Yoshiro Yamada (Senior Research Scientist) and Juntaro Ishii (Section Chief) of the Radiation Thermometry Section, Temperature and Humidity Division, the Metrology Institute of Japan (Director: Masahiro Okaji) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Tamotsu Nomakuchi), have developed a surface temperature monitoring system for the high-speed optical-annealing of silicon wafers (flash lamp annealing), in collaboration with Semiconductor Leading Edge Technologies, Inc. (Selete) (President: Hisatsune Watanabe), Dainippon Screen Mfg. Co., Ltd. (SCREEN) (President: Masahiro Hashimoto), and CHINO Corporation (CHINO) (President: Takao Kariya).

The developed system enables contactless, precise, and rapid measurement of changes in the wafer surface temperature, which reaches around 1000 °C. The system eliminates the influence of strong light emission from xenon lamps for heating, as well as that of the behavior of the emissivity of the wafer surface. When installed on a flash lamp annealing apparatus, this surface temperature monitoring system can be used for in situ measurement of the temperature of the wafer surface; the temperature increases and decreases rapidly within a period as short as 0.001 s. This technology will contribute to the sophistication of silicon device miniaturization and is expected to be adopted for temperature monitoring in various high-temperature processes in industry.

Details on this technology will be presented at the "2009 International Conference on Solid State Devices and Materials (SSDM 2009)" to be held in Sendai on October 7-9, 2009.

|

|

Overview of the flash lamp annealing system and temperature monitoring system |

It is considered necessary to upgrade rapid thermal annealing (RTA) technologies for activating implanted dopants and controlling diffusion of impurities, as technologies for the increased miniaturization of silicon devices. For example, in the flash lamp annealing method, a cutting-edge RTA method, the wafer is treated by a process in which the temperature is increased to almost 1300 °C (and then decreased) in as short a period as about 0.001 s. For optimizing the processing conditions, the control of the heating time with response time shorter than 0.001 s and the control of temperature at the level of several degrees are necessary. Thus, there has been a demand for the development of a new measurement technology that enables in situ measurement of the temperature changes on the wafer surfaces during the heat treatment process.

AIST promotes research on temperature-measurement technologies based on thermal radiation (radiation thermometry), as well as development and dissemination of national standards for this purpose. Radiation thermometry is widely used in the industrial and scientific fields as a non-contact measuring method of the surface temperature of an object. On the other hand, since this technology is based on the temperature-dependent radiation of infrared light or visible light, the following technical challenges are faced in adopting this technology: dependence on the characteristics (emissivity) of the object surface and deterioration of measurement accuracy due to light from the surrounding environment (background radiation).

Now, AIST proposes a method to compensate for the emissivity by polarized reflection measurement and a technology to suppress background radiation from the flash lamps used for heating. AIST, in collaboration with Selete, SCREEN, and CHINO, has developed a wafer-surface-temperature monitoring system with high measurement accuracy. This system can be used on a flash lamp annealing system.

In the flash lamp annealing method, temperature measurement of the wafer surface requires 1) determination of the temperature rapidly changing up to above 1000 °C with measurement intervals of less than 0.001 s and 2) contactless in situ measurement. The infrared radiation thermometer appears to be a promising fundamental instrument that meets these requirements. However, in order to use an infrared radiation thermometer in an actual flash lamp annealing apparatus, it was necessary to solve the following two problems: 1) presence of background radiation due to strong light emission from the xenon lamps used for heating and 2) changes in the wafer surface characteristics (emissivity) with temperature.

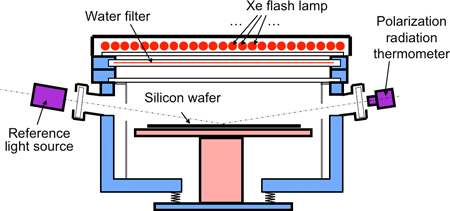

In the currently developed system, a water filter layer is placed between the xenon lamps and the wafer in order to prevent the background radiation from the xenon lamps. Because of the water characteristics, the layer absorbs a part of the infrared light (wavelength region of an absorption band of water) in order to remove a part of the infrared light while transmitting the visible light. Since the silicon wafer is heated by the absorption of visible light, the performance of the xenon lamps as heating light sources is not deteriorated. On the other hand, accurate temperature measurement that is not affected by the light emission from the xenon lamps is realized by properly matching the measurement wavelength of the infrared radiation thermometer with the wavelength of the absorption band of water.

Further, in order to solve the problem of temperature-induced changes in the emissivity of the wafer surface, we have introduced an emissivity compensation method based on polarized reflection measurement. For high-speed, simultaneous measurement of radiance temperature and reflection coefficient, we have developed a high-speed infrared radiation thermometer of a polarization detection type, as well as a high-frequency blinking (less than 0.001 s) and high-intensity reference light source. The infrared radiation thermometer can measure the intensities of p-polarized light (the electric vector of light is perpendicular to the wafer surface) and s-polarized light (the electric vector of light is parallel to the wafer surface). It measures thermal radiation from the wafer surface when the reference light source is off and measures the thermal radiation along with the light from the reference light source reflected at the wafer surface when the reference light source is on. In this manner, we can obtain the p-polarized and s-polarized light components of the thermal radiation and reflected light, respectively, to determine the emissivity of the wafer surface and measure the intensity of the thermal radiation. From both sets of results, we can measure the temperature of the wafer surface after compensating for the emissivity.

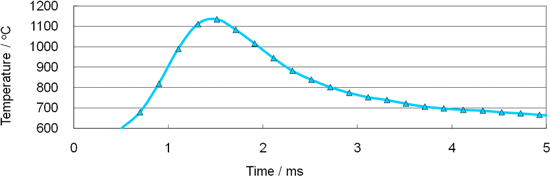

The figure below shows the temperature change of the silicon wafer surface during flash lamp heating, as measured by the method based on the technology mentioned above.

|

|

Fig: Measured values for the surface temperature of the wafer being heated in a flash lamp annealing apparatus |

The measurement data demonstrate how the wafer surface temperature rises above 1100 °C in approximately 0.001 s and then drops rapidly.

SCREEN and CHINO are carrying out technical development for practical application and commercialization of the temperature monitoring system.

We are trying to further develop our temperature-measurement technology for applications in various high-temperature processes in industries including silicon processes other than the flash lamp annealing method.