- Promising applications in high-density optical recording technology and as a high-performance white light source -

Sigeru Niki (Leader) of the Thin Film Compound Semiconductor Team, the Research Center for Photovoltaics (Director: Michio Kondo) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Hiroyuki Yoshikawa) (hereinafter referred to as AIST) and Hajime Shibata (Senior Research Scientist) of the Low-Temperature Physics Group, the Nanoelectronics Research Institute (Director: Toshimi Wada) of AIST have developed a semiconducting material which can efficiently emits ultraviolet light, by adding magnesium into zinc oxide to the concentration of several percent to more than ten or so percent.

The high emission efficiency of this newly developed zinc oxide semiconducting material has been accomplished by preparing a high-quality single crystalline thin film by the molecular beam epitaxy method. The light emission efficiency of the conventional ultraviolet-emitting semiconducting materials, such as gallium nitride, usually decreases with decreasing the wavelength of the emitted light. However, our newly developed material shows a remarkable increase in emission efficiency when the wavelength is decreased with increasing magnesium concentration. This newly developed material can be used for highly efficient ultraviolet light-emitting diodes, semiconductor lasers, and high-performance sources of white light.

The development of ultraviolet light-emitting diodes is strongly desired by the industrial sector as the next breakthrough after the blue-light-emitting diode. It is because the short wavelength light can provide various new functions, such as a higher optical recording density and the excitation of white-light-emitting fluorescent materials. However, the luminescence efficiency of the conventional semiconductors, including the gallium nitride that has been used in practical blue-light-emitting diodes, generally decrease with decreasing the wavelength of the emitted light, and hence it is hard to realize light emitting diodes that work in the ultraviolet wavelength region. Zinc oxide has been considered as a promising candidate for an ultraviolet-emitting semiconductor, and has been the subject of intense research efforts.

AIST has been developing a technology for the growth of high-quality zinc oxide single crystalline thin films and has also been conducting research on the precise characterization of the fundamental material properties. The objectives of the research are the realization of ultraviolet light-emitting diodes, semiconductor ultraviolet lasers, and high-performance transistors using zinc oxides. We have placed particular emphasis on the development of the molecular beam epitaxy technique for the growth of single crystalline thin films and on the characterization of the optical properties by the photoluminescence method.

Recently, we have also been developing the technology to grow high-quality epitaxial thin films of the magnesium-doped zinc oxide on zinc oxide epitaxial thin films. We also have been developing the technology of the optical characterization of the magnesium-doped zinc oxide, putting special emphasis on the photoluminescence properties.

It has been well known that the wavelength of the light emitted from the alloy of zinc oxide and magnesium oxide (hereinafter referred to as “ZnMgO”) decreases with increasing magnesium concentration. In this research, we have found that the light emission efficiency of the alloy increases with decreasing the wavelength of the emitted light, contrary to the conventional semiconductors. This new finding is mainly because we are able to produce extremely high-quality epitaxial thin films of “ZnMgO”, which had previously been very difficult to realize; we have demonstrated a real potential of “ZnMgO” that had previously been overlooked.

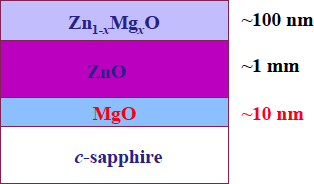

Figure 1 is a schematic illustration of the cross-sectional structure of our samples. We used sapphire single crystals as substrates, and we have grown successive layers of single crystalline MgO, ZnO, and “ZnMgO” on the substrates by the molecular-beam epitaxy method. The molecular-beam epitaxy is a method to grow single crystalline epitaxial thin films by supplying vaporized elements as the source materials in the form of molecular beams on the substrates placed in ultrahigh vacuum containers. We used extremely highly pure zinc and magnesium as the source materials for “ZnMgO”. We also used oxygen radicals for the source of oxygen.

|

|

Figure 1 Schematic illustration of the cross section of the samples |

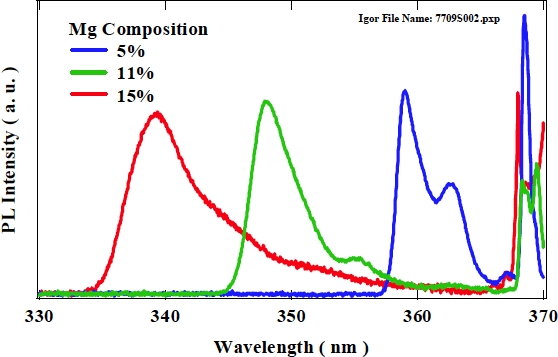

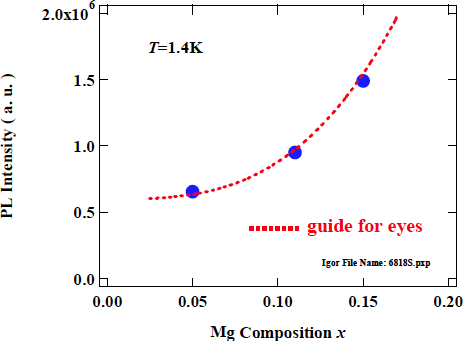

Figure 2 shows the photoluminescence spectra obtained at 1.4 K for three samples with different magnesium concentration. The ultraviolet laser light was used for the excitation. The extremely wide emission bands from “ZnMgO” layers were observed at 335 - 365 nm. Figure 3 shows the relationship between the integrated intensity of the emission band (the area under the curves) and the concentration of magnesium in the samples. The emission intensity from “ZnMgO” layers increases with increasing magnesium concentration, indicating that the addition of magnesium into zinc oxide increases the light emission efficiency remarkably.

|

|

Figure 2 Magnesium-concentration dependence of the photoluminescence emission spectra of “ZnMgO” at 1.4K |

|

|

Figure 3 Magnesium-concentration dependence of the photoluminescence emission intensity at 1.4K |

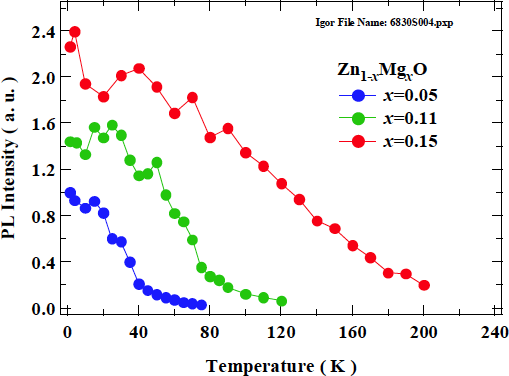

Figure 4 shows the relationships between the emission intensities from “ZnMgO” layers and the temperature of the samples: the intensity of emissions from the samples decreases gradually as their temperature is increased. It is well known, in general, the light emission efficiency of materials decreases with increasing temperature. The important fact shown in Figure 4 is that the degree of the decrease in emission efficiency becomes smaller with increasing magnesium concentration, although the emission intensity gradually decreases as the temperature of the sample is increased. This finding is very important since we usually use the light emission devices at room temperature (around 300 K).

We think that the same mechanism is responsible for the results shown in both Figure 3 and Figure 4. The mechanism of the very high light emission efficiency in gallium nitride system, for example, is believed to be due to the presence of an inhomogeneous concentration distribution of indium in the samples, and we believe that the same mechanism is responsible for “ZnMgO”. That is, the concentration of magnesium in the samples is fluctuating in space, and the light emission efficiency of the samples increases markedly due to the fluctuation. We believe that this significant increase in light emission efficiency is because of the exciton localization induced by the spatial fluctuation of the magnesium concentration.

|

|

Figure 4 Temperature dependence of the photoluminescence emission intensity. |

The basic structure of light emission devices is generally three-layered structure, where the light emitting active layer is sandwiched in between two barrier layers that block the transmission of light and electrons. The structure of the ZnO-based light emission devices which has been examined so far consists of ZnO as the active layer and “ZnMgO” as the two barrier layers. However, because we have discovered in this research that “ZnMgO” has a far higher light emission efficiency than ZnO, we are going to develop high-efficiency ultraviolet light-emitting semiconductor devices based on a design in which “ZnMgO” serves as the active layer.