- A lightweight, sturdy viscoelastic material for use in a wide range of temperatures -

Kenji Hata (Prime Senior Researcher), the Nanotube Research Center (NRC; Director: Sumio Iijima) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi) and Don Futaba (Senior Researcher), Super Growth CNT Team (Leader: Kenji Hata), NRC, AIST, together with Xu Ming (Postdoctoral Researcher) of the Technology Research Association for Single Wall Carbon Nanotubes (TASC), have produced high-purity carbon nanotubes (CNTs) with a random network structure by applying the super growth technique. This CNT structure exhibits rubber-like viscoelasticity in a temperature range of -196 to 1000 °C.

Viscoelastic materials are used as shock and vibration absorbers. Most of them are polymers and lose their viscoelastic properties at very low and high temperatures, and their viscoelasticity has frequency dependence. They have low durability, being susceptible to cyclic stress-induced degradation and damage.

The new CNT viscoelastic body is lightweight, with a density of 0.036 g/cm3, and exhibits viscoelasticity in a temperature range of -196 to 1000 °C. It shows frequency-independent, stable viscoelasticity in a frequency range of 0.1 to 100 Hz at temperatures of -140 to 600 °C. When subjected to one million cycles of 1% torsional strain at 100 Hz, the body did not degrade or break. It has potential for use in shock and vibration absorbers at very low and high temperatures.

Details of this study will be published in Science, a US scientific journal, on December 4, 2010 (JST).

|

|

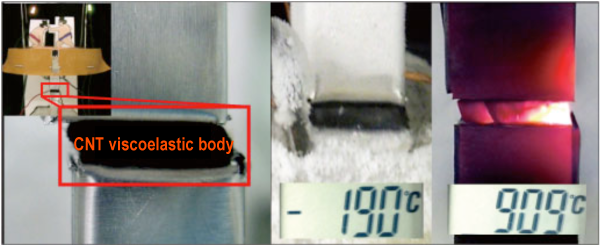

Photos Vibration isolation device using a carbon nanotube viscoelastic body (left) The device retains its vibration isolation capability when cooled with liquid nitrogen (middle) or heated with a burner (right). |

Viscoelastic bodies are used widely to absorb shock and reduce vibration in consumer goods, such as shoe soles and bedding, vibration control systems for vehicles, industrial vibration isolation systems, and seismic isolation systems for buildings. However, most of these materials are polymers such as rubber. Even silicon rubber, the most temperature-stable viscoelastic material, hardens at a low temperature (about -55 °C) and decomposes at a high temperature (about 300 °C), losing the properties of a viscoelastic body. Cyclic stress results in a decrease in energy-absorbing capability and eventually causes breakage. Because of this, viscoelastic bodies need to be developed that can absorb shock and reduce vibration under severe conditions.

Use of the super growth technique allows the synthesis of high-purity, very long (longer than a few hundred micrometers) CNTs. These CNTs do not contain catalytic particles and therefore do not oxidize at a high temperature, and they have sufficient mechanical strength because of their great length. AIST is conducting research to control the microstructure of CNTs more precisely by improving catalysis preparation methods.

Because of their known strength, elasticity, and temperature stability, CNTs are attracting attention as structural materials. The fatigue strength and compressive elasticity of various CNT structures, including oriented CNTs, CNT films, and fibrous CNTs, have been studied. However, there have been no studies of the viscoelasticity of CNT structures. AIST and TASC have successfully synthesized a network structure of intertwined CNTs by using the reactive ion-etching technique to prepare the catalyst, and have studied the viscoelasticity of this structure.

This study was conducted as part of the projects of Tsukuba Innovation Arena being undertaken by AIST and other organizations.

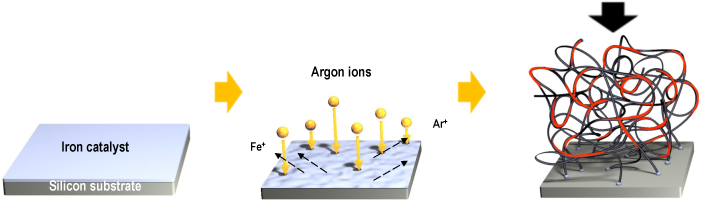

CNT viscoelastic bodies were synthesized by using the following procedure (Fig. 1). An iron catalyst was applied to the silicon substrate by spattering. The catalyst was then prepared by reactive ion-etching with argon ions. The CNTs were synthesized on the substrate by the super growth technique. The synthesized CNT structure was then compressed to increase the density fourfold. The size of the structure after compression was 10 ×10 × 2 mm and the density was 0.036 g/cm3.

|

|

Figure 1 Schematic of the procedure used to synthesize CNT viscoelastic bodies |

A steel ball was dropped onto the CNT viscoelastic body and the shape of the indentation was observed under a laser microscope. There was no change in shape at temperatures of -196, 25, and 1000 °C. This suggests that the material exhibits viscoelasticity in a wide range of temperatures.

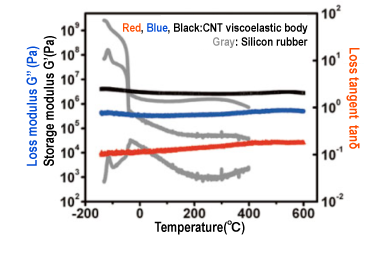

The storage modulus, loss modulus, and loss tangent of the body were measured by dynamic mechanical analysis (DMA) in a temperature range of -140 to 600 °C to quantitatively evaluate the properties of the viscoelastic body. The values obtained were nearly constant over the temperature range (Fig. 2). The area enclosed by the stress–strain curve measured at 25 °C was larger than that of silicon rubber, showing that more energy was absorbed.

|

|

Figure 2 Temperature dependence of the loss modulus, storage modulus, and loss tangent of the CNT viscoelastic body and of silicon rubber measured by the DMA technique |

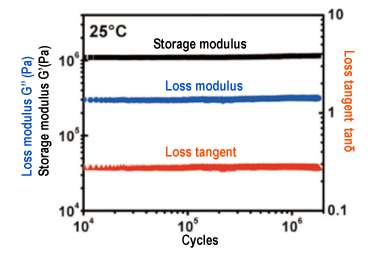

Frequency dependence over a frequency range of 0.1 to 100 Hz was measured in a temperature range of -140 to 600 °C. The measurements showed viscoelasticity independent of both temperature and frequency. The critical strain, the maximum strain of reversible deformation, was 5% over a temperature range of -140 to 600 °C, independent of the temperature, and the breaking strain at room temperature was about 100%. A durability tests were performed by applying one million cycles of 1% torsional strain to the CNT viscoelastic bodies at -140, 25, and 600 °C. The tests showed no change in storage modulus, loss modulus, or loss tangent at all temperatures.

The possible reason for the temperature- and frequency-independent viscoelasticity over a wide range of temperatures and frequencies and high fatigue durability of the CNT viscoelastic body is that the long CNTs are intertwined to form a low-density network structure. The strain energy is absorbed when the intersections of the CNTs in the network structure change from a contact state to a separate state. The absorbed strain energy is converted to heat. If the heat is stored in the viscoelastic body, the performance of the body deteriorates. However, because of its high porosity and heat conductivity, the CNT viscoelastic body dissipates the heat efficiently and, consequently, exhibits stable viscoelasticity.

|

|

Figure 3 Results of testing in which the CNT viscoelastic body was subjected to one million cycles of torsional strain at 25 °C |

The newly developed CNT structure has the potential for use as a very lightweight viscoelastic material that can absorb shock and vibration energy at very low and high temperatures. It will be further developed as part of “the Project to Develop Ultra-lightweight, High-strength Composite Materials toward a Low Carbon Society” commissioned by the Industrial Science and Technology Policy and Environment Bureau of the Ministry of Economy, Trade and Industry. Samples will be provided to the private sector to jointly develop uses of the material.