Kazuki Tajima (Research Scientist) and his co-workers at the Energy Control Thin Film Group (Leader: Kazuki Yoshimura), the Materials Research Institute for Sustainable Development (Director: Mamoru Nakamura) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa) have developed a flexible switchable mirror film that can be electrically switched between reflective and transparent states.

The newly developed all-solid-state switchable mirror film operates as an electrochromic system using electricity. Because it uses only electricity and does not require any special control system, the initial costs for the introduction of the switchable mirror film are low. The film is made entirely of solid materials, and thus offers an easy handling, etc.

The film can also be used in privacy glass or security equipment because, in its reflective state, it prevents the inside of a building or vehicle from being seen from the outside. A technique has been developed for laminating these switchable layers on a film, and a 100-micrometer-thick electrochromic switchable mirror film has been produced. The new product is more easily produced, has a better economic efficiency, is more easily recyclable, and is more easy handling than existing switchable mirror films formed on glass. As the switchable mirror film can be stuck on already built window glass, the range of applications of this film was expanded dramatically.

Demonstration ; from transparent state to mirror state |

|

Demonstration ; from mirror state to transparent state

|

Window glass allows visible light to enter buildings, but it reduces the thermal insulation between the interior and exterior because it allows transmission of heat as well as visible light. The use of double-insulating glass and heat-reflecting glass, which possess a high degree of thermal insulation, has recently become widespread, but glass that can regulate the amount of light entering a room from the outside is needed to improve the energy-saving effect. Switchable glass can satisfy this requirement.

Some electrochromic switchable glasses that can control light transmission in response to electrical signals have been commercialized. However, conventional electrochromic glass absorbs light by changing color from transparent to dark blue. Because the glass absorbs light, and therefore energy, it becomes hotter, and this heat is reradiated inside the room. To solve this problem, it is necessary to control light not by means of absorption but by means of reflection. The switchable mirror performs this function by switching from a transparent film state to a reflective mirror state. When used as window glass, it will block light effectively and reduce the cooling load inside a building or vehicle.

There are two methods for switching a switchable mirror. One is the gasochromic method for switching by exposing a mirror to gas with small amount of hydrogen; the other is the electrochromic method, in which a mirror is switched electrically. For the gasochromic method, Materials Research Institute for Sustainable Development of AIST has successfully produced a switchable mirror glass that can be built into actual buildings (see press release of December 21, 2006) and has reached the stage of demonstrating its energy-saving performance.

However, although they are easy to make in large pieces because of their simple structure, switchable mirrors using the gasochromic method require hydrogen to switch state. An electrochromic switchable mirror that can be switched electrically is urgently needed for some uses. Also the technology for forming a switchable mirror on flexible film rather than glass is highly desirable because this would expand the range of potential applications dramatically and reduce costs considerably.

This research and development was conducted with support from the “Development of Switchable Mirror Film” project as part of the “Project for Strategic Development of Rationalization Technology for Energy Usage” of New Energy and Industrial Technology Development Organization (NEDO).

The newly developed switchable mirror film can be switched between a mirror state and transparent state by applying a voltage of several volts, and it remains in its switched state even when the power is cut. (Figure 1)

|

|

|

|

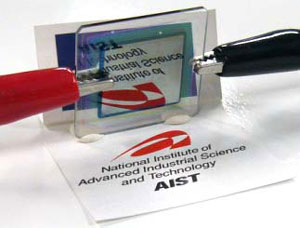

Fig. 1 All-solid-state switchable mirror on glass substrate in mirror and transparent states

|

The switchable mirror is all-solid-state; it contains neither a liquid layer nor a gas layer. It can be built on flexible substrates such as plastic films, as well as on glass plates. (Figure 2) In addition, if it is stuck onto window glass, it permits effective control of the passage of solar radiation at the flick of a switch, thereby giving a reduction in the cooling load inside buildings or cars.

|

|

|

|

Fig. 2 Flexible all-solid-state switchable mirror film

|

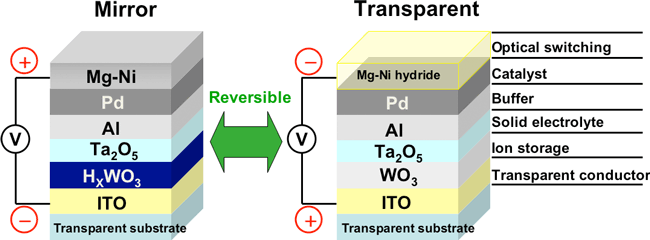

Figure 3 shows the basic structure of the newly developed switchable mirror, which is an all-solid-state product with neither a liquid layer nor a layer of a gas such as hydrogen. Indium tin oxide (ITO), tungsten oxide (WO3), tantalum oxide (Ta2O5), aluminum (Al), palladium (Pd), and magnesium and nickel alloy (Mg-Ni alloy) thin films are laminated to a glass plate or a flexible substrate such as a plastic film. These layers function, respectively, as a transparent conductive film, an ion-storage layer, a solid electorate layer, a buffer layer, a catalyst layer, and a switchable mirror layer. All the thin-film are produced by the magnetron sputtering process at room temperature. Production of the films in this manner carries a low environment load because all the processes involved can be performed at room temperature.

|

|

Fig. 3 Layer structure of all-solid-state switchable mirror in transparent and mirror states

|

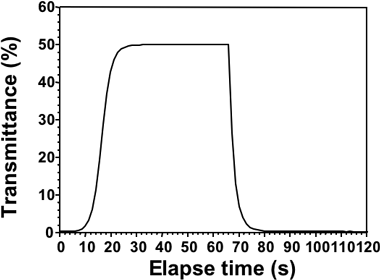

The all-solid-state switchable mirror with Mg-Ni alloy film as the switchable mirror layer is initially reflective. When the mirror is subjected to a voltage of about 5 volts, hydrogen ions (H+) stored in the ion-storage WO3 layer (HxWO3) move to the switchable mirror layer (Mg-Ni alloy in a metallic state), and metallic alloy is hydrogenated to a nonmetallic state that is transparent (Figures 3 and 4). The change takes about 15 seconds to complete.

When reversing the polarity and a voltage of about -5 volts is applied, the hydrogen ions return to the ion-storage layer (WO3) and the switchable mirror returns to its original reflective (metallic) state. This reverse change takes about 10 seconds to complete. The mirror remains in its changed state even when the power is cut off.

|

|

Fig. 4 Optical switching property of all-solid-state switchable mirror film

|

In terms of durability, we confirmed that the mirror was capable of withstanding more than 4000 cycles of switching between reflective and transparent states. The greatest breakthrough with this all-solid-state switchable mirror is that an aluminum buffer layer is inserted between the solid electrolyte layer and the catalyst layer: this buffer prevents the catalyst layer from dispersing in the solid electrolyte layer, which would otherwise cause deterioration with repeated switchovers. The presence of the aluminum layer not only markedly improves the durability of the switchable mirror, it also improves its responsiveness: in-plane current flow is facilitated because the current passes through the aluminum layer, which has an excellent electrical conductivity.

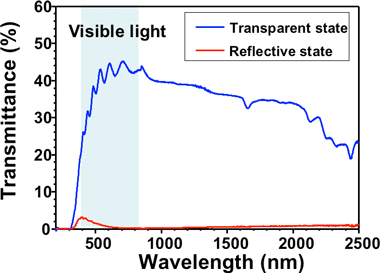

Figure 5 shows the optical transmission spectrum of the totally all-solid-state switchable mirror film. Although it allows virtually no transmission of light when it is in its mirror state, about 40% of visible and infrared light is transmitted when the switchable mirror is in its transparent state. In this way, the mirror can be switched electrically to control the amounts of both visible and infrared light that are transmitted.

|

|

Fig. 5 Optical transmittance spectra of all-solid-state switchable mirror film

|

As described above, by building the switchable mirror structure on a flexible plastic film, it can be manufactured by high-productivity methods, such as the roll-to-roll method, opening the way to larger sizes and volume production. At the same time, the range of applications for switchable mirrors is expanded dramatically, because the switchable mirror film only requires to be stuck onto windows.

We will increase the size of the all-solid-state switchable mirror film, and develop the technology to increase the durability for repeated switchovers. Because it only requires electricity to operate, the mirror has potential applications in changeover switches for optical fiber, in devices such as optical parts, goggles and sunglasses.