Update(MM/DD/YYYY):03/18/2016

Development of High-frequency Transmission Lines with Excellent Transmission Properties in the Millimeter-wave Band

– Affordable realization of highly accurate performance evaluation of millimeter-wave band devices –

Points

-

Development of transmission lines with excellent transmission properties for high frequencies exceeding 100 GHz

-

Realization of shorter production time and lower costs by utilizing printing technology

-

Usable as a “standard transmission line” for performance evaluation of millimeter-wave band devices

Summary

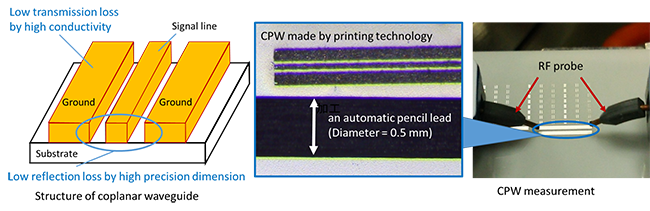

Masahiro Horibe (Senior Researcher) of Radio-Frequency Standards Group, the Research Institute for Physical Measurement (Director: Yasuhiro Nakamura), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), and Manabu Yoshida (Leader) of Printed Electronics Device Team, the Flexible Electronics Research Center (Director: Toshihide Kamata), AIST, have developed a high-frequency transmission line (a coplanar waveguide) that shows excellent transmission properties in the millimeter-wave (MMW) band exceeding 100 GHz, by utilizing printing technology.

A coplanar waveguide (CPW) line with highly conductive conductor in conducting body and better measurement accuracy was fabricated by employing printing technology which uses highly conductive silver nanoparticle ink. This CPW line displayed low loss at the high frequency band exceeding 100 GHz. In particular, it suffered a transmission loss of only about half that of conventional CPW lines at 60 GHz or higher. Because property degradation due to repeated use is lower, it can also be used as a “standard transmission line” for evaluating the electrical performance of MMW band devices. Additionally, by employing screen printing technology that can form many patterns at once, shortened manufacturing time and lower costs were achieved compared to conventional manufacturing methods which employ conductive film deposition, photolithography, and etching. (Manufacturing time: approx. 1 hour*1, less than 1/20 of conventional methods. Manufacturing Cost: approx. ¥6,000*1, less than 1/10 of conventional methods.)

The details of the developed technology will be presented at European Microwave Week 2015 (EuMW2015) to be held in France, on September 9, 2015.

*1: Calculation made from costs required for the fabrication including supplies, labor, and utilities costs, indicating the cost for one substrate on which thirty to forty standard transmission lines were fabricated.

|

CPW line fabricated using printing technology

MMW band electromagnetic waves exceeding 100 GHz can be transmitted. |

Social Background of Research

Electromagnetic waves at the millimeter-wavelength region, over 30 GHz, have the advantages of being able to measure distance at high resolution and transmit a large volume of data at high speed. Until now, the spread of devices using the MMW band (MMW band devices) was impeded by their high cost, but in recent years affordable silicon devices have become able to operate on the MMW band, and the development of MMW band devices including automotive collision avoidance radar, near field radio communication, and 5th generation (5G) mobile phone systems, is advancing. Along with this, “standard transmission lines” used for performance evaluation of MMW band devices are gaining importance. Standard transmission lines are required to have stable properties even after long periods of use. However, because measurement is performed by contacting high frequency probes to standard transmission lines, repeated use changes the state of the contact points, causing degradation of the transmission and reflection properties. Therefore, in order to make highly accurate performance evaluation of MMW band devices, it is necessary to frequently*2 replace expensive standard transmission lines (costing tens of thousands to hundreds of thousands of yen*3), meaning there is need for affordable standard transmission lines that suffer little degradation due to repeated use.

*2: The replacement of the standard transmission line is needed after using it ten times or so and the substrate needs to be replaced after it has been used about 300 to 400 times, which differs depending on the use conditions.

*3: Thirty to forty standard transmission lines have been manufactured on a single substrate and the cost per substrate was shown.

History of Research

AIST conducts research and development of performance evaluation technology for MMW band devices. Standard transmission lines with excellent loss and reflection properties are necessary to conduct highly accurate performance evaluation at the MMW band. Furthermore, it is necessary to make replacement of standard transmission lines easy by reducing the cost in order to continuously implement highly accurate evaluation of device performance.

AIST also performs research and development with the aim of realizing printed electronics, and is currently working on the development and advancement of printing processes suitable for the formation of electronic devices by printing methods. Therefore, AIST has decided to carry out research and development to affordably manufacture high performance, high-frequency transmission lines using printing technology.

Details of Research

Because the transmission and reflection properties of CPW lines are determined by the conductivity of the conductor and the dimensional accuracy of the CPW lines, high conductivity and manufacturing technology with high manufacturing precision are needed to manufacture high performance CPW lines. In this research, AIST has designed a MMW band CPW line capable of transmitting signals of up to 110 GHz. Employing highly conductive silver nanoparticle ink and high-definition screen printing technology, AIST has fabricated a CPW line (signal line width of 50 µm, distance between the signal line and the ground line of 25 µm) on an alumina substrate.

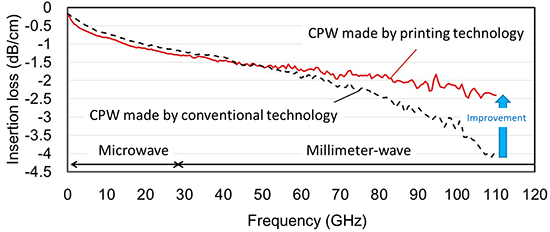

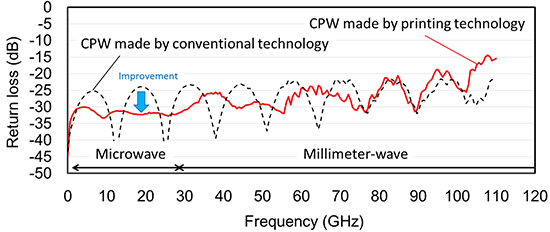

The transmission and reflection properties for signals up to 110 GHz were evaluated for both the newly developed, printed CPW lines and a conventional CPW line (Fig. 1 a, b). Transmission properties value closer to zero means lower loss, namely higher performance. The printed transmission line has performance equal to or higher than that of the conventional transmission line. In the high frequency range above 60 GHz, the printed CPW line has even lower loss than the conventional CPW line and achieves about half loss at frequencies over 100 GHz. Smaller reflection properties value means lower reflection of signal, namely higher performance. The developed waveguide also showed nearly equivalent performance with the conventional waveguide in terms of reflection properties. These evaluation results show that transmission lines with conductivity and manufacturing accuracy equal to or better than those of conventional ones can be manufactured with printing technology.

|

(a) |

|

|

(b) |

|

Figure 1: Evaluation results of the high-frequency electrical properties of CPW lines

(a) Transmission properties (b) Reflection properties |

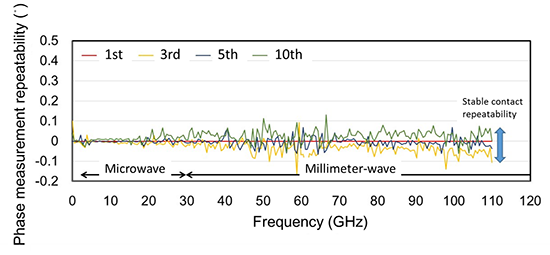

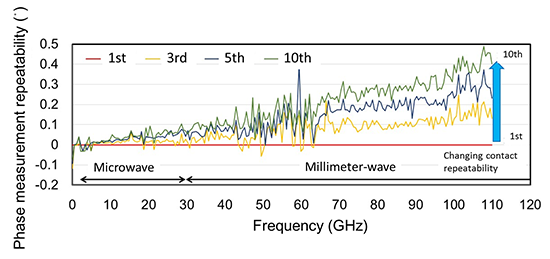

In order to use high-frequency transmission lines as standard transmission lines, it is necessary to be capable of keeping their properties stable even after contacting them repeatedly with high-frequency probes. The developed CPW line was contacted 10 times with high frequency probes, and when the phase change of the transmission properties was measured (Fig. 2 a, b), it was found that the CPW line manufactured by the printing method had increased stability, with a phase change only 1/3 that of the conventional CPW line. This is presumably because the deformation of the conductive metal surfaces due to repeated contact is smaller.

From these evaluation and measurement results, it is clear that the developed CPW line has transmission properties and stability superior to those of conventional CPW lines and can be used as a standard transmission line. Additionally, because of the affordable manufacturing cost, it is very promising as a “standard transmission line” for the performance evaluation of MMW band devices.

|

(a) |

|

|

(b) |

|

Figure 2: Results of stability evaluation of the properties of CPW lines against repeated contact with high frequency probes

Reproducibility of the phase measurement results of transmission lines (normalized by the first measured value) (a) Printing technology (b) Conventional technology |

Future Plans

The researchers plan to use the developed CPW line for performance evaluation of various MMW band devices, and demonstrate its usefulness as a “standard transmission line”.