Atsushi Hozumi (Leader) and Chihiro Urata (Researcher), the Durable Materials Group, the Materials Research Institute for Sustainable Development (Director: Mamoru Nakamura), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), have developed a surface processing technology which can substantially suppress the adhesion of a variety of viscous liquids and ice.

At present, most liquid (water and oil) repellent processing depends on processing by organic fluorine compounds or micro-fabrication of the surface. However, organic fluorine compounds have high production and disposal costs, and micro-fabrication requires special equipment and long machining time. Therefore, there is a need for an inexpensive liquid repellent processing technology which does not depend on the organic fluorine compounds or micro-fabrication.

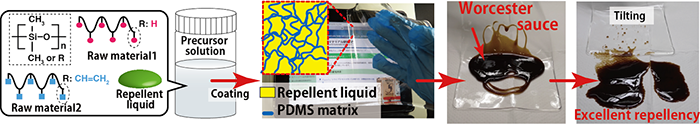

The developed liquid repellent processing technology utilizes the phenomena known as syneresis and blooming observed in resin and gel. When forming the gel containing liquid repellent ingredient on a solid surface, a thin layer is formed by spreading the liquid repellent ingredient from the gel onto the surface by syneresis; the surface will then exhibit superior liquid repellent characteristics. Liquids lacking affinity for the liquid repellent layer cannot adhere to the surface and slide down smoothly, even in the case of viscous liquids. This processing technology does not require special equipment or reaction conditions, and enables processing merely by applying the coating liquid. After processing, the surface is transparent and can be prepared for a large area (A4 size).

Since the suppression of adhesion of various viscous liquids, and the reduction of ice adhesion, can be obtained using the developed surface processing technology, it has potential applications for surfaces where viscous liquids and ice are likely to adhere, such as packaging containers, metal molds, the bottom of ships, water intakes, and building materials. Design preservation, cost reduction, reduction in energy consumption, simplification of maintenance, and improvements in safety and reliability are expected.

A part of this technology will be presented at the 3rd Nature Industry Award to be held on December 12, 2014 at Osaka Science and Technology Center (Osaka city, Osaka) and at the AIST booth of the 14th Nanotechnology International Exhibition & Conference (NanoTech 2015) to be held on January 28-30, 2015 at Tokyo Big Sight (Koto-ku, Tokyo).

|

The developed surface processing technology and the liquid repellent property

(Worcestershire sauce has been used as a model viscous liquid) |

In our country, which is poor in energy and natural resources, the demand for new materials and manufacturing processes that can contribute to savings in energy and natural resources is high. Since droplets adhered to solid surfaces cause damage to packaged items, surface corrosion and deterioration, degradation in appearance, lower visibility, increases in flow resistance, and significant loss of the safety and reliability of equipment and apparatus, basic and applied researches in surface processing technology with superior droplet removal performance and adhesion prevention are increasing. However, most conventional surface processing technologies depend on surface processing by organic fluorine compounds or surface micro-fabrication. In order to manufacture a liquid repellent surface simply, and at low cost, a surface processing technology independent of these complex processes is in high demand.

AIST has been working on the development of surface reforming technologies that show excellent liquid repellent characteristics using simpler methods than those which require organic fluorine compounds and surface micro-fabrication. So far, it has been found that a transparent coating film made from alkyltrialkoxysilane, a common liquid repellent processing agent, and tetraalkoxysilane, a raw material of glass, has excellent oil repellency (AIST press release on March 13, 2012). In addition, a transparent coating film having both heat-resistance and oil repellency has been developed. The coating film utilizes the heat-resisting properties of methylsiloxy unit by using methylsilane as a primary raw material (AIST press release on September 10, 2013). However, while the surfaces of these coating films showed excellent liquid repellent characteristics against pure liquids (water and oils such as n-hexadecane), the films are not effective against viscous liquid such as mayonnaise and sauce. Furthermore, once ice formed on the coating film surface it was difficult to remove, due to strong adhesion of the ice to the surface. Therefore, the researchers have worked on the development of a surface processing technology with a suppressing effect against viscous liquid adhesion, and reduction of the adhesive strength of ice.

A part of this research and development was implemented under the support of Grants-in-Aid for Scientific Research (new academic field study) (24120005) by the Ministry of Education, Culture, Sports, Science and Technology.

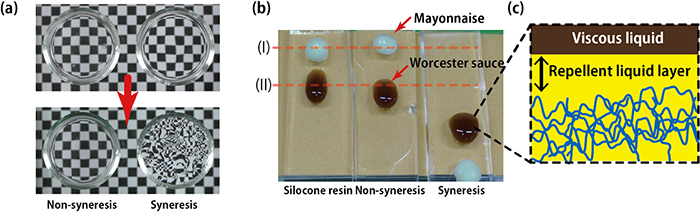

The developed surface processing technology utilizes a phase separation phenomenon known as syneresis, observed in gels and resins. Due to the degradation in appearance of the products, suppression of syneresis and blooming has been the focus of most research so far. In this study, the researchers have utilized and controlled the phase separation phenomenon positively, and formed a thin layer of expelled, liquid-repellent liquid on the surface and, realized surface processing that is superior in terms of high sticking resistance. In this surface processing, polydimethylsiloxane (silicone resin), which is superior in flexibility and transparency, is used as the solid matrix. A silicone resin, a liquid-repellent liquid, and a catalyst are mixed, applied to the surface, and cured to form the coating film. The solid surface was transparent immediately after the fabrication, and syneresis of the liquid-repellent liquid was observed over time (Fig 1a). Various viscous liquids (such as seasonings, e. g. mayonnaise and sauce) slid down smoothly from surfaces where a thin layer of liquid-repellent liquid had been formed. Conversely, on surfaces of pure silicone resin without the repellent liquid, and gels which did not show syneresis, the viscous liquids described above adhered strongly (Fig 1b, c).

|

Figure 1: (a)The developed syneresis gel and the gel containing liquid repellent ingredient which doesn’t show syneresis

(b) Liquid repellent characteristics of the syneresis gel (each test sample at the tilt of approximately 20 °, and (I) and (II) indicate dropping positions of mayonnaise and sauce, respectively.)

(c) Schematic illustration of liquid repellent mechanism |

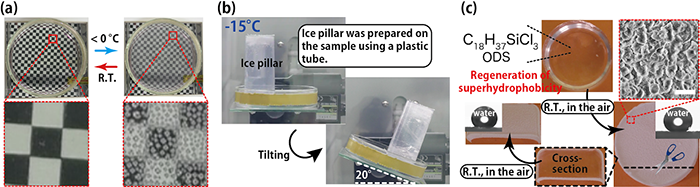

When precisely controlling the affinity of silicone resin and the liquid-repellent liquid, the syneresis behavior showed temperature dependence. In the wet gel shown in Fig 2a, syneresis did not occur at room temperature, but was observed below the freezing point, and this change was found to be reversible. Since the adhesion of ice was very low on the surface, icicles frozen on the gel surface (adhered ice) slid down, even with a low tilt (Fig. 2b). In short, syneresis only occurs in the gel during cold periods of snow, and the wasteful outflow of the liquid-repellent liquid by syneresis could be prevented during milder periods.

When octadecyltrichlorosilane (ODS), which reacts with water and forms the super water repellent surface spontaneously, was used as the liquid-repellent liquid, ODS molecules are expelled by syneresis and gradually reacted with the water molecules in the air to form a concave-convex structure, like a lotus leaf, on the gel surface (Fig 2c). This surface had a contact angle of more than 150° for water droplets, and showed super water repellent characteristics, similar to lotus leaves. Since the internal cross-sectional area was as transparent as before the gel was cut, it was found that only the expelled ODS molecules reacted with the water in the air. Furthermore, since the cut surface gradually whitened and showed super water repellent characteristics when kept in air, the gel was found to have a self-recovery function.

|

Figure 2: (a) Photos of reversible control in syneresis by temperature

(b) Photos of sliding ice on the surface of the temperature dependent syneresis gel (The block of ice was made in a cylindrical container.)

(c) The spontaneous forming of the super water repellent surface of the gel containing ODS and its self-recovery (scale bar:10µm). |

The greatest advantage of the developed surface processing technology is the excellent sticking resistance characteristics shown against a variety of viscous liquids, and ice. Furthermore, due to its excellent transparency, it has possible applications in a wide variety of areas, such as agriculture, fisheries, construction, and civil engineering, as well as in packaging. For instance, because seaweeds, barnacles, etc. tend to cling to water intakes of power plants and the bottom of ships, degradation of thermal conductivity and increase of flow resistance occur, causing major energy loss. Using the developed surface processing technology, the suppression of the adherent of these creatures can be expected. Additionally, since this can substantially reduce the adhesion of ice and snow, it can be applied to the prevention of greenhouse corruption due to snow accumulation, house maintenance in heavy snow fall areas, reduction of danger caused by snow and ice falling, the safe operation of trains and airplanes, and measures against snow damage.

By collaborating with companies, the researchers aim to implement the developed technology within three years, having cleared issues such as selection and optimization of gel components suitable for usage and materials, safety testing, improvements in hardness, and exploring coating methods for mass production.