Production and Utilization Technology for Hydrogen Energy Carrier

Introductory Video of Hydrogen Energy Carrier Team

"Storage and Transportation of Renewable Energy Using Hydrogen Energy Carriers"

"Storage and Transportation of Renewable Energy Using Hydrogen Energy Carriers"

Production and Use Technology for Hydrogen Energy Carriers

[ YouTube 3'00 ]

Overview

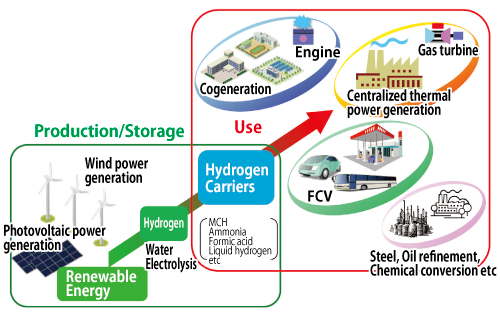

Since renewable energy is unstable and/or highly dependent on the weather and location, the amount of electric power generated by renewable energy is also unstable. The production technologies for hydrogen energy carriers are water electrolysis technology for producing hydrogen using such unstable electric power, and chemical energy conversion technology for electrolyzed hydrogen using a catalyst. These technologies are necessary in order to introduce a large amount of renewable energy.

Research Target

The team has been developing technologies for storing and utilizing large amounts of renewable energy that will help solve several energy issues facing Japan.

We have been developing technologies for converting renewable electricity into hydrogen or hydrogen energy carriers, which is utilized for generating electricity, heat, and hydrogen. These technologies are useful for stabilizing the power grid even when massive amounts of renewable energy are introduced in the future. The result will be an efficient use of a much greater amount of renewable energy regardless of the location and season.

【Fig. 1】Electricity storage applications and technologies

【Fig. 1】Electricity storage applications and technologies

Research Outline

The team has been developing a set of hydrogen technologies using electric power generated by fluctuating renewable energy: hydrogen production by water electrolysis, chemical conversion to a hydrogen energy carrier, and utilization of hydrogen. Basic technologies such as production of hydrogen energy carriers and the catalysts, and hydrogen engines are applied to large-scale demonstration equipment, and the knowledge gained through the experiments will lead to technical breakthroughs:

- Technologies for high-efficiency production of hydrogen energy carriers (e.g. organic chemical hydride, ammonia, formic acid). We are developing high-efficiency technologies for catalyst synthesis.

*Methylcyclohexane (MCH): Organic compound containing 6wt% hydrogen, which is liquid at room temperature and atmospheric pressure. One liter of MCH can store 500 L of hydrogen gas.

*Ammonia: Nitride containing 17wt% hydrogen, which is liquefied at room temperature and pressure of 0.86 MPa. One liter of liquid ammonia can store 1300 L of hydrogen gas.

*Formic acid: Organic compound containing 4wt% hydrogen, which is liquid at room temperature and atmospheric pressure. Formic acid is produced by synthesizing carbon dioxide and hydrogen. One liter of formic acid can store 600 L of hydrogen gas.

- Technologies on the combustion of hydrogen or hydrogen energy carriers for cogeneration engines and gas turbines.

- Demonstration of an integrated system of hydrogen production/utilization A new system to optimize the storage and utilization of electric power generated by renewable energy will be proposed through this experiment.

【Fig. 2】Production and utilization of hydrogen from renewable energy

【Fig. 2】Production and utilization of hydrogen from renewable energy

Activities and Achievements

Development of Dynamic Simulator of Alkaline Water Electrolyzer (Fig. 8)

It is significantly important to predict the possible amount of hydrogen produced by water electrolysis (WE) and to estimate durability of the WE. We have developed the WE simulator which can reproduce over voltage, hydrogen production rate, WE temperature, and so on as shown in Fig. 8. Our WE simulator was developed on the basis of the experiments using a 30 Nm3/h-H2 class WE installed in FREA, while the WE has already performed with over 30 MWh of renewable electricity. The WE simulator is capable of designing various kinds of energy system including renewable energy and hydrogen energy storage.

-Development-of-Dynamic-Simulator-of-Alkaline-Water-Electrolyzer_500.gif) 【Fig. 8】Development of Dynamic Simulator of Alkaline Water Electrolyzer

【Fig. 8】Development of Dynamic Simulator of Alkaline Water Electrolyzer

Next-generation Co-generation Engine System Using Organic Chemical Hydride (Fig. 9)

We have been developing a novel engine system waste heat of which is available for dehydrogenation process of Methylcyclohexane (MCH) as shown in Fig. 9. The engine is operated by co-firing technology of diesel and hydrogen generated in dehydrogenation process of MCH. It is aimed at a simultaneous achievement of adequate exhaust temperature for dehydrogenation, high thermal efficiency, clean emissions, and stable combustion.

As biomass derived fuel is used instead of diesel fuel, this system could be operated by only renewable energy.

-Next-generation-Co-generation-Engine-System-Using-Organic-Chemical-Hydride_500.gif) 【Fig. 9】Next-generation Co-generation Engine System Using Organic Chemical Hydride

【Fig. 9】Next-generation Co-generation Engine System Using Organic Chemical Hydride

Ammonia Synthesis (Fig. 10)

Research has been conducted on synthetic catalyst and process for generating ammonia made from nitrogen and hydrogen produced by water electrolysis using renewable electricity. Unlike conventional chemical plant, the operation at the constant reaction condition is hard. Therefore, synthetic catalyst is required to have catalytic activation under various conditions of temperature, pressure, hydrogen ratio, and space velocity as shown in Fig. 10, to respond to the intermittent variation of renewable electricity. This research will contribute to realizing efficient storage and utilization of renewable energy.

-Ammonia-Synthesis_500.gif) 【Fig. 10】Ammonia Synthesis

【Fig. 10】Ammonia Synthesis

Ammonia Direct Combustion Technology (Fig. 11)

We have been collaborating with Tohoku University on technology research for the direct combustion of ammonia. Work has been done on a micro gas turbine (rated power: 50 kW), and successfully achieved power generation by burning methane-ammonia or 100 % ammonia as shown in Fig. 11. We are now aiming at further reduction of nitrogen oxides by means of ammonia rich-lean two zone combustion concept and a newly developed de-NOx catalyst. *A part of the research and development was conducted under the Cross-Ministerial Strategic Innovation Program (SIP) “Energy Carrier” of the Cabinet Office (management corporation: JST).

Ammonia-Direct-Combustion-Technology_500.gif) 【Fig. 11】Ammonia Direct Combustion Technology

【Fig. 11】Ammonia Direct Combustion Technology

Team Member

| Title |

Name |

| Leader |

Taku Tsujimura |

| Senior Researcher |

Hirokazu Kojima |

| Researcher |

Yuichi Manaka |

| Researcher |

Javaid Rahat |

| Researcher |

Dimitriou Pavlos |

| Researcher |

Okafor Ekenechukwu |