out. Then, AIST conducted heat cycle tests (Fig. 1) which measure the resistance value of the platinum resistance thermometers by repeatedly inserting them into the national standard apparatuses for realizing the triple point of water and the silver freezing point to examine changes in the resistance value at various temperatures.

|

|

Figure 1: Heat cycle test using a triple point of water apparatus and a silver freezing point apparatus (top) and temperature profile in heat cycle (bottom) |

From these results, it was found that if this heat treatment is conducted during the sensor preparation process, changes in resistance value are minimized at temperatures around 1000° C, and it is possible to produce stable thermometers. To reduce the heat stain that occurs in the sensing platinum wire when platinum resistance thermometers are used at high temperature, a new structure for the holder of the platinum wire was proposed. Applying this new structure and the thermal treatment effect, platinum resistance thermometers were developed.

|

|

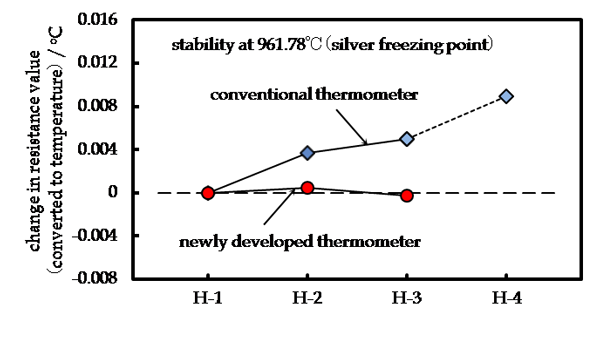

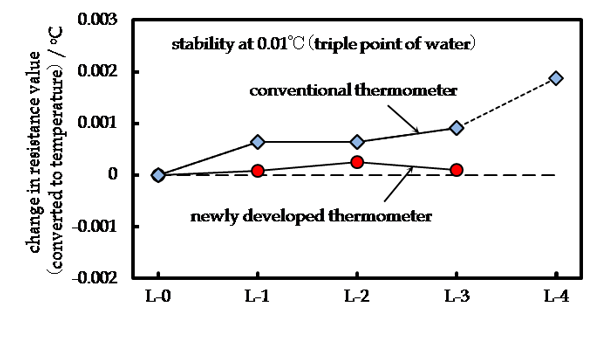

Figure 2: Results of evaluation of platinum resistance thermometers at the silver freezing point and the triple point of water |

Fig. 2 shows the change in resistance value of the sensors converted to temperature, having conducted heat cycle tests with the triple point of water 0.01° C and the silver freezing point 961.78° C, for a conventional thermometer and the newly developed thermometer. In practice, this test was performed on three cycles. With the conventional thermometer, the resistance value at 961.78 °C tends to increase each time a heat cycle was added, and the total increase after the additional 4th cycle was about 0.01 °C. On the other hand, that with the newly developed thermometer was stable within ±0.001 °C. Furthermore, resistance value changes at the triple point of water 0.01° C also tended to rise in conventional thermometers, but the newly developed thermometer stabilized within ±0.0005° C. These results demonstrated that the newly developed platinum resistance thermometer can be used repeatedly at high temperatures around 1000° C with extremely small variation of resistance values, and highly reliable, high-precision temperature measurement is therefore possible.

The stability of the newly developed platinum resistance thermometer against heat cycle tests is of the world’s top level. In the future, it can contribute to the realization of high-precision temperature measurement and temperature control at high temperatures, such as in materials processes. Mutual comparisons of temperature standard near 1000 °C are carried out among various national metrology institutes, each of which maintains the temperature national standard of its own country. The newly developed thermometer can also play a very important role in such a world top-level comparison.

In the future, Chino Corporation will continue evaluating the long-term stability of the newly developed platinum resistance thermometer, while also working towards its commercialization. Additionally, AIST plans to advance research and development of highly precise thermometers at temperatures exceeding 1000° C, based on this thermometer.